Tumor targeted lipidosome drug-delivering system, preparation method and application

A drug delivery system and tumor targeting technology, applied in the field of polypeptide-modified active targeting liposome drug delivery system, can solve the problems of limited application, cytotoxicity, system stability reduction, etc., achieve good curative effect, prolong median effect of survival

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

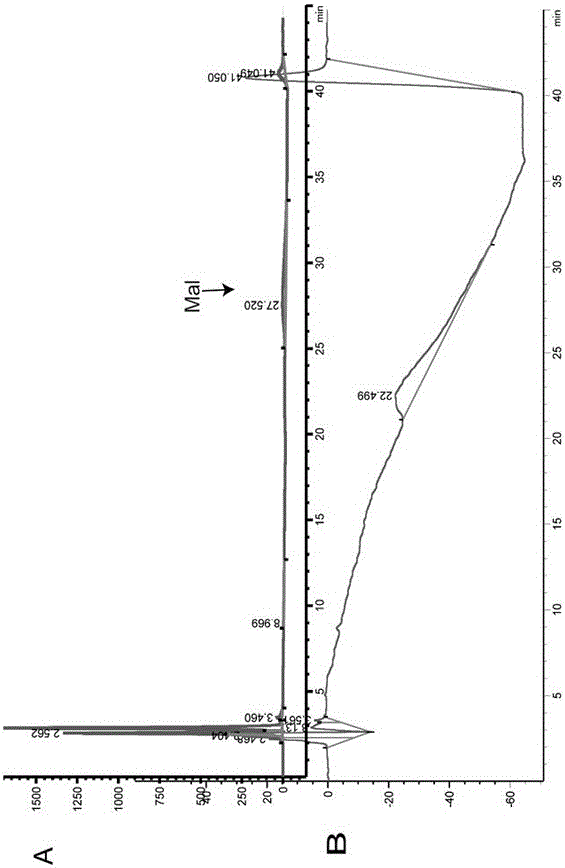

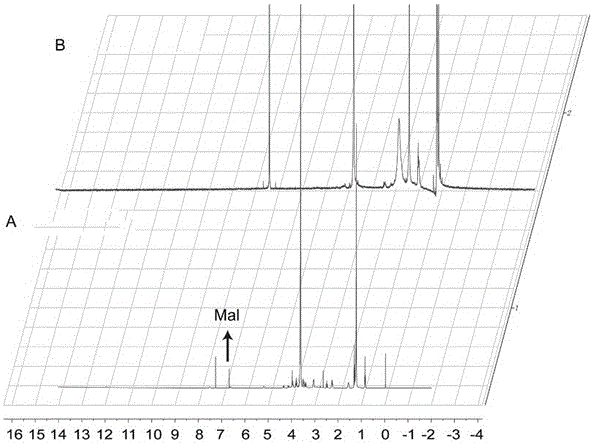

[0033] Synthesis, Purification and Characterization of CRNGRGPDC--PEG--DSPE

[0034] Dissolve CRNGRGPDC in PBS solution (pH7.4), dissolve maleimide-polyethylene glycol-phospholipid complex (Mal-PEG-DSPE) in DMF, mix the two and react with magnetic stirring, high performance liquid phase The reaction was monitored by chromatography (HPLC), and the reaction was stopped after the Mal-PEG-DSPE reaction was complete, and excess CRNGRGPDC and DMF were removed by dialysis (molecular weight cut-off 3.5kDa). After lyophilization, CRNGRGPDC-PEG-DSPE was obtained, and its structure was characterized by HPLC. The HPLC collection of illustrative plates shows that A figure is the HPLC collection of collection of Mal-PEG-DSPE, and B is the HPLC collection of collection of CRNGRGPDC-PEG-DSPE, and main peak retention time is by figure 2 The 27min of the picture A in the middle moves to about 20min of the picture B; the NMR spectrum shows that A is the NMR spectrum of Mal-PEG-DSPE, and B is the...

Embodiment 2

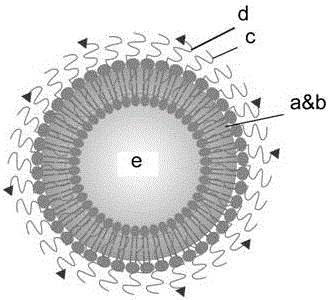

[0036] Preparation and Characterization of CRNGRGPDC--Liposome / DOX

[0037] The liposome composition is HSPC (hydrogenated soybean phospholipid) / Chol (cholesterol) / mPEG-DSPE (polyethylene glycol-distearoylphosphatidylethanolamine complex) (56:44:2, mol / mol), modified by CRNGRGPDC The PEG liposome membrane material formulation is HSPC / Chol / mPEG-DSPE / CRNGRGPDC-PEG-DSPE (56:44:2:1, mol / mol). The above-mentioned membrane material was weighed and dissolved in 1-4ml chloroform (analytical pure), and the organic solvent was removed by rotary evaporation under reduced pressure to obtain a uniform lipid membrane, which was dried in vacuum for 24 hours. Add ammonium sulfate aqueous solution for hydration, and shake in a water bath at 60°C for 2 hours to obtain a liposome suspension. In a water bath at 60°C, use a high-pressure homogenizer (if the liposome volume is less than 10 mL, use a micro extruder) to sequentially squeeze the liposomes through 400, 200, 100 and 50 nm nuclear pore ...

Embodiment 3

[0039] CRNGRGPDC--Preparation and Characterization of Liposome / FAM

[0040] The liposome formulation is composed of HSPC (hydrogenated soybean lecithin) / Chol (cholesterol) / mPEG-DSPE (polyethylene glycol-distearoylphosphatidylethanolamine complex) (56:44:2, mol / mol), CRNGRGPDC The modified PEG liposome membrane material was formulated as HSPC / Chol / mPEG-DSPE / CRNGRGPDC-PEG-DSPE (56:44:2:1, mol / mol). The above-mentioned membrane material was weighed and dissolved in 1-4ml chloroform (analytical pure), and the organic solvent was removed by rotary evaporation under reduced pressure to obtain a uniform lipid membrane, which was dried in vacuum for 24 hours. Add FAM aqueous solution for hydration, and shake in a water bath at 60°C for 2 hours to obtain a liposome suspension. In a water bath at 60°C, use a high-pressure homogenizer (if the liposome volume is less than 10 mL, use a micro extruder) to sequentially squeeze the liposomes through 400, 200, 100 and 50 nm nuclear pore membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com