Material issuing tank utilizing pressure-conveying type high-pressure dense-phase multi-path pneumatic conveying mode and conveying system of material issuing tank

A pneumatic conveying system, a technology of pneumatic conveying, is used in conveying bulk materials, conveyors, transportation and packaging, etc. It can solve problems such as mutual interference, uneven flow, overall flow or single-channel flow is not smooth, and achieve simplified structure, The effect of reducing the difficulty of rolling and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the accompanying drawings.

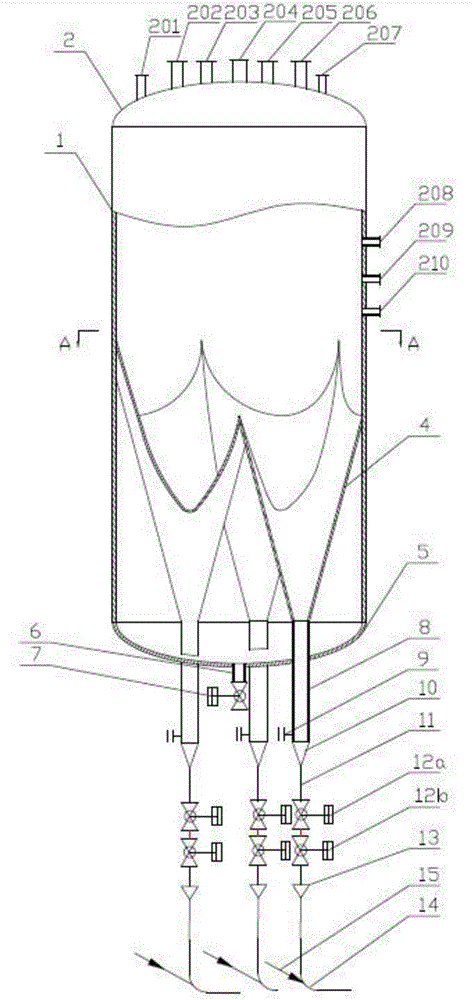

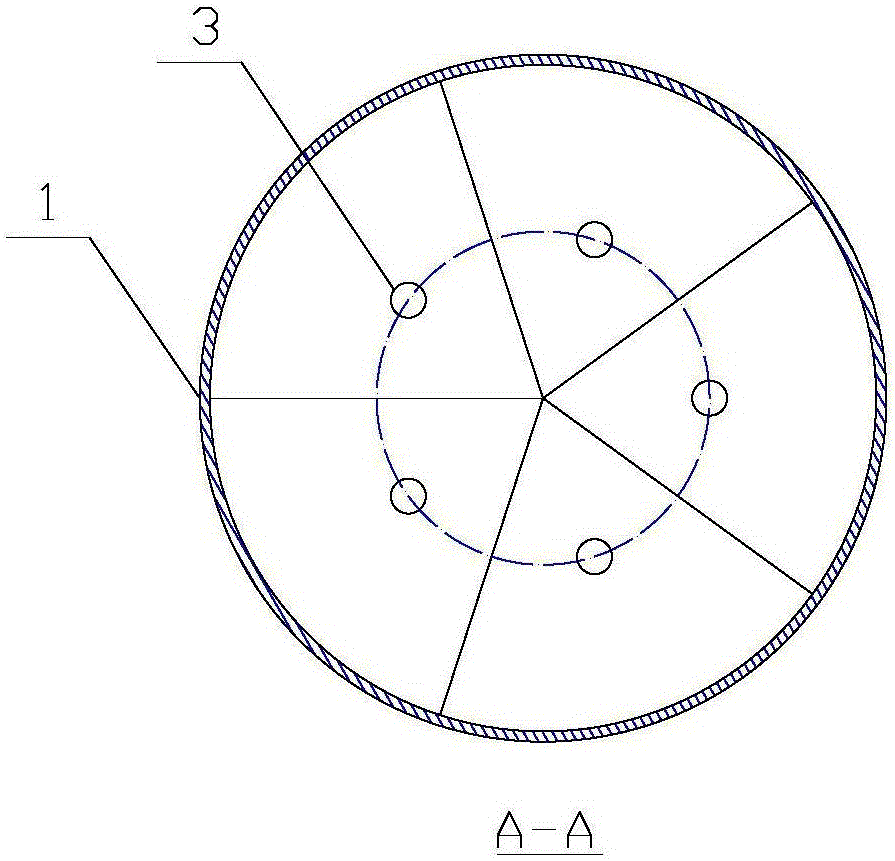

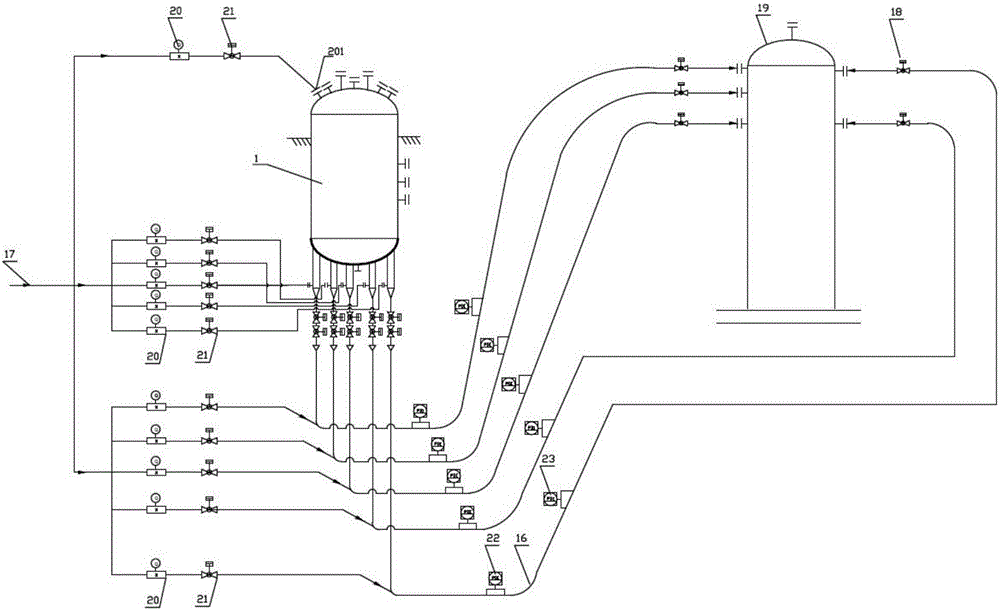

[0022] Such as figure 1 As shown, a pressure-feeding high-pressure dense-phase five-way pneumatic conveying tank includes an outer cylinder body 1 and five cone buckets 4, and the angle between the busbars of each cone bucket 4 is 10° to 30°. All cone buckets 4 are vertically arranged inside the outer cylinder 1 and evenly distributed along the circumference of the outer cylinder 1. The maximum horizontal section of each cone 4 is located on the same horizontal plane, and the vertical distance from the center point of the circular outlet 3 at the bottom of each cone to the inner wall of the outer cylinder 1 is a quarter of the inner diameter of the outer cylinder, such as figure 2 shown. All cone buckets are connected by smooth intersecting lines to form a multi-cone bucket interconnection. An intersection point of the circumference of the largest horizontal section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com