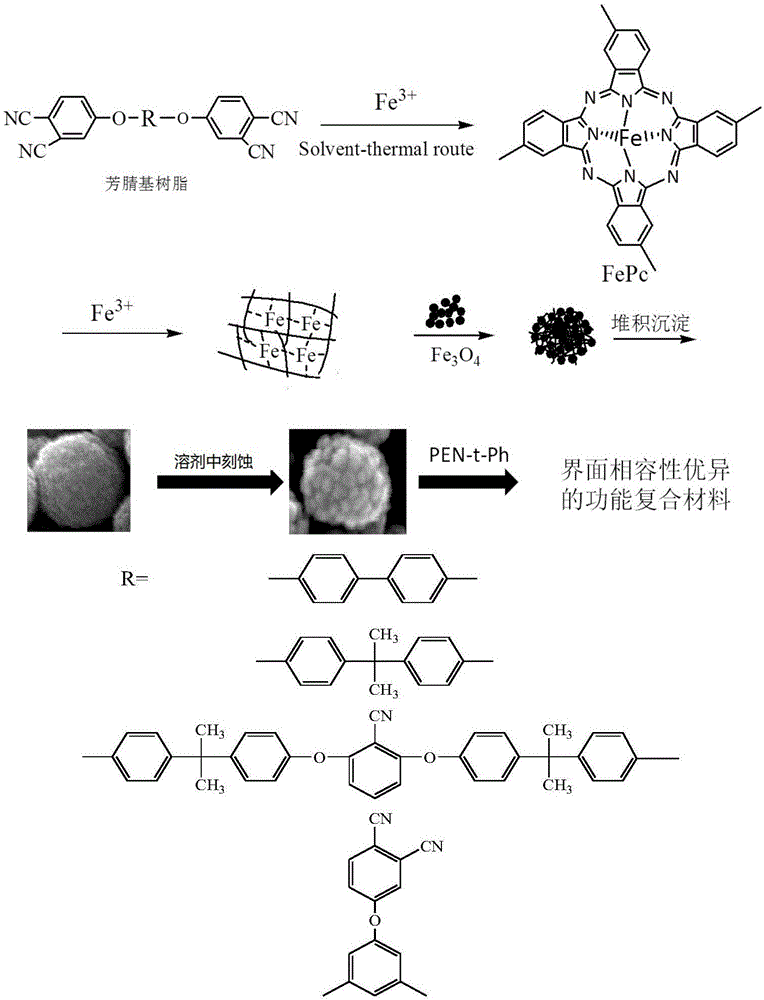

Preparation of surface roughened magnetic nano-microspheres and composite materials thereof

A magnetic nanometer and nanometer microsphere technology, applied in the field of nanomaterials, can solve the problems of composite material performance influence, poor interface compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1. Weigh 6.75g FeCl 3 ·6H 2 O was dissolved in 200mL of ethylene glycol, 1.0g of biphenol type bisphthalonitrile resin (BPh) was dissolved in 3mL of NMP and added to the ethylene glycol solution, then 5.0g of polyethylene glycol 2000 was added, After stirring for 30 minutes, slowly add 18 g of crystalline sodium acetate, and react for 1 hour at normal temperature and pressure;

[0026] Step 2. Transfer the above reaction solution to a polytetrafluoro autoclave, the filling amount of the precursor solution is 80%, and react at 200°C for 15 hours;

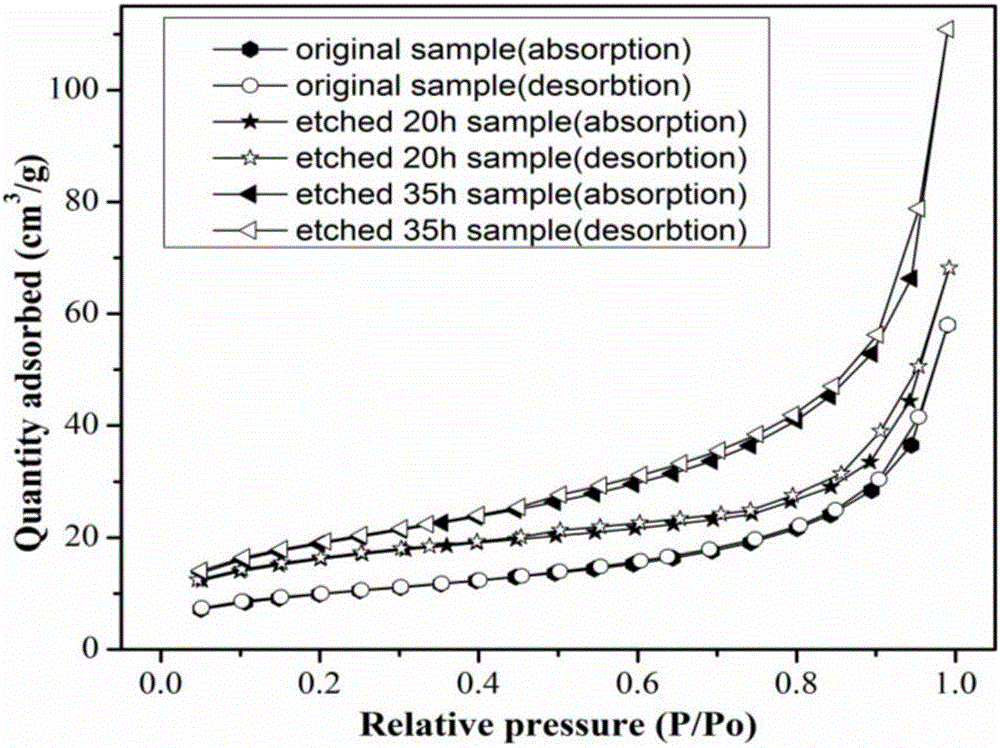

[0027] Step 3. Wash the nanospheres prepared in step 2 with deionized water and ethanol for 2-3 times, then transfer them to 100mL NMP, and react at 80°C for 30h;

