A kitchen flue gas waste heat recovery and utilization system

A flue gas waste heat and kitchen technology, applied in the field of waste heat recovery, can solve problems such as energy waste and environmental pollution, and achieve the effects of avoiding energy waste, improving safety and stability, and convenient and quick manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

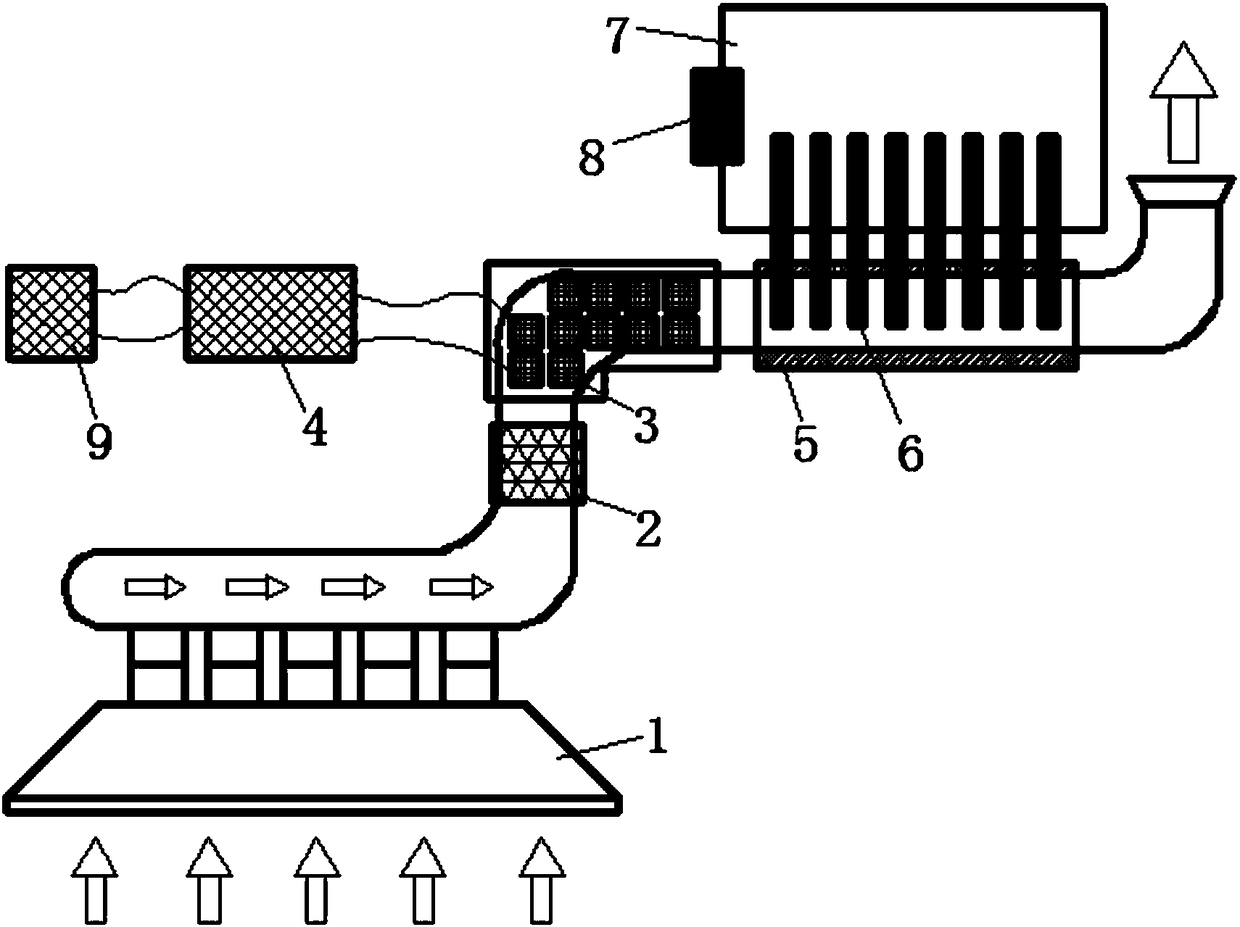

[0024] refer to figure 1 , the present invention is a waste heat recovery and utilization system of kitchen flue gas, which includes two parts. The first part is a thermoelectric power generation module, which includes thermoelectric power generation sheets 3 scattered on the wall of the pipeline and a storage battery 4 for storing electricity; the second part is a heat pipe The heat exchange module includes an insulation layer 5 wrapped outside the pipe, one end of the gravity heat pipe heat exchanger 6 is embedded in the pipe, and the other end is connected to the water tank 7 with an integrated automatic control device 8 . The self-contained parts of the system are the smoke collection box 1 and the oil fume purifier 2. Among them, the smoke collection box 1 and the oil purifier 2 remove oil stains, and then use the thermoelectric power generation sheet 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com