A kind of nanoporous Fe-based amorphous alloy and its preparation method and its application on oxygen evolution catalytic electrode

A nanocrystalline alloy and amorphous alloy technology, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve problems that no one has mentioned, and achieve the effect of simple preparation method, good repeatability, and excellent oxygen evolution catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

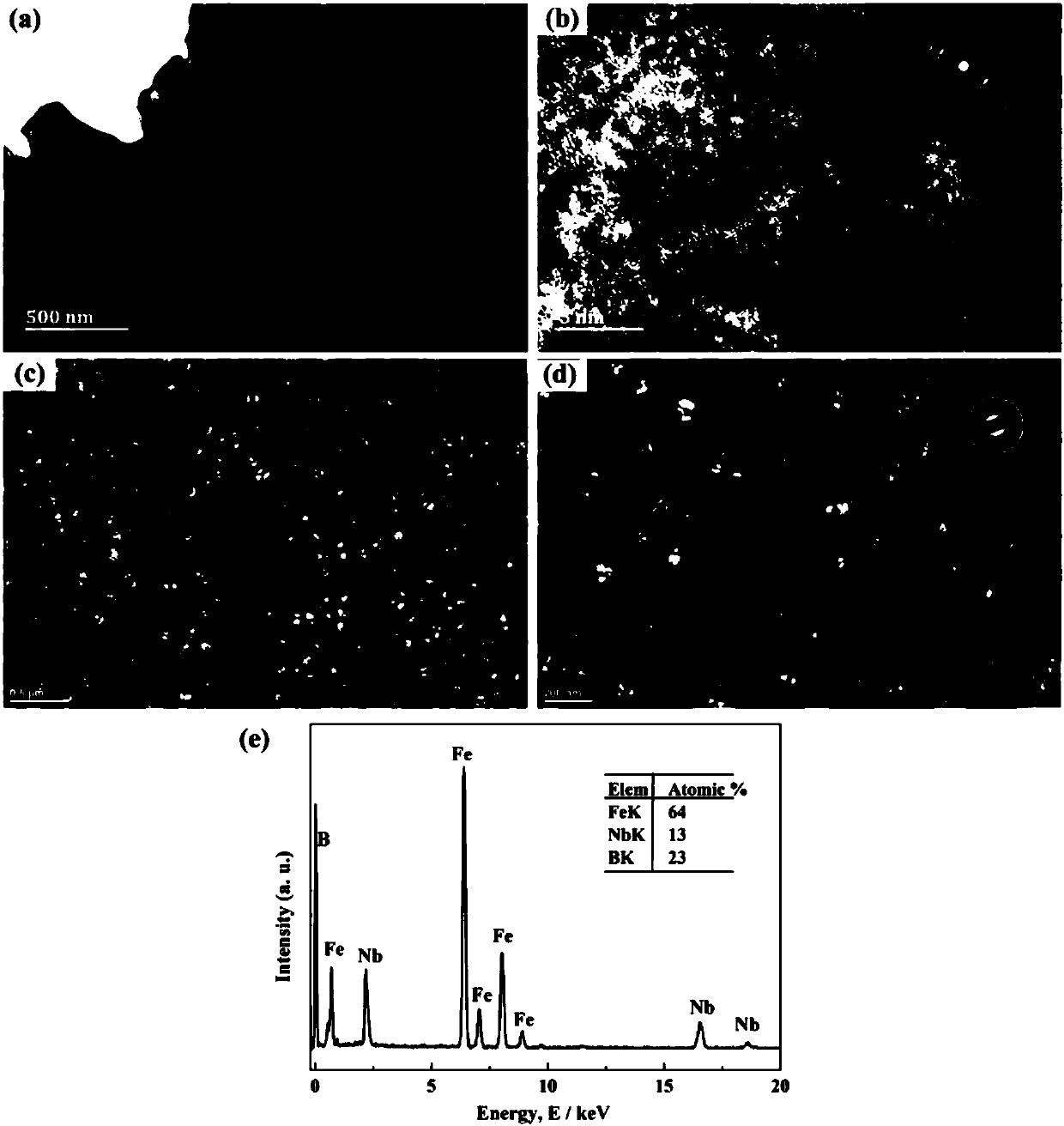

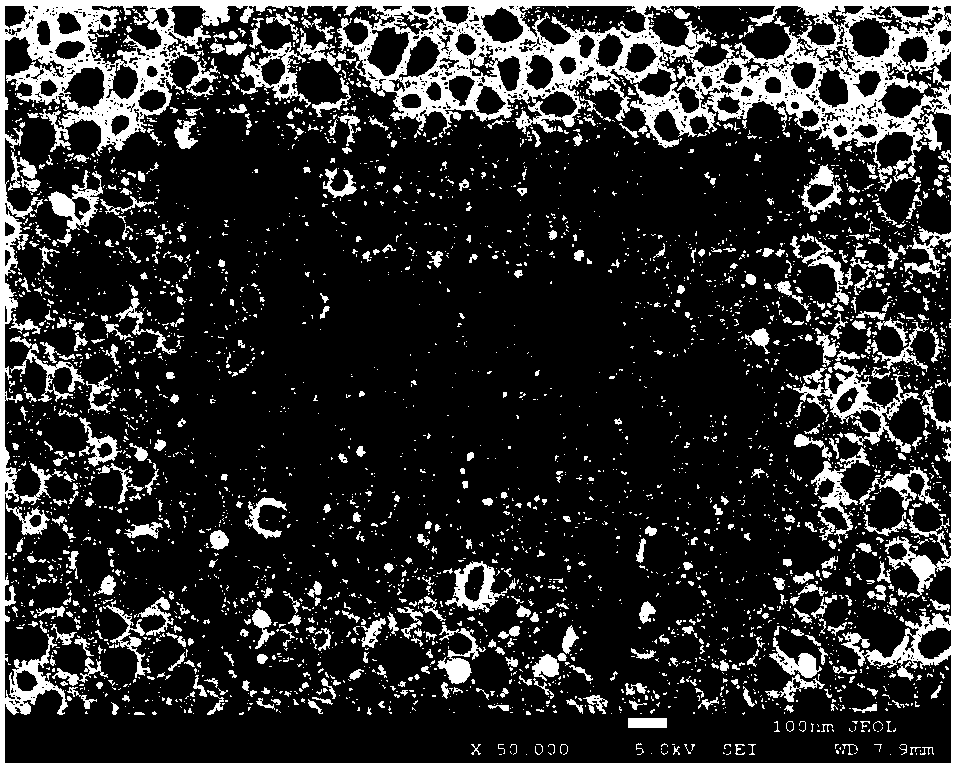

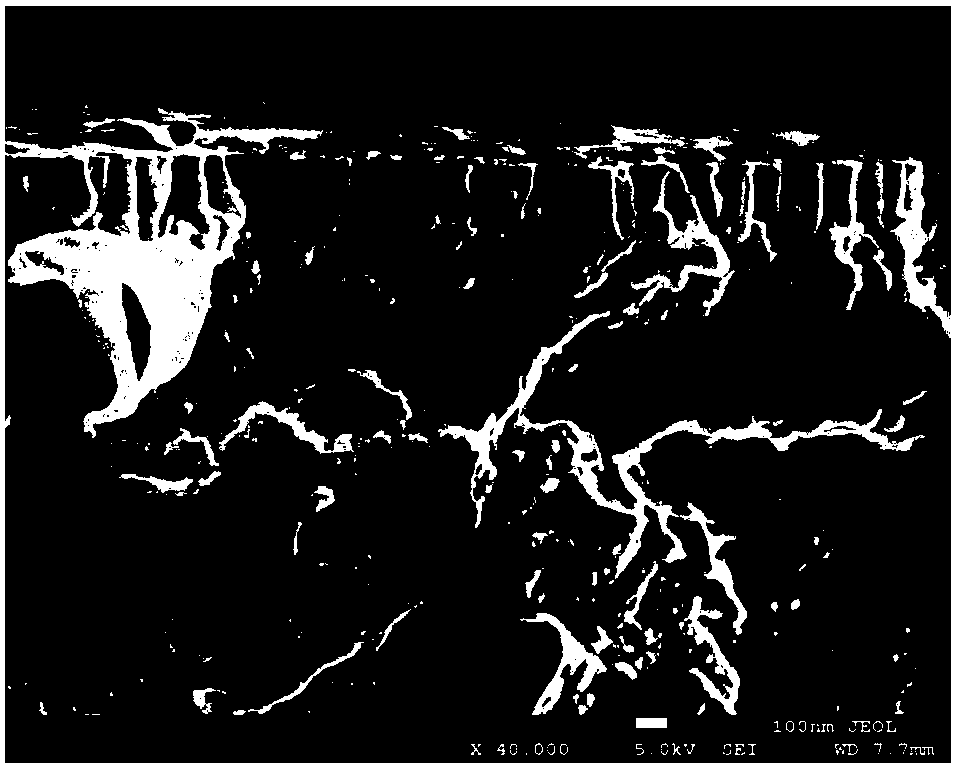

[0052] Embodiment 1: with Fe 82 Nb 6 B 12 Preparation of Nanoporous Fe-based Amorphous Alloys Using Amorphous / Nanocrystalline Alloy Ribbons as Precursors

[0053] In this embodiment, the selected amorphous / nanocrystalline alloy precursor composition is Fe 82 Nb 6 B 12 , the preparation method of nanoporous material is as follows:

[0054] Step 1: Ingredients

[0055] Press Fe 82 Nb 6 B 12 Nominal composition Fe, Nb elemental elements and FeB (B: 21wt%) are pre-alloyed to become raw materials for preparing master alloy ingots;

[0056] Step 2: Melting the master alloy

