Water treatment device and method by using power plant waste heat

A technology for water treatment devices and waste heat in power plants, applied in seawater treatment, multi-stage water treatment, water/sewage treatment, etc. The effect of utilizing efficiency and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

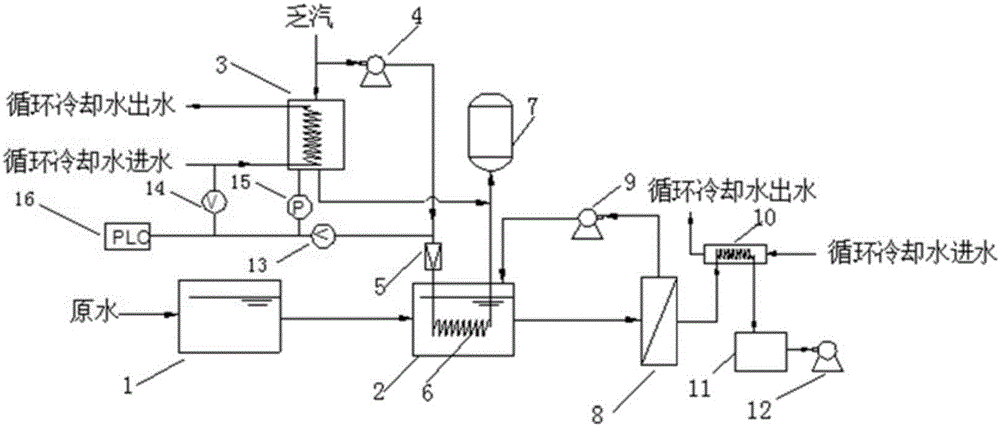

[0042] Based on the method for water treatment using waste heat from a power plant by a water treatment device, taking desulfurization wastewater from a coal-fired power plant as a treatment object, the method includes the following steps:

[0043] Step 1, the desulfurization wastewater is pretreated by chemical precipitation, softening, flocculation and precipitation to remove pollutants such as heavy metals, suspended solids and hardness in the wastewater, and then enters the heating tank 2;

[0044] Step 2, in the exhausted steam discharged from the low pressure cylinder of the steam turbine, the exhausted steam enters the steam compressor 5 after being drawn out by the air extraction pump 4;

[0045]In step 3, the exhausted steam compressed by the steam compressor 5 is heated to 90°C and then enters the heat exchanger 6 in the heating pool 2, and the desulfurization wastewater in the heating pool 2 is heated by the heat exchanger 6, and the exhausted steam is condensed at t...

Embodiment 2

[0052] Based on the method for the water treatment device utilizing the waste heat of the power plant for water treatment, the seawater of a coastal coal-fired power plant is taken as the treatment object, and the seawater desalination treatment includes the following steps:

[0053] Step 1: First, the sea water is pumped into the conditioning tank, and then through pretreatment such as softening, flocculation sedimentation, filtration, etc., to remove pollutants such as suspended solids and hardness in the wastewater, and then enter the heating tank 2;

[0054] Step 2, in the exhausted steam discharged from the low pressure cylinder of the steam turbine, the exhausted steam enters the steam compressor 5 after being drawn out by the air extraction pump 4;

[0055] Step 3, the spent steam compressed by the steam compressor 5 is heated to 65°C and then enters the heat exchanger 6 in the heating pool 2, and the seawater in the heating pool 2 is heated by the heat exchanger 6, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap