Manganese-doped Li<2>FeSiO<4>/graphene hollow nanosphere cathode material and preparation method thereof

A cathode material, hollow nanotechnology, which is applied in the fields of material synthesis and electrochemistry, can solve the problems of unfavorable electron transport, large deformation of materials, poor electronic conductivity, etc., and achieves the effect of simple and easy-to-obtain method, good dispersibility, and improved capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

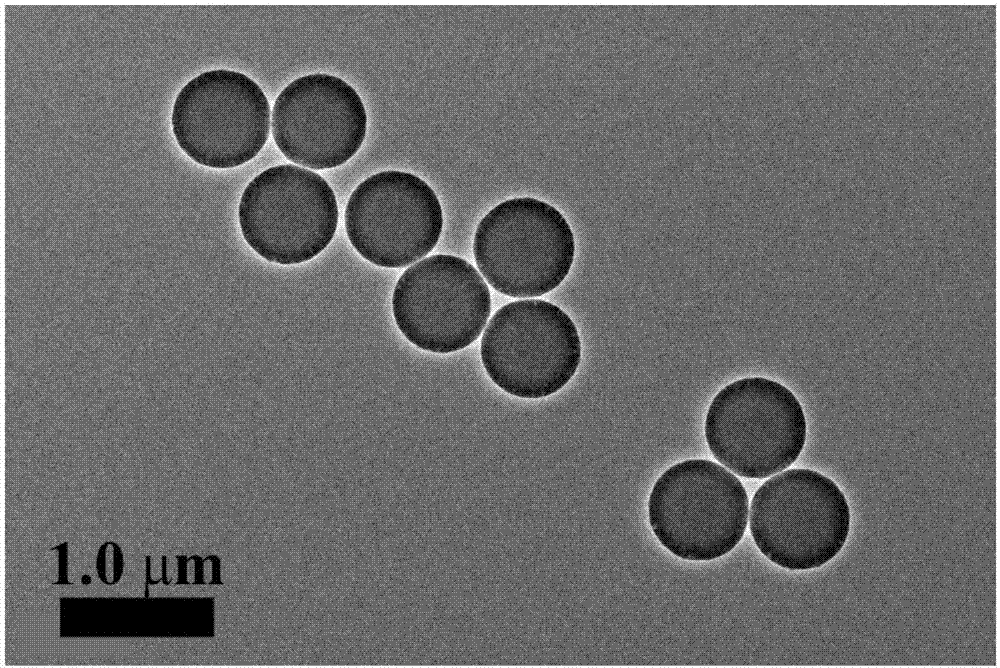

[0043] Li in this example 2 FeSiO 4 The preparation steps of @graphene hollow nanosphere cathode material are as follows:

[0044] 1. Use an electronic balance to weigh 0.3g polyvinylpyrrolidone (PVP, Sigma, Mw≈55000) dispersant and ultrasonically dissolve it in 200mL deionized water to form a transparent solution A, during which time N 2 Deoxygenation for half an hour;

[0045] 2. Use an electronic balance to weigh 20g of styrene and slowly drop into solution A to form solution B, and heat up to 70°C;

[0046] 3. Use an electronic balance to weigh 0.4g initiator (V-50) and dissolve it in 2.5mL deionized water, and slowly add it to solution B to form a milky white solution. 2 Emulsion polymerization in air for 24 hours to generate polystyrene microsphere emulsion;

[0047] 4. The polystyrene microsphere emulsion was centrifugally washed 6 times with deionized water, and dried to obtain polystyrene microsphere white powder (PS)D;

[0048] 5. TEOS:CTAB:CH based on Mole rati...

