Mercury-free catalyst with high catalytic activity for synthesizing vinyl chloride and preparation method thereof

A catalytic activity, mercury catalyst technology, applied in the direction of hydrogen halide addition preparation, chemical instruments and methods, catalytic reactions, etc., can solve the problems of low catalytic activity, low vinyl chloride yield, short service life, etc., and achieve high catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 A kind of preparation method of mercury-free catalyst for the synthesis of vinyl chloride with high catalytic activity

[0039] Include the following steps:

[0040] (1) Selection of carrier

[0041] Using activated carbon as a carrier, the activated carbon has an iodine value of 1223mg / g, a methylene blue value of 114mg / g, an adsorption value of carbon tetrachloride of 124%, a moisture content of 2%, ash content of 1.6%, a mechanical strength of 97.9%, and a bulk density of 398g / L , The specific surface area is 1421m 2 / g, the average pore size is 4.2-4.5nm, and the average particle size of the carrier is 55μm.

[0042] (2) Handling of the carrier

[0043] Prepare 500 kg of hydrochloric acid solution with a mass fraction of 2.2% with high-purity hydrochloric acid and desalinated water, place it at room temperature, and set aside;

[0044] Put 100 kg of selected activated carbon into the above hydrochloric acid solution and soak for 100 minutes. During ...

Embodiment 2

[0072] Example 2 Application of a mercury-free catalyst with high catalytic activity in the synthesis reaction of vinyl chloride

[0073] Include the following steps:

[0074] (1) Loading catalyst catalyst

[0075] Before loading the catalyst catalyst, check that there are no leaks inside and outside the reactor, and the inner wall of the tubes is clean, dry, and free of debris; the catalyst of the present invention is immediately packed into each tube of the reactor after opening the package, and the catalyst should be loaded within 0.5h Finish inside, beware of moisture.

[0076] (2) Preheating

[0077] Inject dry HCl at 90-100°C, and control the rate at 7m 3 / h, continuously for 12 hours, during which acid is released from the bottom of the reactor every 2 hours.

[0078] (3) Synthesis of vinyl chloride reaction

[0079] The molar ratio of acetylene and hydrogen chloride is controlled at 1:0.92 (100% purity), and the mixed gas with a preheated temperature above 90°C is...

Embodiment 3

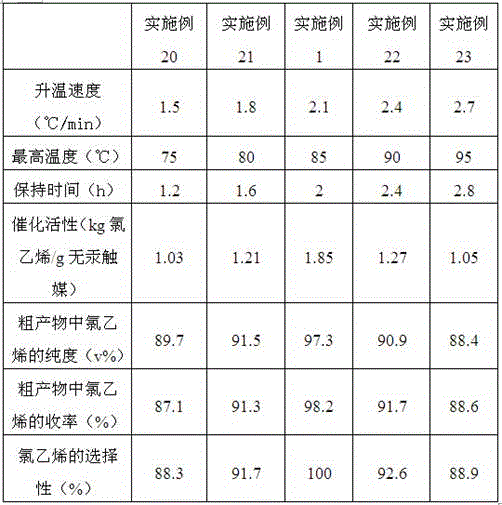

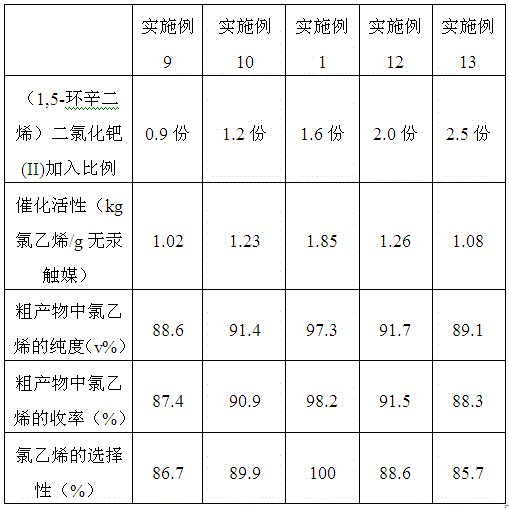

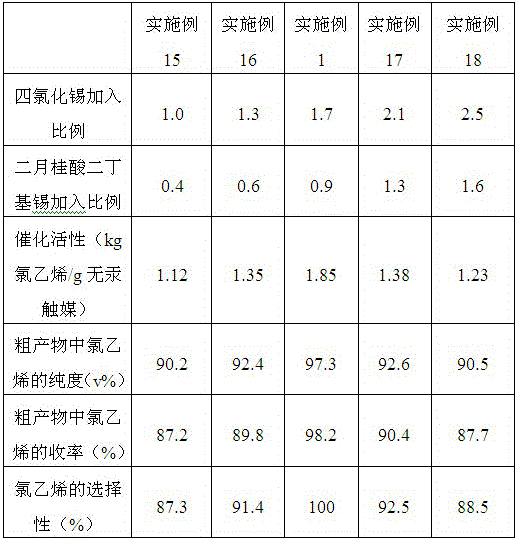

[0085] The screening of copper compound in the catalyst component of embodiment 3

[0086] Adopt the preparation method of mercury-free catalyst described in Example 1, only change the type of copper compound in the selection of catalyst raw materials in step (3), and change the solvent for dissolving the corresponding copper compound in step (5) at the same time to ensure the corresponding copper compound Dissolve fully, carry out single factor analysis experiment, will prepare mercury-free catalyst, adopt the application method described in embodiment 2 to carry out experiment, experimental result is shown in Table 1.

[0087] The screening of copper compound in the catalyst component of table 1

[0088]

[0089] Through the above-mentioned single factor analysis experiment, it can be seen that Embodiment 1 is a preferred embodiment, that is, the copper compound in the catalyst component is preferably chlorinated ketone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com