Current cutouts used by flow battery and flow battery adopting same

A liquid flow battery and current interrupter technology, which is applied to fuel cell components, fuel cells, fuel cell additives, etc., can solve problems such as increased branch resistance, difficult installation, and excessive weight, so as to prevent bypass current, eliminate leakage current, and simplify the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

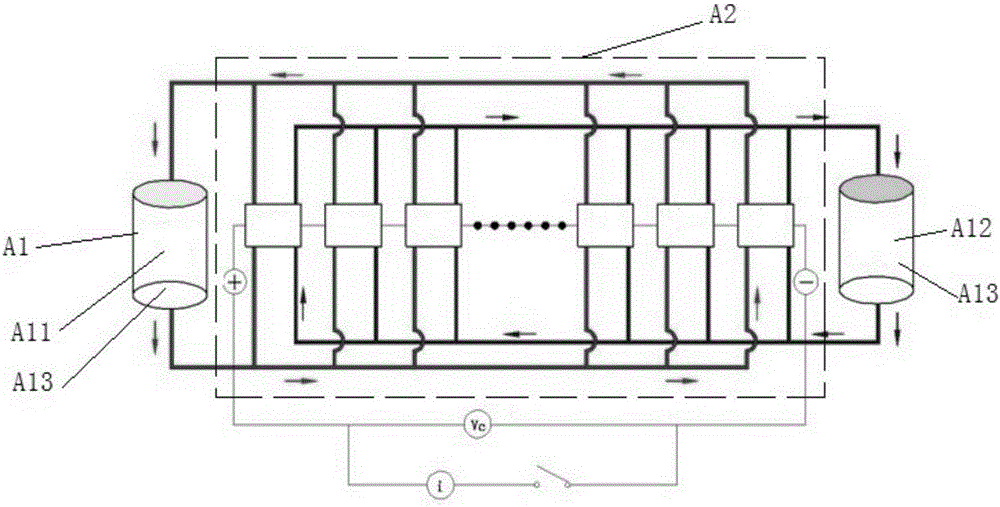

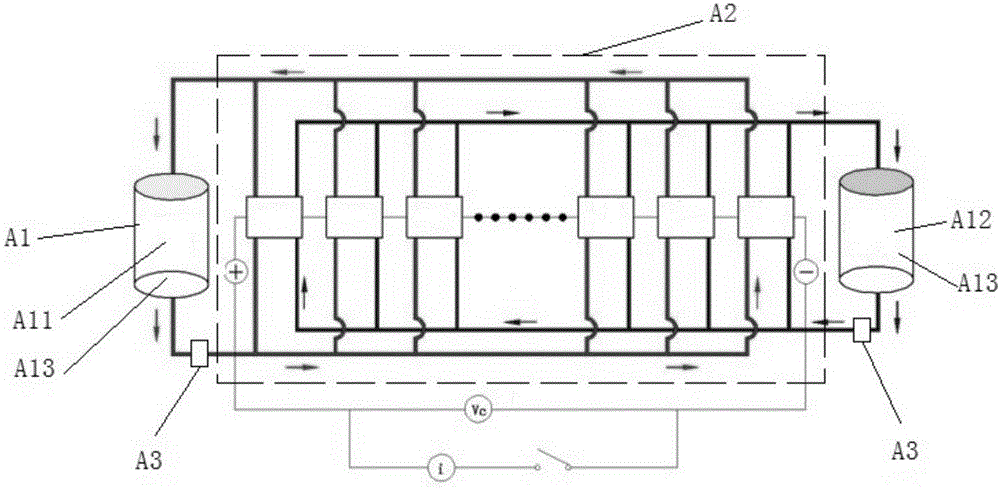

[0064] A liquid flow battery, its structural schematic diagram is shown in image 3 , specifically: including a power supply group A1 providing power for the circuit, a stack group A2 and a branch circuit arranged in series in the circuit;

[0065] The power pack A1 includes a positive electrode liquid tank A11 for storing electrolyte and a negative electrode liquid tank A12 for storing electrolyte, and the output ends of the positive electrode liquid tank A11 and the negative electrode liquid tank A12 are both provided with an electric pump A13, which is located at the On the outlet pipeline of the electric pump A13 at the output end of the positive electrode liquid tank A11 and on the outlet pipeline of the electric pump A13 at the output end of the negative electrode liquid tank A12, at least one flow battery current interrupter A3 is provided. (That is, the outlet pipelines of the two electric pumps A13 are provided with flow battery current interrupters A3, and the number...

Embodiment 2

[0072] A liquid flow battery, which is different from Embodiment 1 only in that the current interrupter for the liquid flow battery is different, see Figure 6 and Figure 7 , the details are as follows: the blade part 4.3 includes three sets of blade pieces 4.31 arranged side by side up and down, the blade piece 4.31 includes a group of blades B arranged in a spiral manner, and the blade B at the bottom includes the Tail structure A.

[0073]The working principle of the current interrupter for the flow battery of this embodiment is different from that of Embodiment 1 in that: the electrolyte flowing into the cylindrical barrel 4.1 through the liquid inlet 1.12 falls to the uppermost blade B, driving the The top blade B rotates; then it falls into the blade B on the next layer and drives it to rotate. According to this principle, the electrolyte falls on the bottom blade B and drives it to rotate. When the tail structure A overlaps with the liquid discharge port 1.22, the li...

Embodiment 3

[0076] A liquid flow battery, which is different from Embodiment 1 only in that the current interrupter for the liquid flow battery is different, see Figure 8 , the details are as follows: the electrolyte inlet pipe 2 communicates with the first cylinder 1.11 through a connecting pipe 5, and the connecting pipe 5 includes a conduit 5.1 arranged inside the rotating column 4.2 and a tube located in the first cylinder 1.11 Connection joint 5.2 in communication with said conduit 5.1.

[0077] The connection joint 5.2 is a hemispherical structure, and a plurality of through holes 5.21 are arranged on it, and the central axes of the plurality of through holes 5.21 are radially arranged.

[0078] The working principle of the current interrupter for the flow battery is different from that of Embodiment 1 only in that: the electrolyte enters the inflow guide after passing through the conduit 5.1 arranged in the rotating column 4.2 and the connecting joint 5.2 arranged at the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com