Flexible perovskite solar cell and preparation method thereof

A perovskite and insulating technology, which is applied in the field of flexible perovskite solar cells and its preparation, can solve the problems of flexible perovskite solar cells that are difficult to repeatedly bend, difficult to control the light-absorbing layer, and easily damaged by force. Achieve large-scale production, improve stability and service life, and achieve high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1, preparation flexible perovskite solar cell:

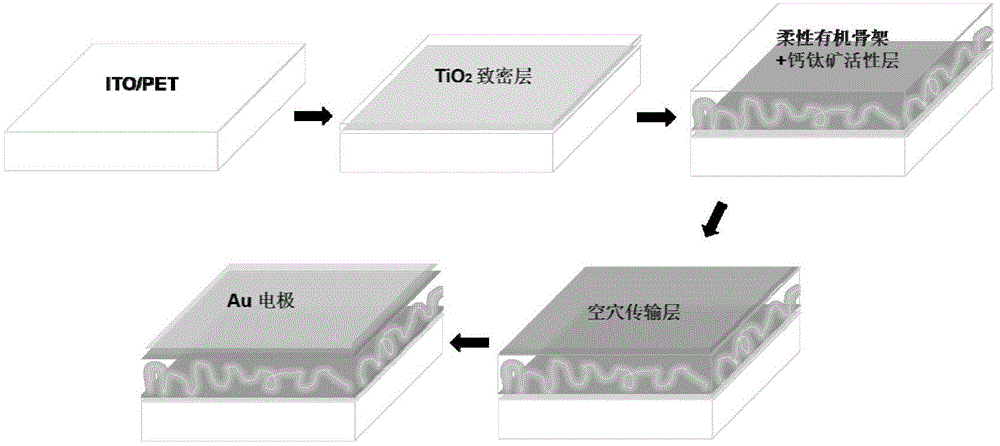

[0058] according to figure 2 The shown process flow diagram for the fabrication of flexible perovskite solar cells with organic polymers:

[0059] 1) Deposit a 20nm thick titanium oxide film on the surface of the PEN-ITO conductive film by magnetron sputtering or atomic layer deposition. Magnetron sputtering can be deposited with a current of 0.2A for 20s; atomic layer deposition is deposited 500 times;

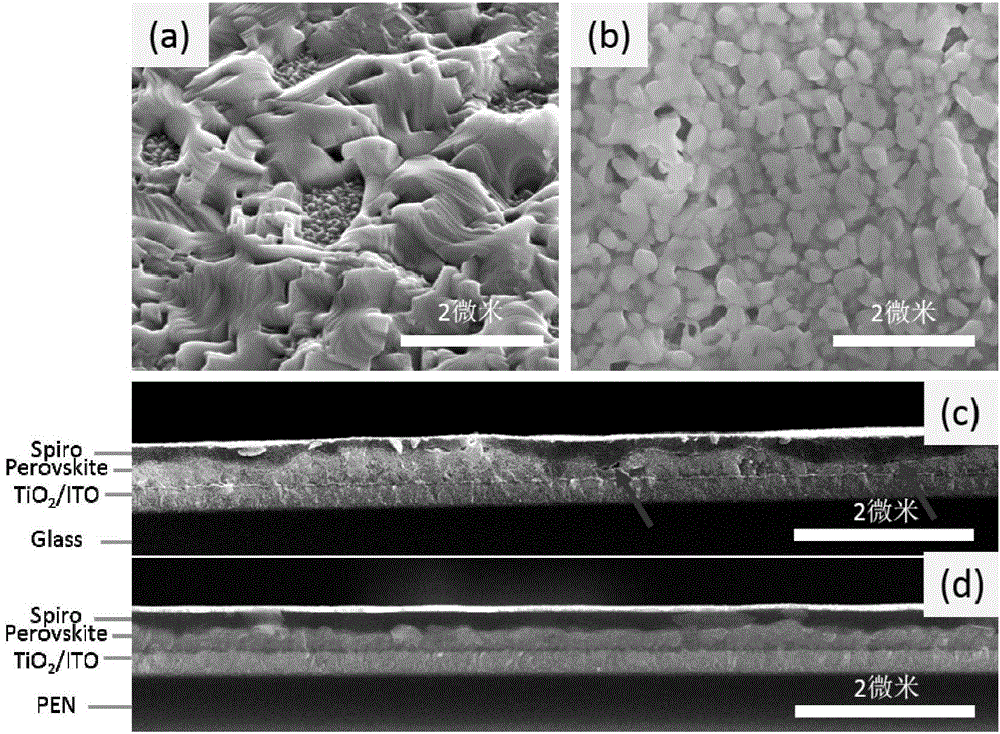

[0060] 2) Change CH 3 NH 3 I and PbCl 2 Dissolve N,N-dimethylformamide (DMF) to obtain a mixed solution, so that the molar concentrations of the two in the mixed solution are 3mol / L and 1mol / L respectively, and then add 20mg of polyethylene glycol to each milliliter of the mixed solution. Glycol (molecular weight 20000Da), make its molar concentration 0.001mol / L, stir evenly. The prepared perovskite precursor solution containing polyethylene glycol was coated with dense TiO at 4000r / min 2 Spin-coat the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com