Embodiment 2

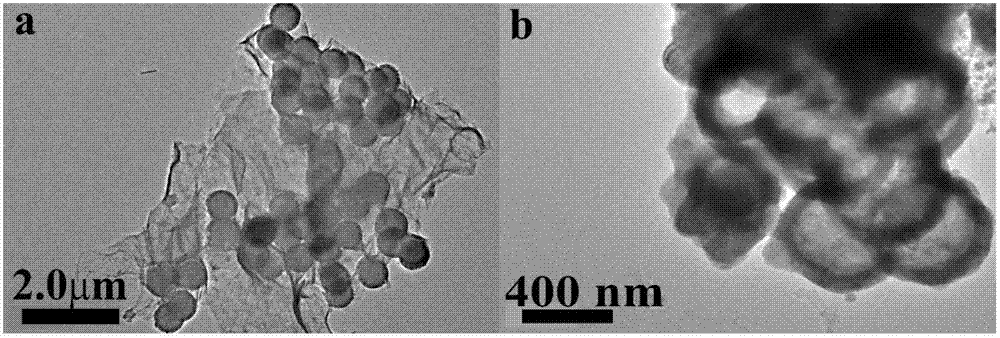

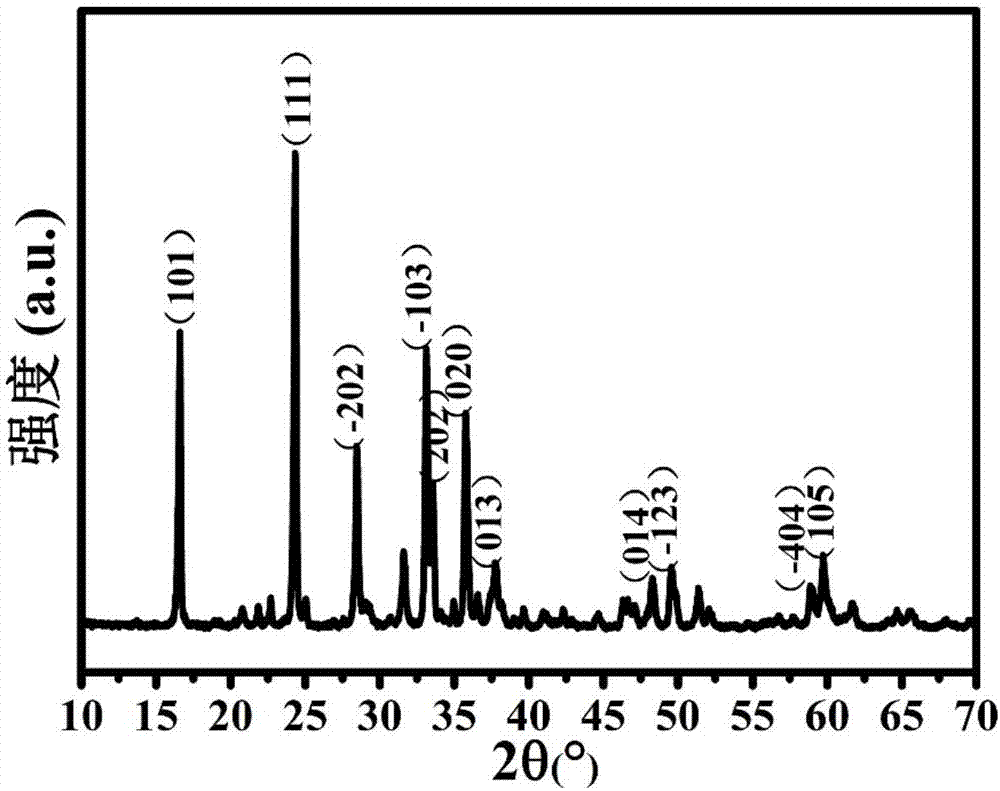

[0057] Li in this example 2 Fe 0.8 mn 0.2 SiO 4 The preparation steps of @graphene hollow nanosphere cathode material are as follows:

[0058] 1. Use an electronic balance to weigh 0.3g polyvinylpyrrolidone (PVP, Sigma, Mw≈55000) dispersant and ultrasonically dissolve it in 200mL deionized water to form a transparent solution A, during which time N 2 Deoxygenation for half an hour;

[0059] 2. Use an electronic balance to weigh 20g of styrene and slowly drop into solution A to form solution B, and heat up to 70°C;

[0060] 3. Use an electronic balance to weigh 0.4g initiator (V-50) and dissolve it in 2.5mL deionized water, and slowly add it to solution B to form a milky white solution. 2 Emulsion polymerization in air for 24 hours to generate polystyrene microsphere emulsion;

[0061] 4. The polystyrene microsphere emulsion was centrifugally washed 6 times with deionized water, and dried to obtain polystyrene microsphere white powder (PS)D;

[0062] 5. According to the ...

Embodiment 3

[0068] Li in this example 2 Fe 0.7 mn 0.3 SiO 4 The preparation steps of @graphene hollow nanosphere cathode material are as follows:

[0069] 1. Use an electronic balance to weigh 0.3g polyvinylpyrrolidone (PVP, Sigma, Mw≈55000) dispersant and ultrasonically dissolve it in 200mL deionized water to form a transparent solution A, during which time N 2 Deoxygenation for half an hour;

[0070] 2. Use an electronic balance to weigh 20g of styrene and slowly add it dropwise to solution B, and raise the temperature to 70°C;

[0071] 3. Use an electronic balance to weigh 0.4g initiator (V-50) and dissolve it in 2.5mL deionized water, and slowly add it to solution B to form a milky white solution. 2 Emulsion polymerization in air for 24 hours to generate polystyrene microsphere emulsion;

[0072] 4. The polystyrene microsphere emulsion was centrifugally washed 6 times with deionized water, and dried to obtain polystyrene microsphere white powder (PS)D;

[0073] 5. According to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com