Preparation method of high-purity kobutrol calcium

A high-purity technology of calbutril calcium, applied in the field of medicine, can solve problems such as difficulty in obtaining high-purity ligands, failure to obtain ligand crystals, large industrial wastes, etc., to achieve easy industrial application, reduce the generation of wastes, and clear routes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

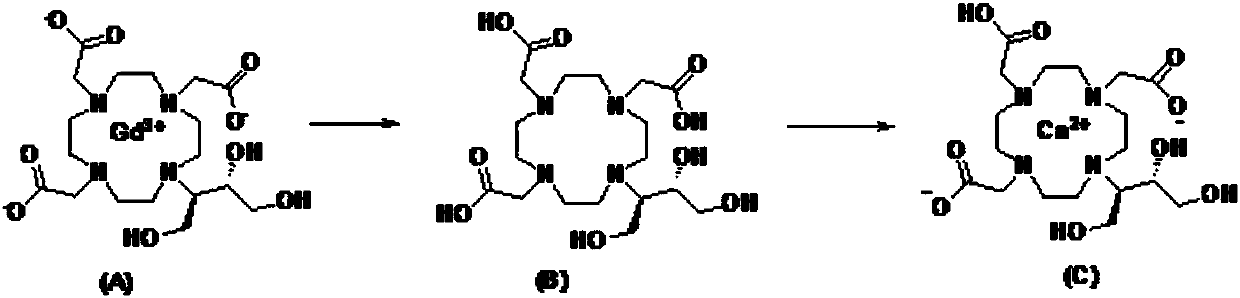

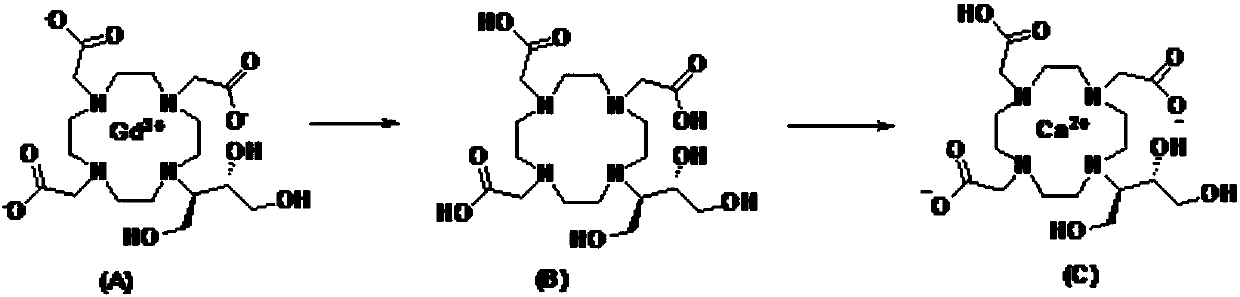

Image

Examples

Embodiment 1

[0039] At room temperature, take 10 g of gadobutrol (purity ≥ 99%) and add it to the reactor, add 100 ml of purified water and stir to dissolve, add 14.9 g of oxalic acid, heat up to 95 ° C and stir for 6 h to remove gadolinium, cool to room temperature, filter, add 16.5 g of the filtrate g calcium carbonate was refluxed for 5 hours, cooled to room temperature and filtered, the filtrate was added with 1500mL of ethanol to reflux and crystallized for 3 hours, cooled to room temperature, filtered out the crystals, rinsed with an appropriate amount of ethanol, and the filter cake was vacuum-dried at 50°C for 5 hours to obtain Cobutrol Calcium 6.2g, yield 78%, HPLC detection purity 99.8%.

Embodiment 2

[0041] At room temperature, add 50 g of gadobutrol (purity ≥ 99%) into the reactor, add 500 ml of purified water and stir to dissolve, add 74.5 g of oxalic acid, raise the temperature to 90° C. and stir to remove gadolinium for 6 hours. Cool to room temperature, filter, add 82.6g of calcium carbonate to the filtrate to reflux for 5 hours, cool to room temperature and filter, add 7500mL ethanol to the filtrate to reflux and crystallize for 3 hours, cool to room temperature, filter out the crystals, rinse with an appropriate amount of ethanol, and place the filter cake at 50°C After vacuum drying for 5 hours, 33.5 g of Calcium Cobutrol was obtained with a yield of 82.9% and a purity of 99.5% by HPLC.

Embodiment 3

[0043] At room temperature, take 50g of gadobutrol (purity ≥ 99%) into the reactor, add 500ml of purified water and stir to dissolve, add 150g of oxalic acid, heat up to 100°C and stir for 6 hours to remove gadolinium, cool to room temperature, filter, add 82.6g of filtrate Calcium carbonate was refluxed for 5 hours, cooled to room temperature and filtered, and 7500 mL of ethanol was added to the filtrate to reflux for crystallization for 3 hours, cooled to room temperature, the crystals were filtered out, rinsed with an appropriate amount of ethanol, and the filter cake was vacuum-dried at 50°C for 5 hours to obtain 32.1 g, yield 79.5%, the HPLC detection purity is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com