Air compression device of electrical oil-free main air compressor

A technology of air compression and air compressor, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., which can solve the problems of high daily maintenance costs, oil leakage and oil leakage of air compressors, etc., and improve the service life , reduce noise, prevent vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

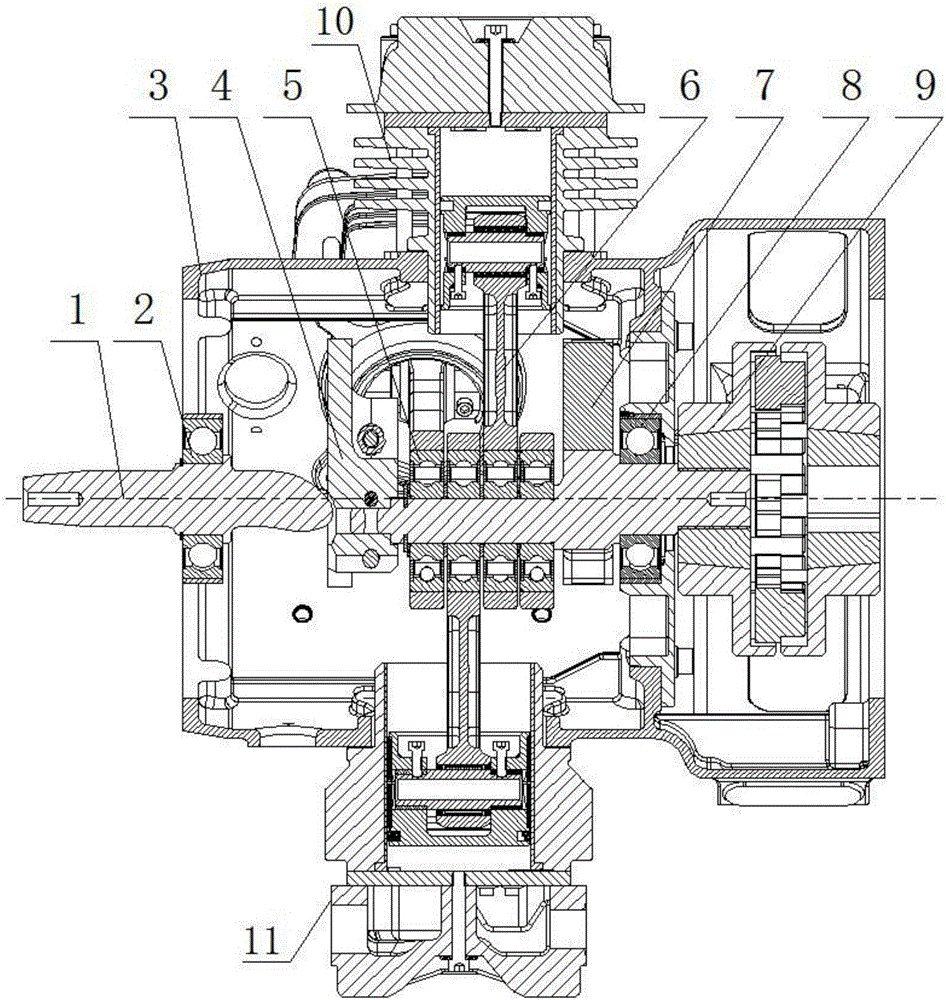

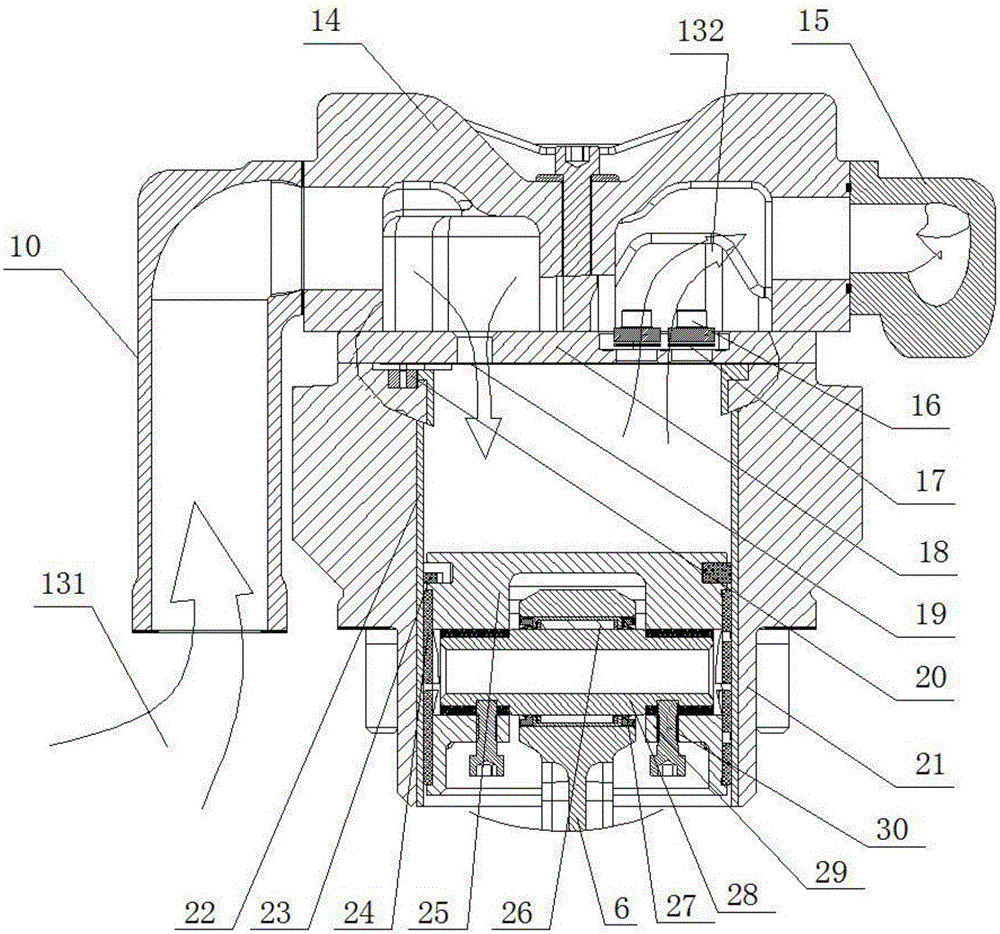

[0039] Such as figure 1 , figure 2 and image 3 As shown, the air compression device of the electric oil-free main air compressor of the present embodiment 1 includes an integral main casing 3 and a compression cylinder assembly arranged on the main casing 3 and connected to the inside of the main casing 3, the main casing Body 3 is provided with crankshaft 1, fan end bearing 2, large counterweight 4, swing rod bearing 5, swing rod 6, small counterweight 7, motor end bearing 8 and shaft coupling 9; the compression cylinder assembly consists of a low-pressure cylinder Cover 14, output joint 15, valve plate screw 16, exhaust reed 17, valve plate 18, intake reed 19, low-pressure cylinder body 21, and pad 20 set in low-pressure cylinder body 21, low-pressure cylinder Cylinder liner 22, piston ring 23, support ring 24, low-pressure piston 25, connecting rod small end bearing 26, oil seal 27, piston pin 28, heat insulating ring 29, compression screw 30; piston ring 23 and support...

