Method for improving oxidation resistance of carbon anode for aluminum electrolysis

An anti-oxidation, carbon anode technology, applied in the field of industrial catalysis and organic chemicals, can solve the problems of difficult coating, little blocking effect, unevenness, etc., achieve simple and easy preparation methods, improve high-temperature coking value, The effect of improving antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

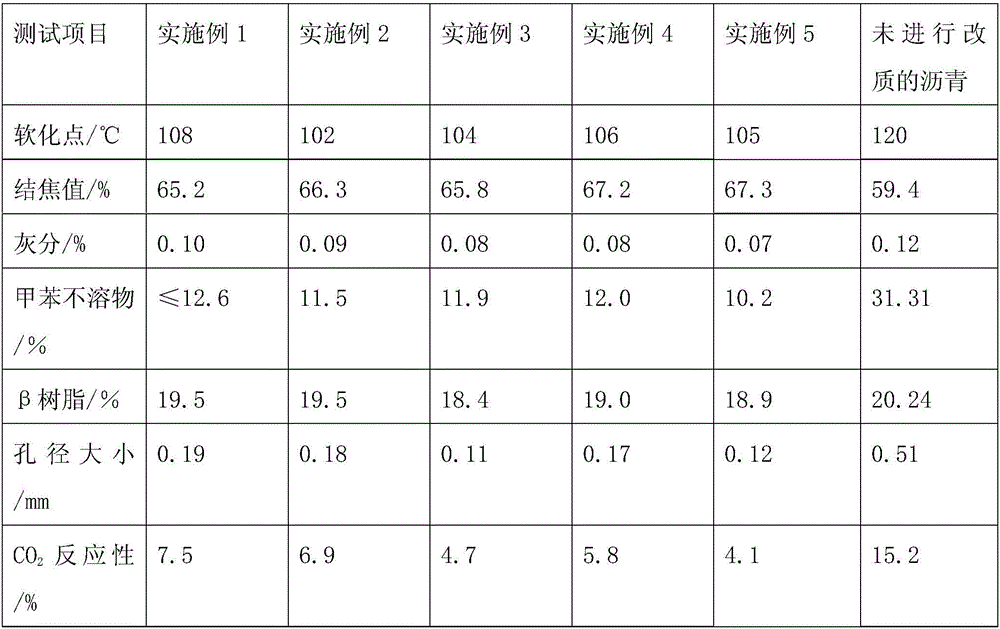

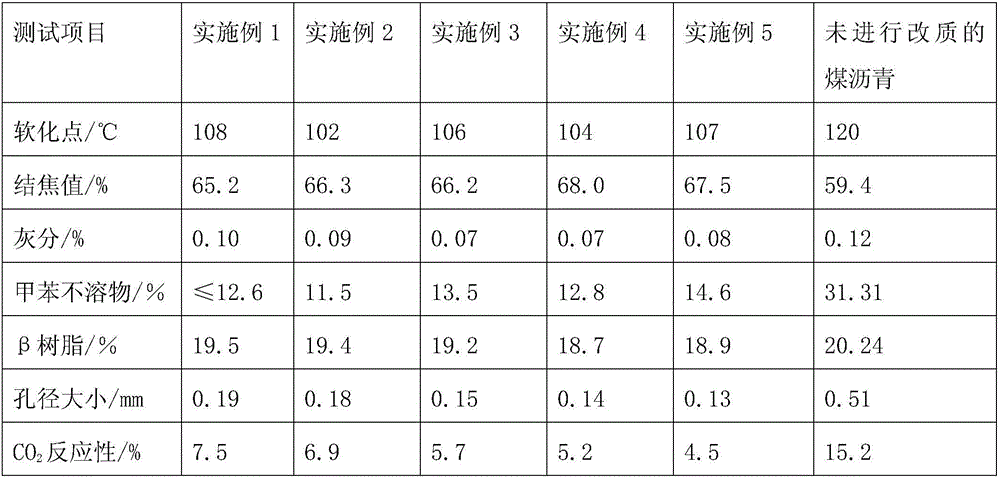

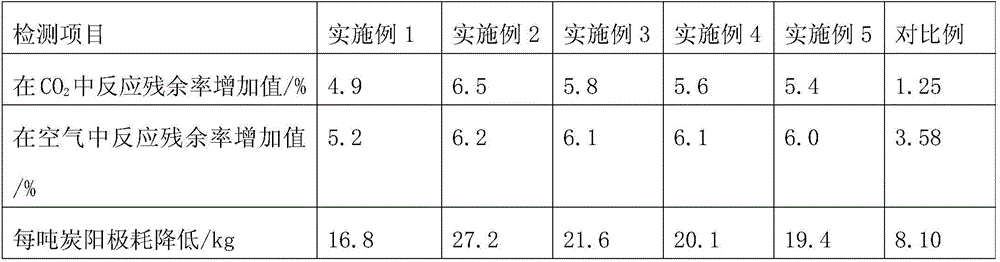

Examples

Embodiment 1

[0029] A method for improving the oxidation resistance of a carbon anode for electrolytic aluminum, comprising the following steps:

[0030] (1) Preparation of modified coal tar pitch: mix coal tar pitch and modified pitch agent A, heat up to 180°C for cross-linking and fusion for 1 min, then lower the temperature after cross-linking and fusion to 90°C, and then add modified pitch Agent B and stirred for 20 minutes, after cooling, the modified coal tar pitch can be obtained and set aside;

[0031] According to parts by weight, 50 parts of coal tar pitch, 5 parts of asphalt modifier A, and 3 parts of asphalt modifier B;

[0032] Wherein, the asphalt modifier A includes 1 part of modified diatomite and 2 parts of modified bentonite in parts by weight;

[0033] Among them, the modified diatomite is calcined at 500°C for 10 minutes, and after cooling, it is crushed by ultrasonic wave until the particle size is 100 mesh;

[0034] Among them, the modified bentonite is mechanically...

Embodiment 2

[0042] A method for improving the oxidation resistance of a carbon anode for electrolytic aluminum, comprising the following steps:

[0043] (1) Preparation of modified coal tar pitch: mix coal tar pitch and modified pitch agent A, heat up to 200°C for cross-linking and fusion for 30 minutes, then lower the temperature after cross-linking and fusion to 90°C, and then add modified pitch Add agent B and stir for 30 minutes, and after cooling, the modified coal tar pitch can be obtained and set aside;

[0044] 85 parts by weight of the coal tar pitch, 15 parts of asphalt modifier A, and 8 parts of asphalt modifier B;

[0045] Wherein, the asphalt modifier A includes 5 parts of modified diatomite and 8 parts of modified bentonite in parts by weight;

[0046] Among them, the modified diatomite is calcined at 600°C for 30 minutes, and after cooling, it can be pulverized by ultrasonic waves until the particle size is 150 mesh;

[0047] Among them, the modified bentonite is mechanic...

Embodiment 3

[0055] A method for improving the oxidation resistance of a carbon anode for electrolytic aluminum, comprising the following steps:

[0056] (1) Preparation of modified coal tar pitch: mix coal tar pitch and modified pitch agent A, heat up to 185°C for cross-linking and fusion for 15 minutes, then lower the temperature after cross-linking and fusion to 100°C, and then add modified pitch Agent B and stirred for 23 minutes, after cooling, the modified coal tar pitch can be obtained and set aside;

[0057] According to parts by weight, 55 parts of coal tar pitch, 8 parts of asphalt modifier A, 4 parts of asphalt modifier B;

[0058] Wherein, the asphalt modifier A includes 2 parts of modified diatomite and 3 parts of modified bentonite in parts by weight;

[0059] Among them, the modified diatomite is calcined at 540°C for 18 minutes, and after cooling, it can be pulverized by ultrasonic waves until the particle size is 120 mesh;

[0060] Among them, the modified bentonite is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com