Efficient solid screw cleaning agent and preparation method thereof

A screw cleaning agent, solid technology, applied in the field of screw cleaning agent, high-efficiency solid screw cleaning agent and its preparation, can solve the problems of endangering the health of employees, increasing the volume of cleaning materials, consuming time and manpower, etc., and achieving the improvement of cleaning residues The ability of substances, the improvement of compatibility, and the effect of improving cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

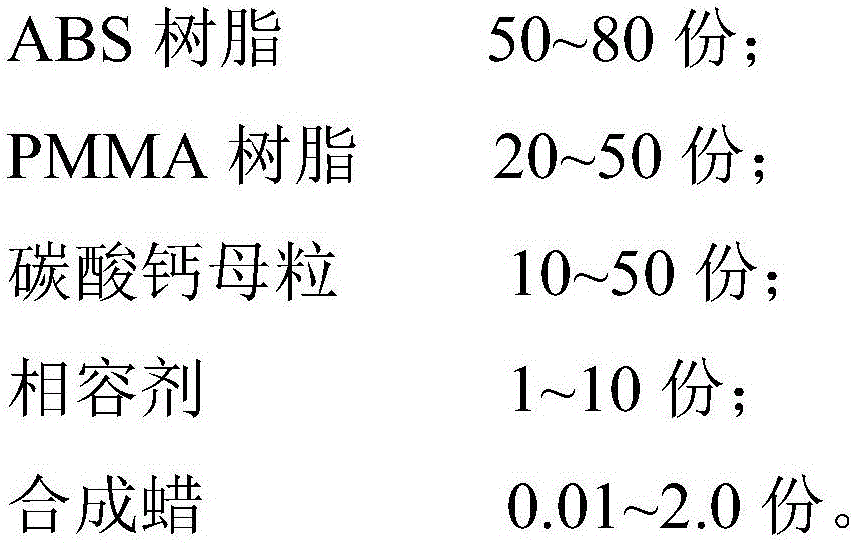

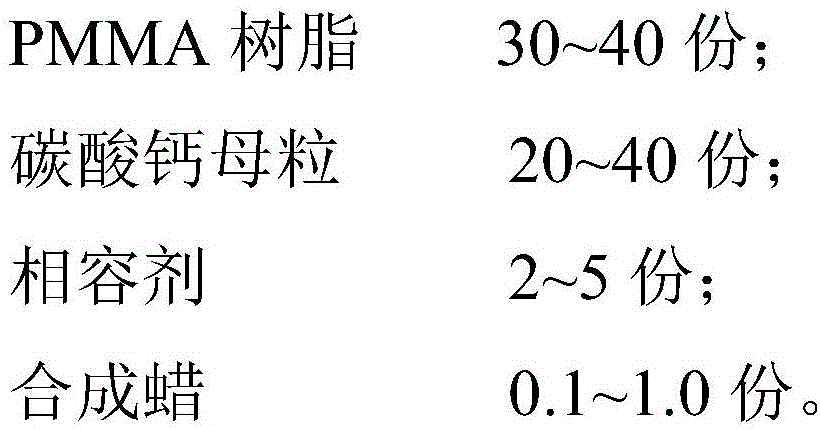

Method used

Image

Examples

Embodiment 1

[0035]Weigh 80 parts of ABS resin, 20 parts of PMMA resin, 50 parts of calcium carbonate masterbatch, 1.0 part of compatibilizer and 0.01 part of synthetic wax, add them to the mixer and mix them thoroughly for 5 minutes to obtain a premix; add the obtained premix Melt extrusion and strand granulation are carried out in a twin-screw extruder to obtain a high-efficiency solid screw cleaning agent. The temperatures in zones 1, 5, 6, 7, 8 and 9 are all 190°C respectively, and the head temperature is 190°C; and the speed of the main engine is 200rpm; wherein the twin-screw extruder is a parallel twin-screw extruder, and Its aspect ratio is 30:1.

Embodiment 2

[0037] Weigh 75 parts of ABS resin, 25 parts of PMMA resin, 45 parts of calcium carbonate masterbatch, 2.0 parts of compatibilizer and 0.1 part of synthetic wax and add them to the mixer and mix them thoroughly for 10 minutes to obtain a premix; add the obtained premix Melt extrusion and strand granulation are carried out in a twin-screw extruder to obtain a high-efficiency solid screw cleaning agent, wherein the process parameters of the twin-screw extruder are: the temperatures of the first and second zones are 170°C, and the temperatures of the third and fourth zones are respectively The temperatures in zones 1, 5, 6, 7, 8 and 9 are all 200°C respectively, and the head temperature is 200°C; and the speed of the main engine is 250rpm; wherein the twin-screw extruder is a parallel twin-screw extruder, and Its aspect ratio is 40:1.

Embodiment 3

[0039] Weigh 70 parts of ABS resin, 30 parts of PMMA resin, 40 parts of calcium carbonate masterbatch, 5.0 parts of compatibilizer and 0.5 part of synthetic wax and add them into the mixer for 10 minutes of thorough mixing to obtain a premix; add the obtained premix Melt extrusion and strand granulation are carried out in a twin-screw extruder to obtain a high-efficiency solid screw cleaning agent, wherein the process parameters of the twin-screw extruder are: the temperatures of the first and second zones are 180°C respectively, and the temperatures of the third and fourth zones are respectively The temperatures in zones 1, 5, 6, 7, 8 and 9 are all 220°C respectively, and the head temperature is 220°C; and the speed of the main engine is 500rpm; wherein the twin-screw extruder is a parallel twin-screw extruder, and Its aspect ratio is 40:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com