Precision-grade high-temperature resistant thermocoupling compensation wire for nickel chromium-nickel silicon thermocoupler

A technology for compensating wires and thermocouples, applied in conductors, circuits, insulated cables, etc., can solve the problems that the performance of compensating wires cannot meet higher quality requirements, and achieve the effects of excellent anti-aging, high precision and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

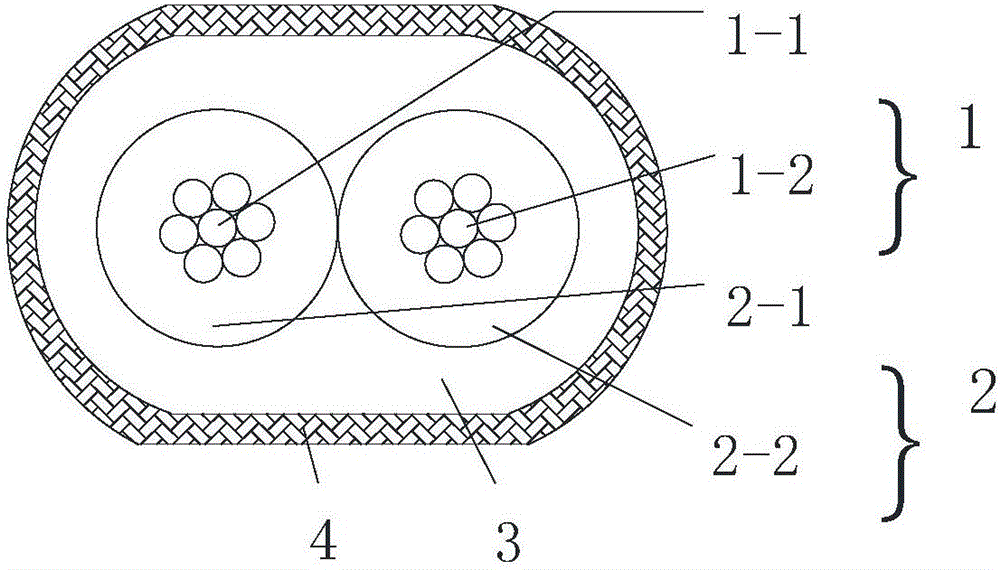

[0027] as attached figure 1 The shown nickel-chromium-nickel-silicon thermocouple uses a precision-grade high-temperature-resistant thermocouple compensation wire, including: conductor 1, the insulating layer 2 covered by the conductor 1, the sheath layer 3 outside the insulating layer 2 and the outer sheath layer 3 The shielding layer 4; the conductor 1 is composed of a positive bare copper conductor 1-1 and a negative copper-nickel conductor 1-2; the insulating layer 2 is a positive insulating layer 2- 1. The insulating layer 2 is the negative insulating layer 2-2 coated outside the negative copper-nickel conductor 1-2; the positive bare copper conductor covered with the positive insulating layer and the negative copper-nickel conductor covered with the negative insulating layer are parallel and juxtaposed Placement; the insulation layer 2 and the sheath layer 3 are high and low temperature resistant tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer materials.

Embodiment 2

[0029] On the basis of embodiment 1, the conductor structure of the nickel-chromium-nickel-silicon thermocouple of the present invention is that the bare copper conductor 1-1 of 7 / 0.43mm is the positive pole, and the conductor structure of the high-temperature resistant thermocouple compensation wire of 7 / 0.43mm Copper-nickel (the chemical composition ratio of copper and nickel is 60:40) conductor 1-2 is the negative electrode.

[0030] The insulating material of the insulating layer 2 is tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer material, the operating temperature range is -60 ° C ~ 250 ° C, the tensile strength of the insulating layer is ≥ 13.8Mpa, and the elongation of the insulating layer is ≥ 100%. The color of the positive insulation 2-1 is red, and the color of the negative insulation 2-2 is blue.

[0031] The material of the sheath layer 3 is tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer material, the service temperature range is -60°C to 2...

Embodiment 3

[0034] On the basis of embodiment 1, the preparation process of the precision-grade high-temperature-resistant thermocouple compensation wire for nickel-chromium-nickel-silicon thermocouple of the present invention is as follows:

[0035] 1. Conductor 1 stranding: Conductor 1 is stranded with stranding equipment beam machine and frame stranding machine. The annealed 7 / 0.43mm bare copper monofilament is selected to be twisted leftward according to the pitch ratio of 13 to form the positive conductor 1-1; the annealed 7 / 0.43mm copper nickel is selected (the chemical composition ratio of copper and nickel is 60:40 ) monofilaments are twisted leftward according to the pitch ratio of 13 to form the negative conductor 1-2.

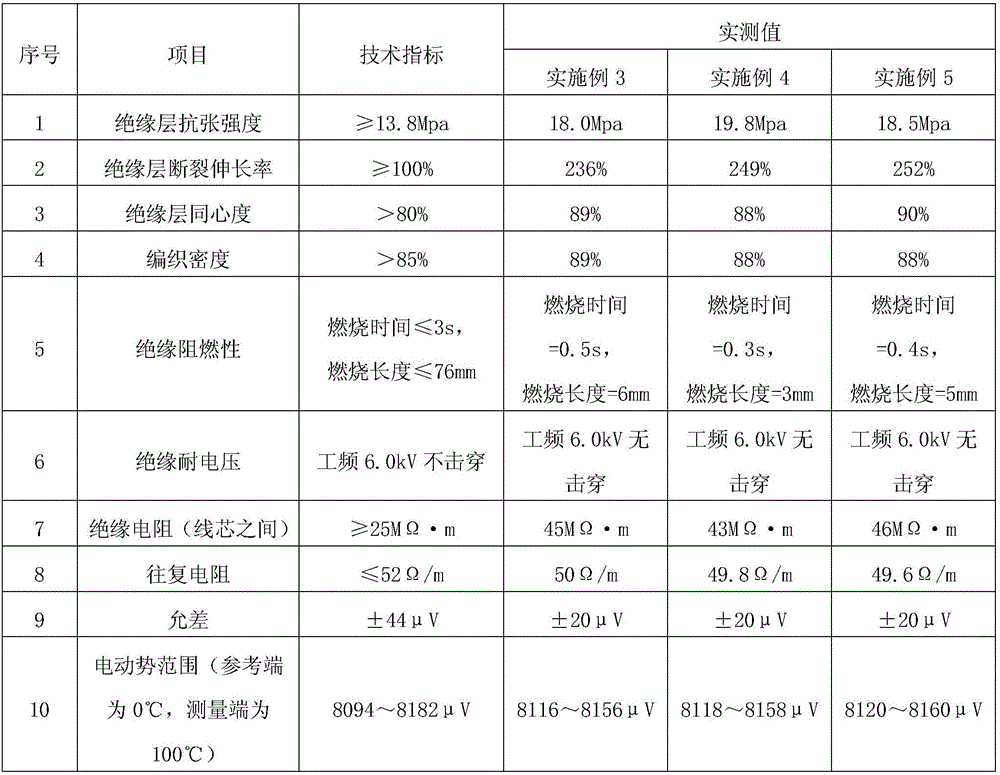

[0036] 2. Extrusion of the insulating layer 2: the insulating layer 2 is extruded with a high-temperature extruder. The insulating material is tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer material; the concentricity of the insulating layer is 88%; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Temperature class | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com