[0057] Fe, Nb elemental elements and FeB pre-alloyed by Fe 82 Nb 6 B 12 The nominal composition is smelted in a vacuum arc melting furnace and smelted 3-4 times to obtain a master alloy ingot;

[0058] The smelting conditions are: the vacuum degree in the vacuum arc melting furnace during smelting is 8×10 -3 Below Pa, fill it with 0.05Mpa high-purity argon, smelt for 1-2 minutes each time, and sme...

Embodiment 2

[0067] Embodiment 2: with Fe 84 Nb 6 B 9 Cu 1 Preparation of Nanoporous Fe-based Amorphous Alloys Using Amorphous / Nanocrystalline Alloy Ribbons as Precursors

[0068] In this embodiment, the selected amorphous / nanocrystalline alloy precursor composition is Fe 84 Nb 6 B 9 Cu 1 , the preparation method of nanoporous material is as follows:

[0069] Step 1: Ingredients

[0070] Press Fe 84 Nb 6 B 9 Cu 1 Nominal composition Weigh Fe, Nb, Cu elemental elements and FeB (B: 21wt%) pre-alloyed to become the raw material for preparing master alloy ingot;

[0071] Step 2: Melting the master alloy

[0072] Fe, Nb, Cu elemental elements and FeB pre-alloyed by Fe 84 Nb 6 B 9 Cu 1 The nominal composition is smelted in a vacuum arc melting furnace and smelted 3-4 times to obtain a master alloy ingot;

