Method for preparing single-walled carbon nanotubes in oriented arrangement with solution standing method

A technology of single-wall carbon nanotubes and directional arrangement, applied in nanotechnology, nanotechnology, nanostructure manipulation, etc., can solve the problems of low concentration of carbon nanotubes, high cost of carbon nanotubes, and lack of orientation, and achieve equipment Low requirements, stable electrical performance, and good orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

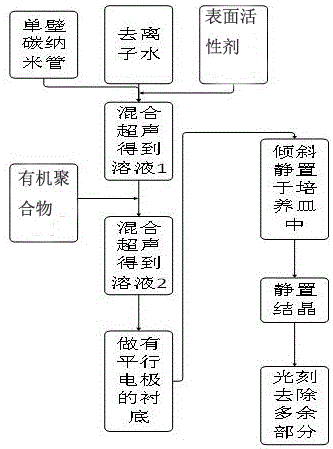

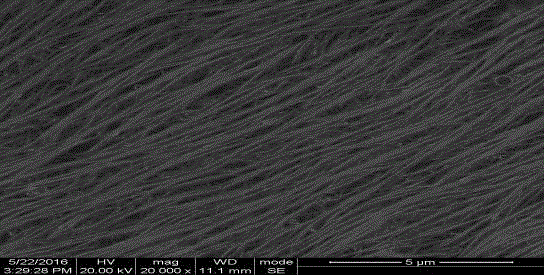

[0034] Embodiment 1: A kind of method for preparing single-walled carbon nanotubes of oriented arrangement by solution static method, comprises the following steps:

[0035] (1) Take 20 mL of deionized water and put it into a beaker, weigh 15 mg of carbon nanotubes, weigh 100 mg of sodium dodecylbenzenesulfonate and add it to the beaker, put a magnetic rotor in the beaker, put the beaker into a magnetic stirrer, Adjust the temperature to 70°C, the rotational speed to 12rad / s, magnetically stir for 3 hours, and perform ultrasonic mixing at the same time, so that sodium dodecylbenzenesulfonate and carbon nanotubes are uniformly dispersed in deionized water to obtain solution 1;

[0036] (2) Take 150 mg of polyvinylpyrrolidone and add it to solution 1, adjust the temperature to 70°C, rotate at 12 rad / s, stir magnetically for 10 minutes, and perform ultrasonic mixing at the same time to obtain a black colloidal liquid, namely solution 2;

[0037] (3) The wet film was prepared by t...

Embodiment 2

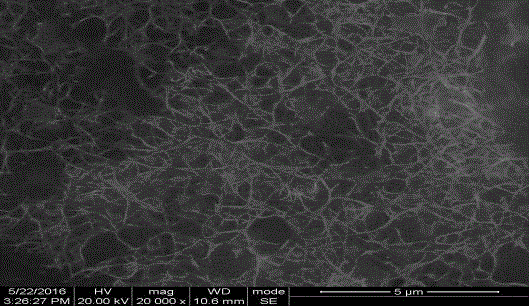

[0040] Embodiment 2: A kind of method for preparing single-walled carbon nanotubes of oriented arrangement by static method of solution, comprises the following steps:

[0041] (1) Take 20 mL of deionized water and put it into a beaker, weigh 15 mg of carbon nanotubes, weigh 75 mg of dodecyltrimethylammonium bromide, and add 75 mg of hexadecyltrimethylammonium bromide into the beaker, and ultrasonically Mix to make dodecyltrimethylammonium bromide, cetyltrimethylammonium bromide and carbon nanotubes uniformly dispersed in deionized water to obtain solution 1;

[0042] (2) Add 150mg of polystyrene sulfonate and 150mg of polyvinyl alcohol into solution 1, and mix them uniformly with ultrasound to obtain a black colloidal liquid, namely solution 2;

[0043] (3) The wet film was prepared by the solution static method, and the substrate with parallel electrodes was placed in the solution 2 at an angle of 2° to prepare a wet film, and it was crystallized after standing for 72 hours;...

Embodiment 3

[0045] Embodiment 3: A kind of method for preparing single-walled carbon nanotubes of oriented arrangement by solution static method, comprises the following steps:

[0046](1) Take 20 mL of deionized water and put it into a beaker, weigh 15 mg of carbon nanotubes, weigh 40 mg of cetyltrimethylammonium bromide, and add 60 mg of sodium dodecylbenzenesulfonate into the beaker. Insert the magnetic rotor, put the beaker into a magnetic stirrer, adjust the temperature to 80°C, and the rotation speed to 12rad / s, and magnetically stir for 5 hours, while ultrasonically mixing, so that sodium dodecylbenzenesulfonate and carbon nanotubes are evenly dispersed in the In deionized water, solution 1 was obtained;

[0047] (2) Take 200 mg of polyvinyl alcohol and add it to solution 1, adjust the temperature to 80 ° C, rotate at 12 rad / s, stir magnetically for 20 minutes, and perform ultrasonic mixing at the same time to obtain a black colloidal liquid, namely solution 2;

[0048] (3) The we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com