Novel cement kiln semi-dry desulfurization system

A semi-dry desulfurization and cement kiln technology, applied in the field of desulfurization systems, can solve the problems of low desulfurization efficiency, high ammonia escape, and difficulty in meeting emission standards, and achieve the effect of reducing investment costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

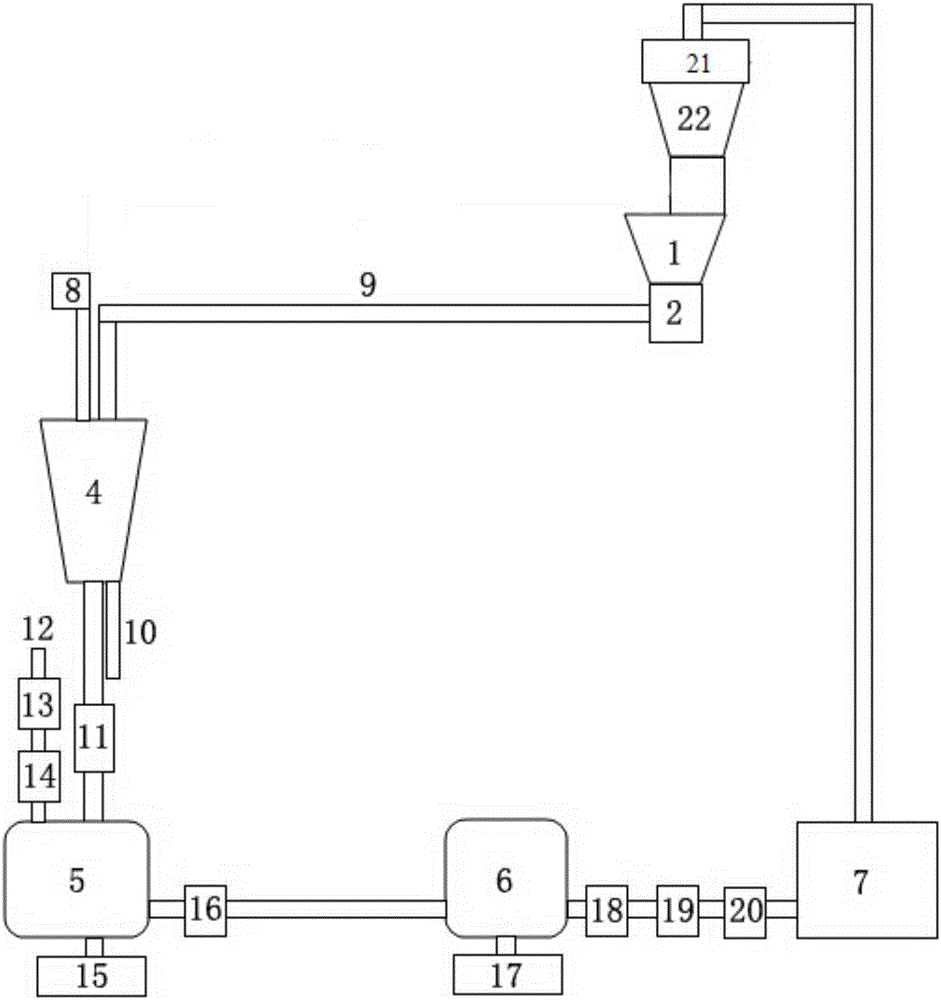

[0023] like figure 1 As shown, a novel cement kiln semi-dry desulfurization system of the present invention includes No. 1 cement kiln cyclone 22 and No. 2 cement kiln cyclone 1, which are arranged vertically in sequence and connected together through pipelines. The bottom of the kiln cyclone 1 is provided with a feeding pipe 2, and the lower part of the feeding pipe 2 is connected with a raw material bin 4, a lime slurry wet digester 5, a lime slurry storage tank 6, and a slaked lime water atomization injection system in turn through a pipeline 9 7. The end of the slaked lime water atomization injection system 7 is connected to the preheater 21 arranged on the upper part of the No. 1 cement kiln cyclone 22 through the pipeline 9 .

[0024] An air pump 3 is arranged on the pipeline 9 between the feeding pipe 2 and the raw material bin 4 .

[0025] The upper part of the raw material bin 4 is provided with a dust collector 8, the bottom side of the raw material bin 4 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com