Intelligent polymer composite, preparation method and application of intelligent polymer composite

A technology of smart polymers and composite materials, which is applied in the field of self-repair of composite materials, can solve the problems of no light stimulus response and achieve the effect of enhancing the strength of polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

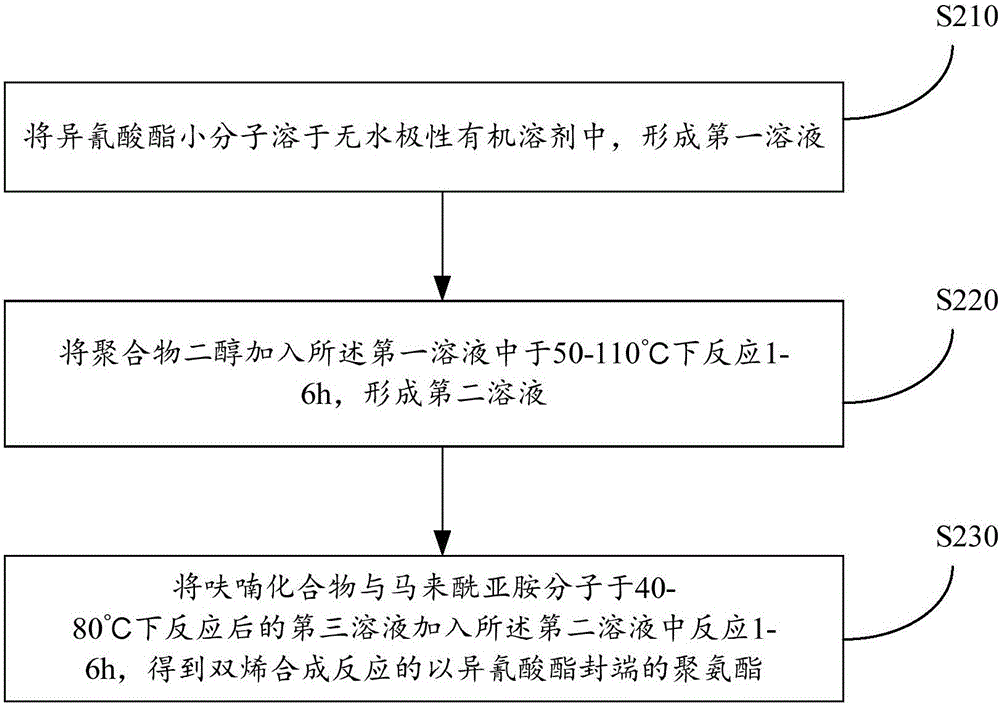

[0034] A method for preparing an intelligent polymer composite material, comprising the following steps: uniformly dispersing functionalized graphene in an anhydrous polar organic solvent, adding polyurethane, and reacting for 4-10 hours at a temperature of 50-100°C to obtain The intelligent polymer composite material; wherein, the polyurethane is isocyanate-terminated polyurethane with diene synthesis reaction.

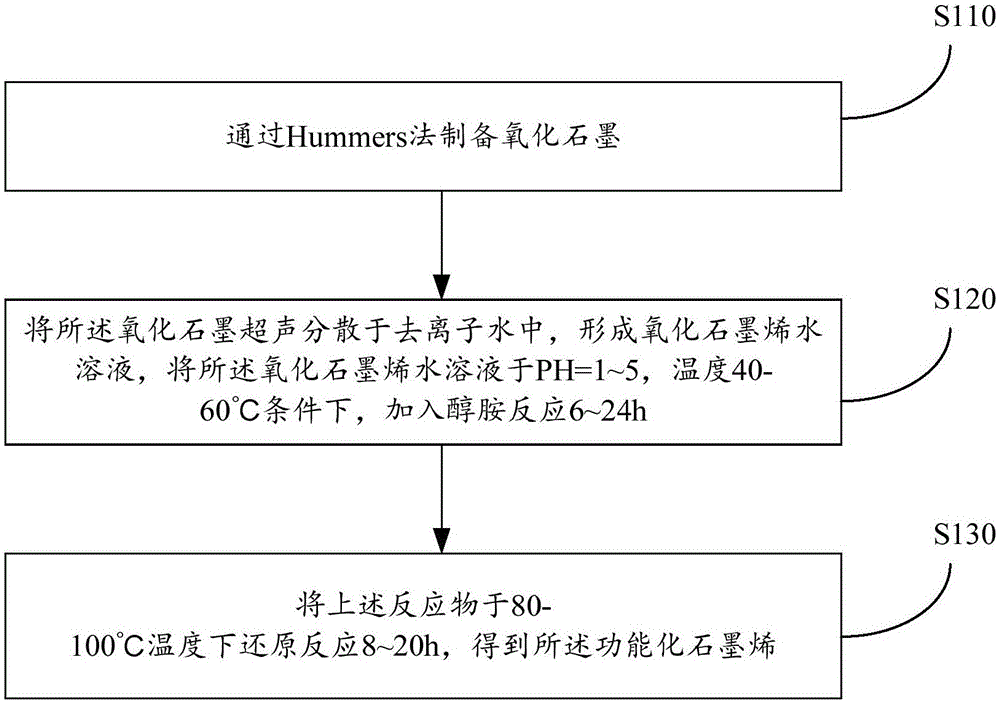

[0035] Preferably, see figure 1 , the functionalized graphene is prepared by the following method:

[0036] Step S110: preparing graphite oxide by the Hummers method;

[0037] Step S120: ultrasonically disperse the graphite oxide in deionized water to form a graphene oxide aqueous solution, and react the graphene oxide aqueous solution with an alcohol amine at a pH of 1-5 and a temperature of 40-60°C for 6-24 hours ;

[0038] Preferably, the concentration of the graphene oxide aqueous solution is 0.2 mg / mL˜10 mg / mL.

[0039] Preferably, the alcoholamine is at lea...

Embodiment 1

[0054] 1g of 4,4'-methylenebis(phenylisocyanate) was dissolved in N,N-dimethylformamide and stirred, adding polytetrahydrofuran, N 2 Atmosphere, react at 80°C for two hours; add the DMF solution of furan methanol and N,N'-(4,4'-methylenediphenyl)bismaleimide to the above solution after pre-reacting at 60°C for 2 hours , react in N2 atmosphere for 2h; finally take 6.1mg of functionalized graphene and add it into the above solution to stir and react for 5h, so as to obtain functionalized graphene / polyurethane composite material. Finally, the obtained mixture was poured into a tetrafluoroethylene mold and dried in a vacuum oven to shape.

[0055] Introduce a wound on the obtained functionalized graphene / polyurethane composite film, and repair it under an infrared laser with a wavelength of 980nm and a power density of 7mW / cm2.

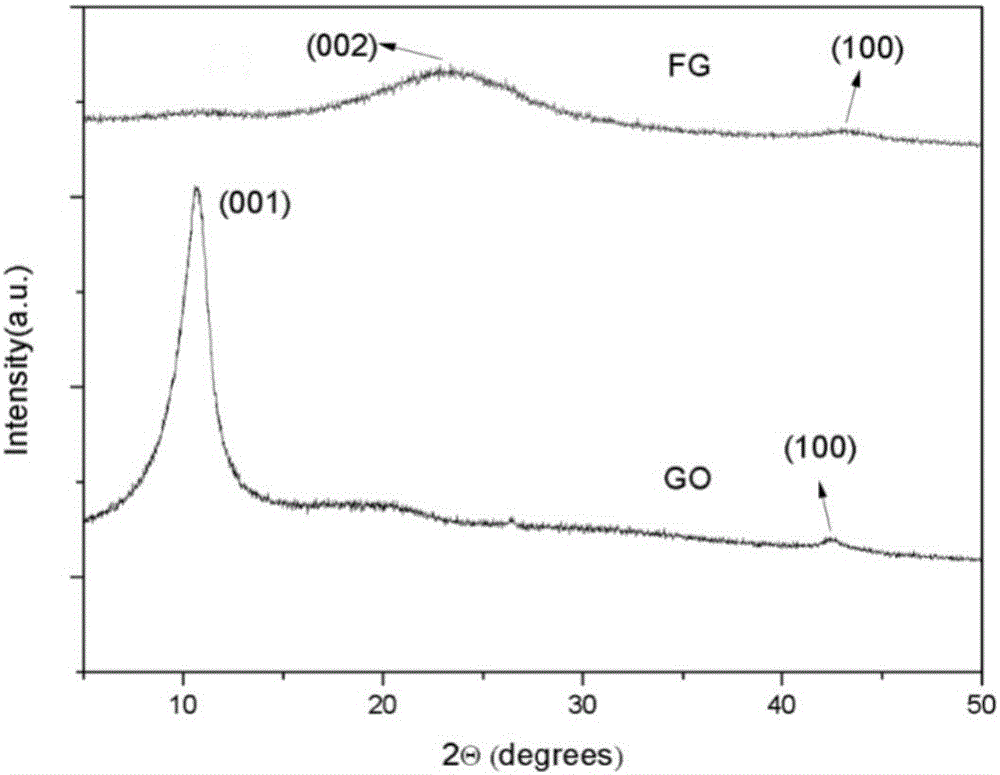

[0056] see image 3 , is the graphene oxide and functionalized graphene XRD contrast figure that embodiment 1 makes; Fig. 6 is the XRD spectrogram of g...

Embodiment 2

[0060] The difference between the preparation method of the smart polymer composite material capable of self-repairing by infrared light in this example and Example 2 lies in that 30.5 mg of functionalized graphene is added and reacted for 5 hours. Other steps are as in Example 1.

[0061] Introduce the wound on the obtained functionalized graphene / polyurethane composite film, and repair it under the infrared light with a wavelength of 980nm and a power density of 6mW / cm2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com