Robot special for wave compensation and wave compensation method

A technology of wave compensation and robotics, which is applied in the directions of manipulators, program-controlled manipulators, and equipment for increasing the stability of ships. It can solve the problems of disjoint wrist rotation axes, small movement space, and large overall weight, so as to increase the working space and flexibility. Accurate, achieve overall position adjustment, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

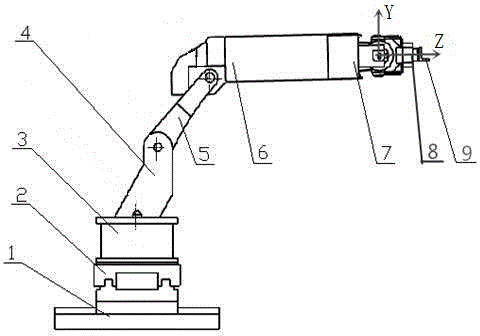

[0023] see figure 1 The bottom of the special robot for wave compensation shown is the adjustment guide rail. The adjustment guide rail is composed of the longitudinal guide rail combination 1 and the horizontal guide rail combination 2. The lower part is the longitudinal guide rail combination 1, and the upper part is the horizontal guide rail 2. The adjustment guide rail passes through the lower longitudinal guide rail combination 1. The bolts are fastened to the deck of the ship. The upper end of the adjustment guide rail is a mechanical arm, and the mechanical arm is mainly composed of a mechanical arm base 3, a large arm 4, a connecting arm 5, and a small arm 6. The mechanical arm base 3 is fixed on the adjustment guide rail by bolts, so that the whole mechanical arm is connected to the adjustment guide rail through the mechanical arm base 3 . A position sensor is installed at the center of the base 3 of the manipulator to detect the roll, pitch and heave of the robot as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com