Diesel oil fuel combustion enhancing additive

A technology of additives and diesel oil, which is applied in the direction of fuel additives, fuels, liquid carbon-containing fuels, etc., can solve the problems of not improving the combustion efficiency of diesel oil, reducing the normal operation of internal combustion engines, and the effect is not very satisfactory, so as to protect the engine fuel system , improve the cold start problem, improve the effect of storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

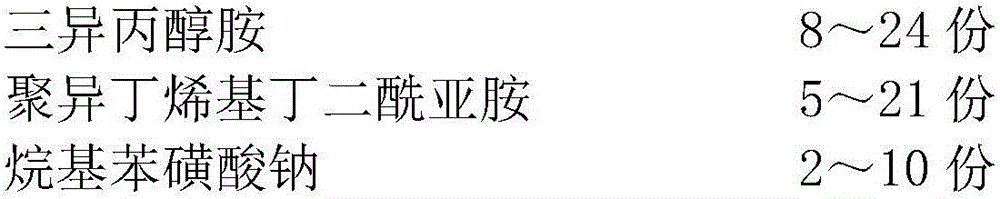

[0025] Diesel fuel combustion-enhancing additive is made of the following raw materials in parts by weight (mixed uniformly at normal temperature):

[0026]

[0027] The diesel fuel combustion enhancing additive of the present invention is used in the preparation of diesel fuel, and the additive accounts for 0.02% of the mass of diesel fuel.

Embodiment 2

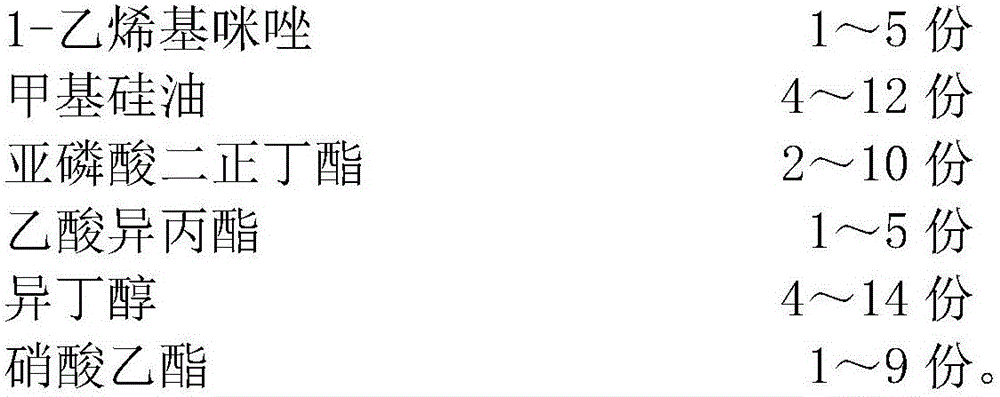

[0029] Diesel fuel combustion-enhancing additive is made of the following raw materials in parts by weight (mixed uniformly at normal temperature):

[0030]

[0031] The diesel fuel combustion enhancing additive of the present invention is used in the preparation of diesel fuel, and the additive accounts for 0.04% of the mass of diesel fuel.

Embodiment 3

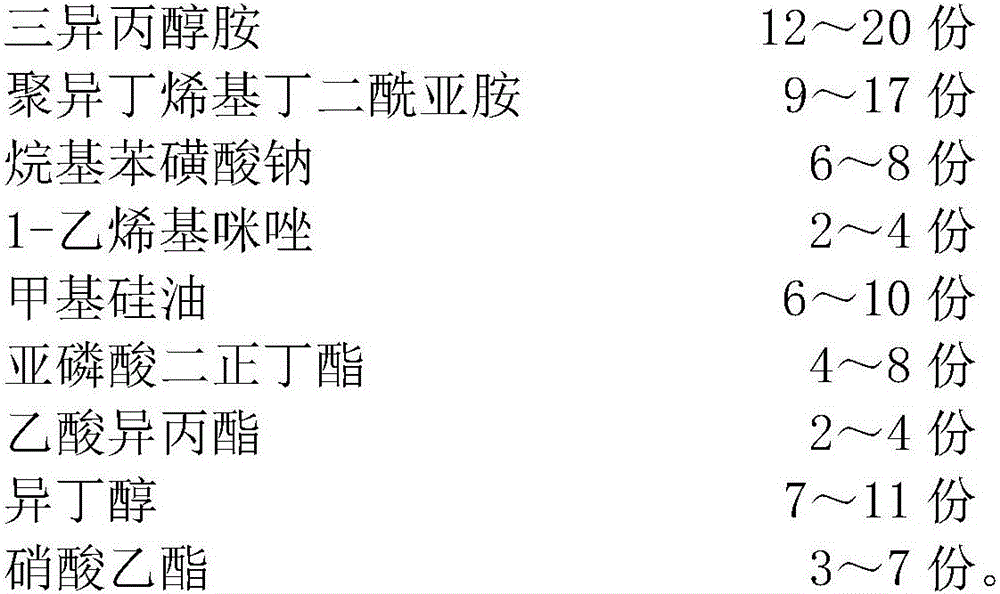

[0033] Diesel fuel combustion-enhancing additive is made of the following raw materials in parts by weight (mixed uniformly at normal temperature):

[0034]

[0035] The diesel fuel combustion enhancing additive of the present invention is used in the preparation of diesel fuel, and the additive accounts for 0.05% of the mass of diesel fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com