Embodiment 2

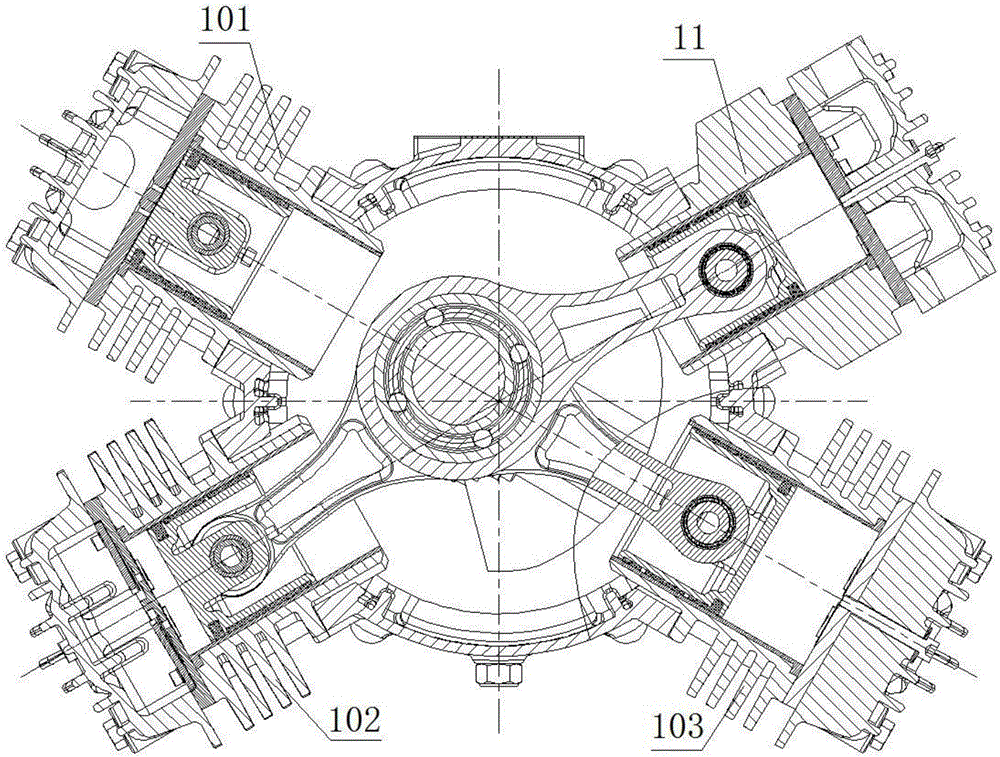

[0051] The main features of this embodiment 2 are: the compression cylinder assembly is composed of two high-pressure cylinder assemblies 11 and two low-pressure cylinder assemblies 10, and the two high-pressure cylinder assemblies 11 and two low-pressure cylinder assemblies 10 are X-shaped on the main housing 3 set up. All the other features are with embodiment 1.

[0052] In Example 1 and Example 2, as figure 1 and image 3 As shown, the rotation of the motor transmits the torque to the coupling 9, and then drives the crankshaft 1 to rotate. The fan end bearing 2 and the motor end bearing 8 provide support and fixation for the crankshaft 1. The rods 6 are all installed in this turning groove. When the crankshaft 1 rotates, the four swing rods 6 will move up and down. The swing rod bearings 5 provide support and fixation for the swing rods 6. The large counterweight 4 and the small counterweight 7 are Provide force balance during the movement of the main body of the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com