Method for producing high-strength sound and heat insulation refractory bricks from complete recycled materials

A technology of thermal insulation refractory bricks and full recovery, applied in the field of refractory materials, can solve the problems of high energy consumption, high price, unsuitable for the field of civil buildings, etc., and achieves the effect of good effect, low cost and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

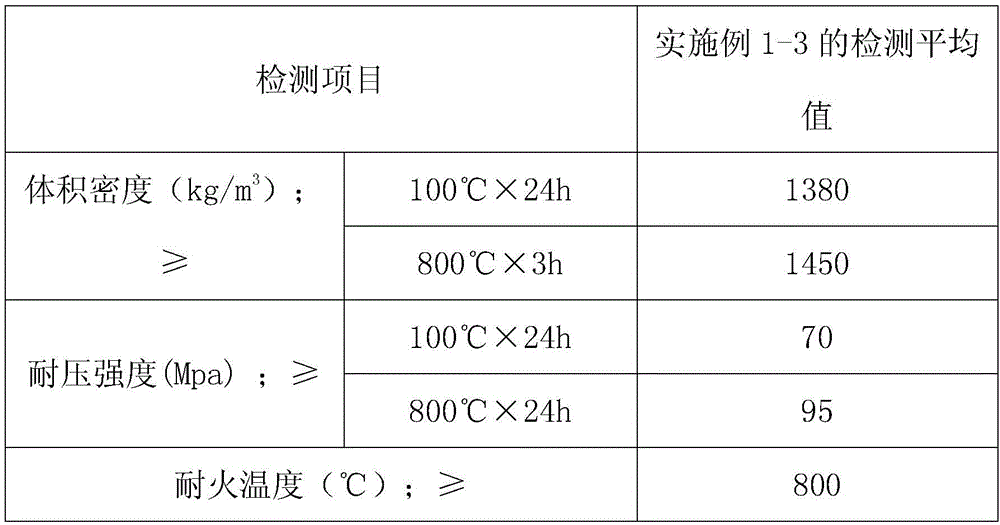

Examples

Embodiment 1

[0021] The present invention proposes a method for preparing high-strength sound-insulating and heat-insulating refractory bricks from fully recycled materials, which includes the following steps:

[0022] Step 1: After repeated mechanical crushing of the refractory bricks from the recycled steel plant, pass through a 200-mesh sieve, take the sieve to make refractory brick fine powder; pass through a 50-mesh sieve, take the sieve to make refractory brick particles;

[0023] Step 2: Make the straw into 20-40cm long section, use heavy rolling to eliminate the stress of the straw, repeatedly crush the straw, and finally become thin strips below 3cm;

[0024] Step 3: Stir the papermaking white mud slag, straw thin strips and refractory brick particles evenly, press and shape it on a brick press under the pressure of 200T, and make A-layer prefabricated bricks of sound-insulating and heat-insulating refractory bricks; the A-layer prefabricated bricks The thickness is 5cm, and the l...

Embodiment 2

[0032] The present invention proposes a method for preparing high-strength sound-insulating and heat-insulating refractory bricks from fully recycled materials, which includes the following steps:

[0033] Step 1: After repeated mechanical crushing of the refractory bricks from the recycled steel plant, pass through a 200-mesh sieve, take the sieve to make refractory brick fine powder; pass through a 50-mesh sieve, take the sieve to make refractory brick particles;

[0034] Step 2: Make the straw into 20-40cm long section, use heavy rolling to eliminate the stress of the straw, repeatedly crush the straw, and finally become thin strips below 3cm;

[0035] Step 3: Stir the papermaking white mud slag, straw thin strips and refractory brick particles evenly, press and shape it on a brick press under the pressure of 200T, and make A-layer prefabricated bricks of sound-insulating and heat-insulating refractory bricks; the A-layer prefabricated bricks The thickness is 3cm, and the l...

Embodiment 3

[0042] The present invention proposes a method for preparing high-strength sound-insulating and heat-insulating refractory bricks from fully recycled materials, which includes the following steps:

[0043] Step 1: After repeated mechanical crushing of the refractory bricks from the recycled steel plant, pass through a 200-mesh sieve, take the sieve to make refractory brick fine powder; pass through a 50-mesh sieve, take the sieve to make refractory brick particles;

[0044] Step 2: Make the straw into 20-40cm long section, use heavy rolling to eliminate the stress of the straw, repeatedly crush the straw, and finally become thin strips below 3cm;

[0045] Step 3: Stir the papermaking white mud slag, straw thin strips and refractory brick particles evenly, press and shape it on a brick press under the pressure of 200T, and make A-layer prefabricated bricks of sound-insulating and heat-insulating refractory bricks; the A-layer prefabricated bricks The thickness is 7cm, and the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com