[0073] The smelting conditions are: the vacuum degree in the vacuum arc melting furnace during smelting is 8×10 -3 Below Pa, fill it with 0.05Mpa high-purity argon, smelt fo...

Embodiment 3

[0082] Embodiment 3: with Fe 54 Ni 30 Nb 6 B 9 Cu 1 Preparation of Nanoporous Fe-based Amorphous Alloys Using Amorphous / Nanocrystalline Alloy Ribbons as Precursors

[0083] In this embodiment, the selected amorphous / nanocrystalline alloy precursor composition is Fe 54 Ni 30 Nb 6 B 9 Cu 1 , the preparation method of nanoporous material is as follows:

[0084] Step 1: Ingredients

[0085] Press Fe 54 Ni 30 Nb 6 B 9 Cu 1 Nominal composition Weigh Fe, Ni, Nb, Cu elemental elements and FeB (B: 21wt%) pre-alloyed to become raw materials for preparing master alloy ingots;

[0086] Step 2: Melting the master alloy

[0087] Fe, Ni, Nb, Cu elemental elements and FeB pre-alloyed by Fe 54 Ni 30 Nb 6 B 9 Cu 1 The nominal composition is smelted in a vacuum arc melting furnace and smelted 3-4 times to obtain a master alloy ingot;

[0088] The smelting conditions are: the vacuum degree in the vacuum arc melting furnace during smelting is 8×10 -3 Below Pa, fill it with 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com