Tail gas treatment and discharge mechanism of a sludge dryer

A technology for tail gas treatment and sludge drying, which is applied in chemical instruments and methods, air quality improvement, separation methods, etc. It can solve the problems of shortened service life of microbial filter materials, pollution of filter residue and residual liquid, and impact on gas permeability, etc. problems, to achieve the effect of space saving, strong adsorption capacity, fast and efficient cleaning of filter residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further specifically described below through examples.

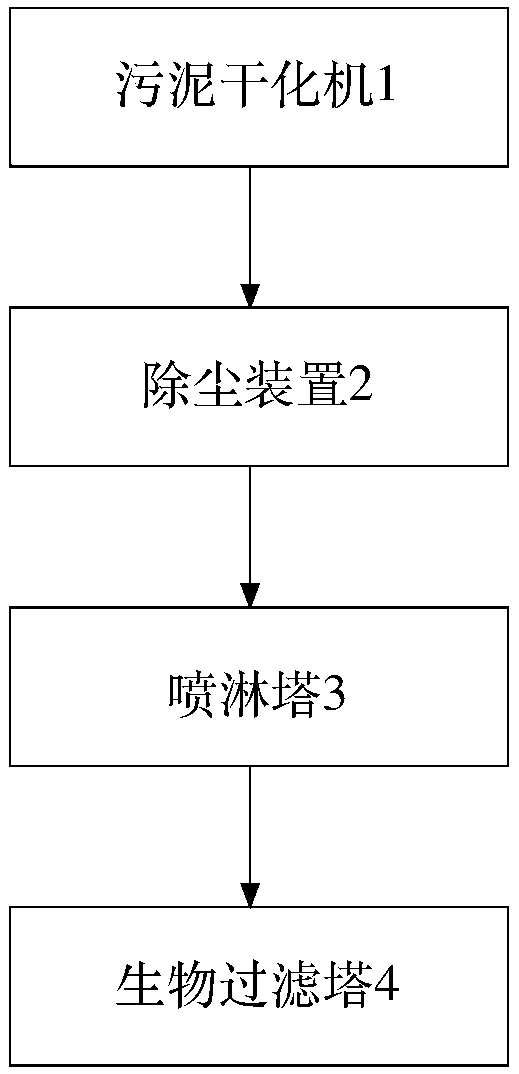

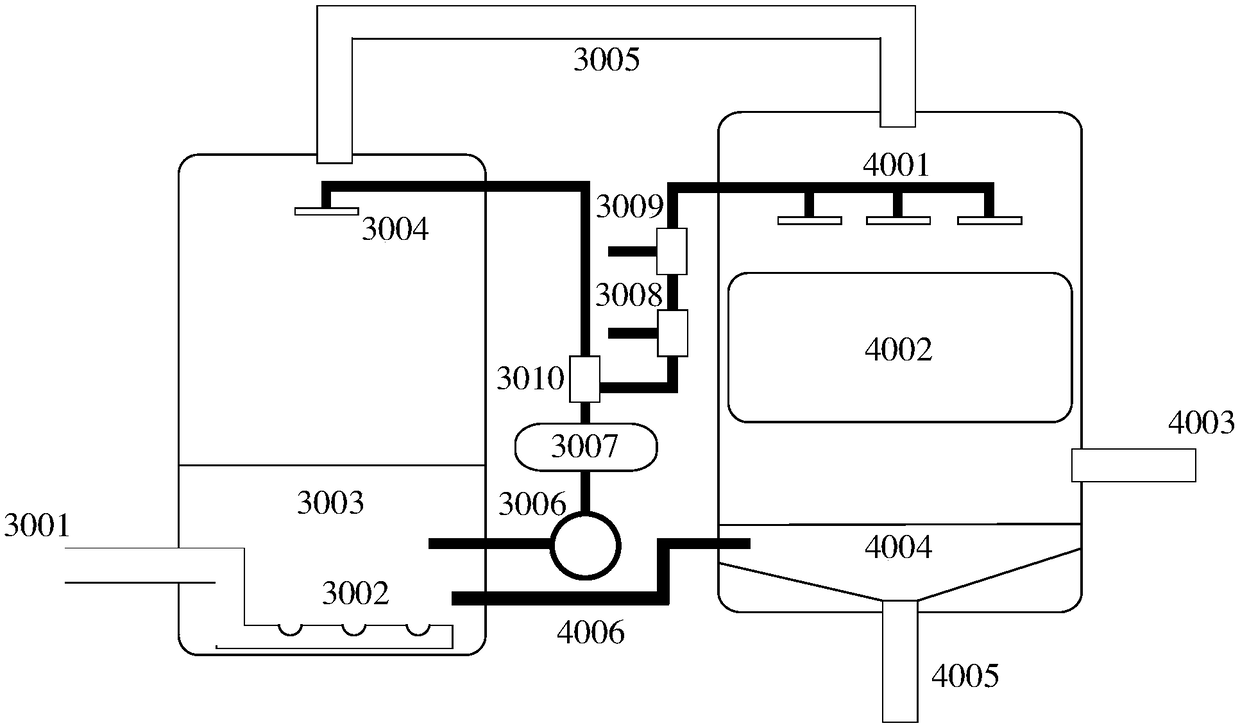

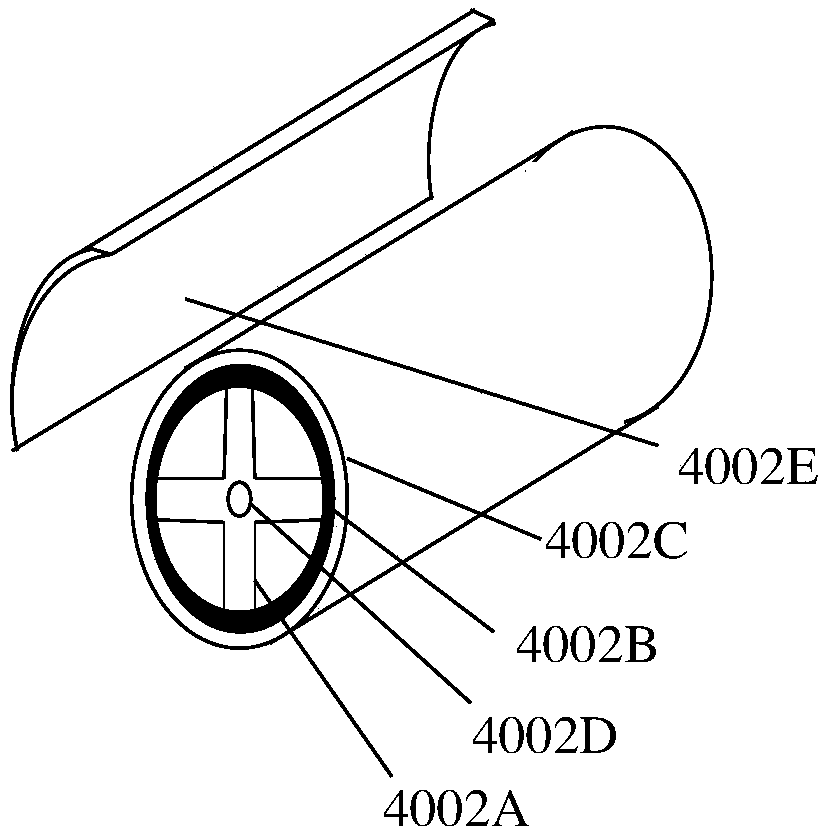

[0026] figure 1 It is a schematic diagram of the overall architecture of the preferred embodiment of the present invention. The water vapor, volatile gas and sludge dust particles generated during the thermal drying and dehydration treatment of the sludge by the sludge dryer 1 are discharged in the form of tail gas. The tail gas enters the tail gas treatment and discharge mechanism of the present invention, which specifically includes a dust removal device 2 , a spray tower 3 and a biological filter tower 4 . The tail gas is sequentially carried out in this mechanism to remove dust, spray to remove inorganic soluble compounds, bio-filter adsorption and decompose organic compounds, so that the dust particles and toxic, harmful and malodorous components in the dry tail gas finally discharged to the atmosphere are basically eliminated. Reach environmental emi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com