Preparation method of feeding ferrous lactate

A technology for ferrous lactate and feeding, which is applied in the fields of feed, enzyme preparations and microorganisms. It can solve the problems of high cost and heavy pollution, and achieve the effects of fast absorption, good palatability and good iron supplementation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A preparation method for feeding ferrous lactate, comprising the following steps:

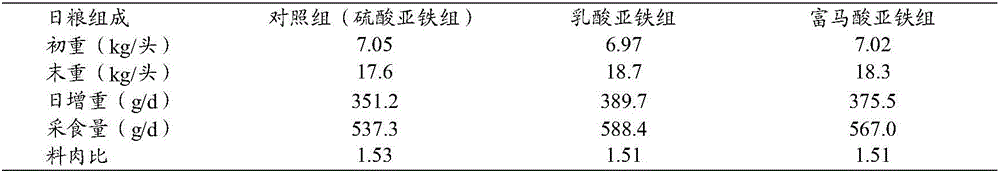

[0072] Grind 250kg of corn, add 1200kg of water to make slurry, add 0.15-0.20kg of liquefaction enzyme and glucoamylase to liquefy when the temperature is raised to 95°C, and obtain 1250kg of saccharification liquid without residue and 200kg of sugar residue wet base after solid-liquid separation. Sterilize and cool 1250kg of slag-free saccharification liquid at high temperature, add 20kg of lactic acid producing bacteria, and make 1265kg of anaerobic fermentation at 48-52°C and add calcium hydroxide or calcium carbonate to keep the pH at 5.0-7.0 after 42 hours Calcium lactate fermentation broth containing bacteria. When the temperature of the calcium lactate fermented liquid containing the bacteria is raised to 75-80° C., 60 kg of bacteria acid residue wet base and 1200 kg of calcium lactate dilute solution are obtained through solid-liquid separation. Add 70kg of ferrous sulfate to th...

Embodiment 2

[0079] A preparation method for feeding ferrous lactate, comprising the following steps:

[0080] Grind 140kg of broken rice and 10kg of corn, add 1050kg of water to adjust the slurry, add 0.15-0.20kg of liquefaction enzyme and glucoamylase to liquefy when the temperature rises to 95°C, and obtain 1200kg of sugar liquid with slag, sterilize and cool at high temperature, and insert 20kg Lactic acid-producing bacteria, at 48-52°C and adding calcium hydroxide or calcium carbonate to keep the pH at 5.0-7.0, anaerobically fermented for 42 hours to obtain 1215kg of calcium lactate fermentation broth containing sugar residue and thalline. When the temperature of the calcium lactate fermented liquid containing sugar slag and thalline is raised to 75-80° C., 35 kg of sugar slag thallus acid slag wet base and 1175 kg of calcium lactate dilute solution are obtained through solid-liquid separation. Add 70kg of ferrous sulfate to the calcium lactate dilute solution, and react for 50 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com