Ocean pile driving barge

A piling ship and marine technology, applied in the field of ships, can solve the problems of difficult to meet the rapid growth of coastal infrastructure construction projects, do not meet the requirements of energy conservation and environmental protection, and the overall technical level is not high, so as to improve environmental protection and operating economy, The effect of optimizing the configuration of electromechanical equipment and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to better understand the present invention, the present invention is described in detail below in conjunction with specific examples. It will, however, be evident that various changes and modifications can be made to the present invention without departing from the broader spirit and scope of the invention as defined in the appended claims. Therefore, the following examples have an illustrative rather than a limiting meaning.

[0046] Example:

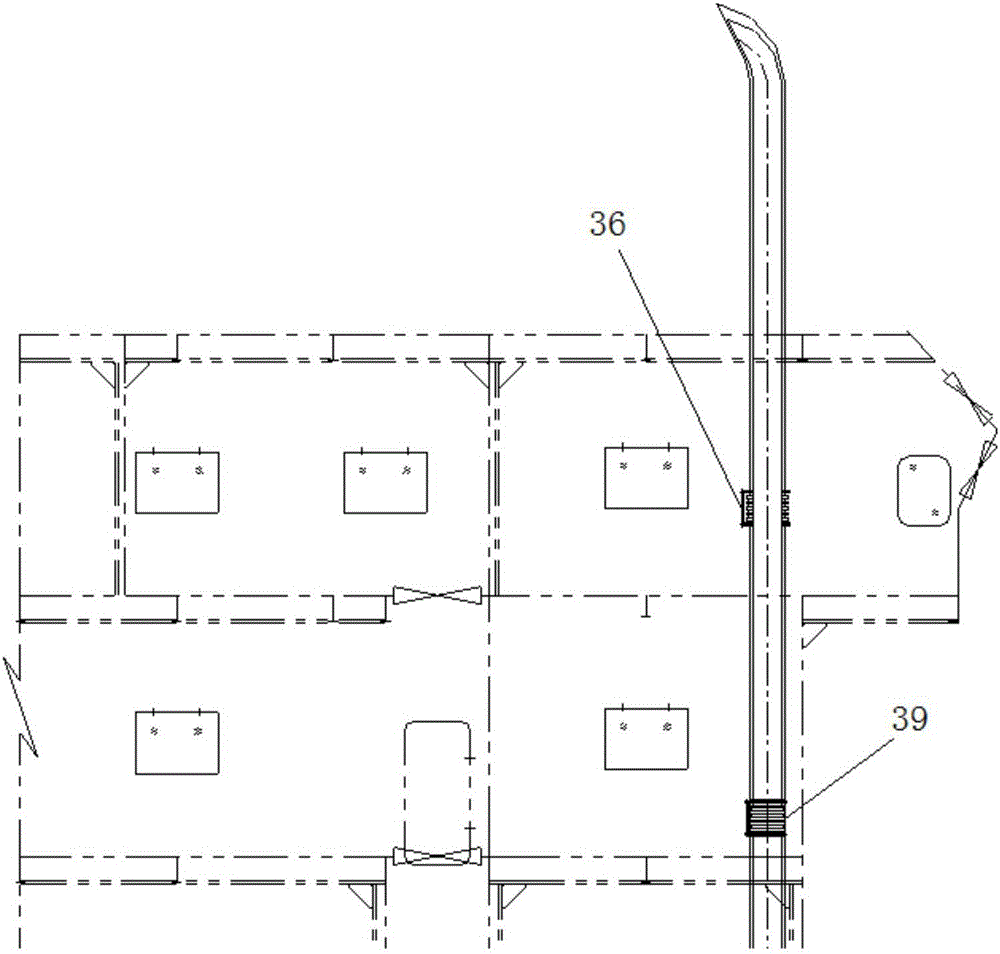

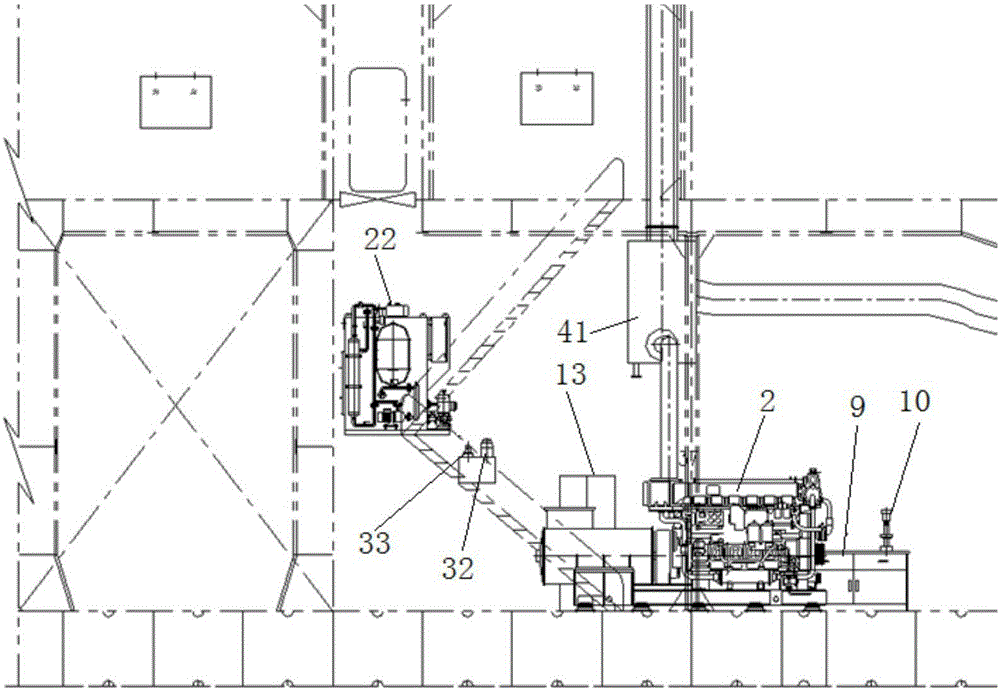

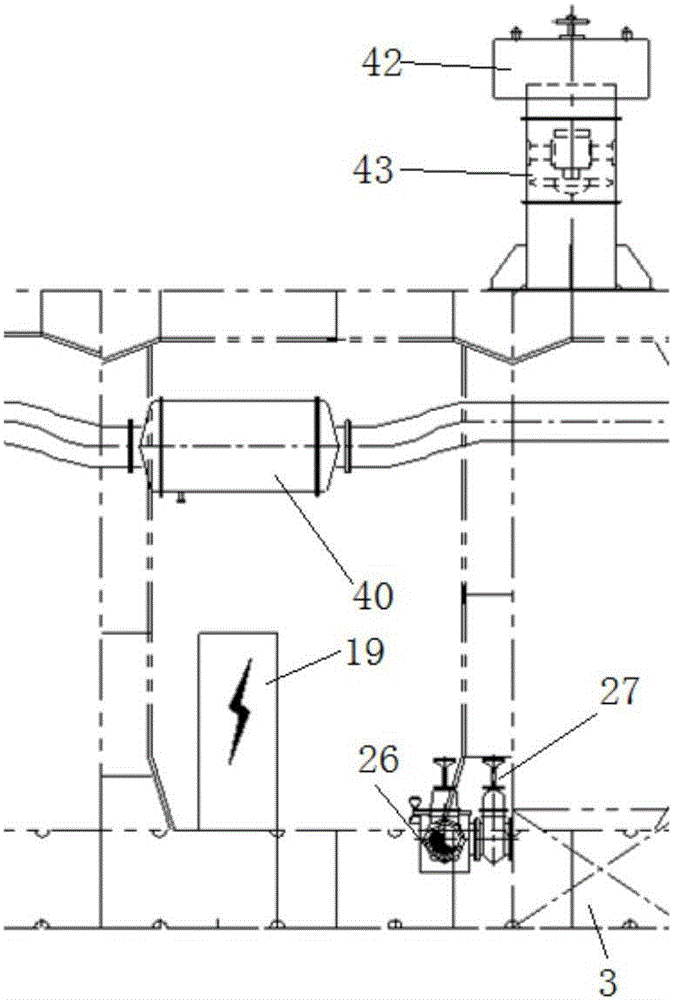

[0047] A marine piling vessel such as Figure 1 to Figure 27 As shown, including the hull and the pile frame, the hull is provided with a first oil pump diesel engine 1, an auxiliary generator set 2, a seawater tank 3, a second oil pump diesel engine 4, an output oil pump transfer gearbox 5, a sewage oil hand pump 6, a portable Type air foam gun 7, oil and sewage separation device 8, workbench 9, bench drill 10, vise 11, grinder 12, tool box 13, miscellaneous air bottle 14, air compressor 15, third oil pump diesel eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com