[0028] Step 4, the suspension obtained in Step 3 is subjected to solid-liquid separation, and then the solid component is washed 3-4 times with deionized water, and finally dried in a freeze dryer;

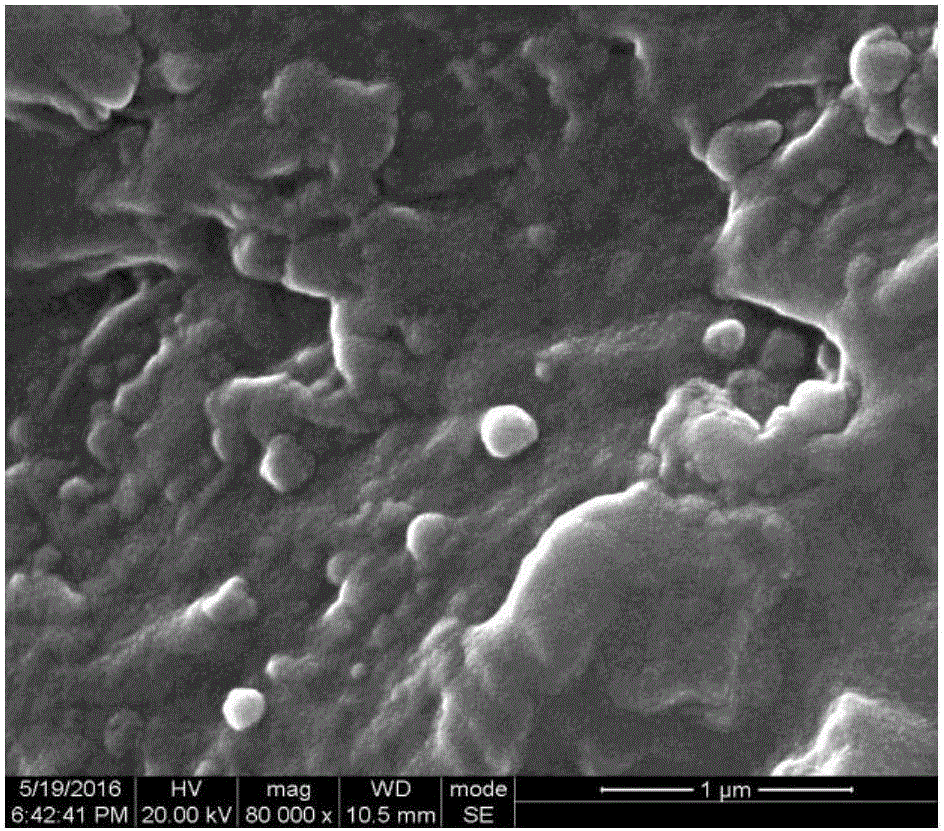

[0029] Step 5. Add 0.1 g of the microspheres obtained in ...

Embodiment 2

[0033] Step 1. Weigh 11.2g FeCl 3 ·6H 2 O was dissolved in 200mL ethylene glycol, 3.5g trifunctional phthalonitrile resin (TPh) was dissolved in 5mL NMP and added to the ethylene glycol solution, then 5.6g polyethylene glycol 2000 was added, and stirred for 30min Slowly add 31.2g of crystalline sodium acetate, and react for 1h at normal temperature and pressure;

[0034] Step 2. Transfer the above reaction solution to a polytetrafluoro autoclave, the filling amount of the precursor solution is 80%, and react at 200°C for 15 hours;

[0035] Step 3. Wash the nanospheres prepared in Step 2 with deionized water and ethanol for 2-3 times, then transfer them to 100 mL of NMP, and react at 80° C. for 30 h;

[0036] Step 4, the suspension obtained in Step 3 is subjected to solid-liquid separation, and then the solid component is washed 3-4 times with deionized water, and finally dried in a freeze dryer;

[0037]Step 5. Add 0.06g of microspheres obtained in step 4 into 6mL NMP, and ...

Embodiment 3

[0041] Step 1. Weigh 7.3g FeCl 3 ·6H 2 O was dissolved in 160mL of ethylene glycol, 2.0g of phthalonitrile resin (2PEN-Ph) containing bisphenol A ether nitrile chain segment was dissolved in 3mL of NMP and added to the ethylene glycol solution, and then 5.4g of poly Ethylene glycol 2000, after stirring for 30 minutes, slowly add 24.48 g of crystalline sodium acetate, and react for 1 hour at normal temperature and pressure;

[0042] Step 2. Transfer the above reaction solution to a polytetrafluoro autoclave, the filling amount of the precursor solution is 80%, and react at 200° C. for 12 hours;

[0043] Step 3. Wash the nanospheres prepared in Step 2 with deionized water and ethanol for 2-3 times, then transfer them to 100 mL of NMP, and react at 80° C. for 30 h;

[0044] Step 4, the suspension obtained in Step 3 is subjected to solid-liquid separation, and then the solid component is washed 3-4 times with deionized water, and finally dried in a freeze dryer;

[0045] Step 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com