Treating reagent applicable to high-salt pesticide wastewater and preparation method thereof

A technology for pesticide wastewater and chemical treatment, which is applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of non-compliance with environmental protection requirements, complex pollutant components, polluted water bodies, etc. problems, to achieve the effect of excellent coagulation ability, large vitriolization and easy handling, and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

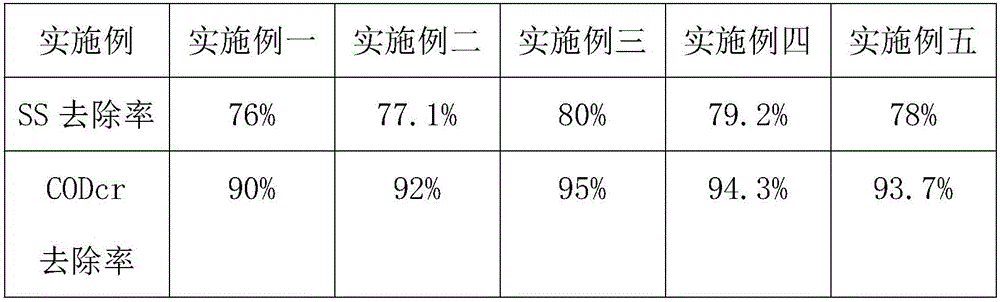

Examples

Embodiment 1

[0021] A treatment agent suitable for high-salt pesticide wastewater proposed by the present invention includes the following raw materials in parts by weight: 75 parts of rice straw, 52 parts of attapulgite raw ore, 88 parts of 1mol / L dilute hydrochloric acid, 75 parts of aluminum sulfate, and chitosan 10 servings.

[0022] Its preparation method comprises the following steps:

[0023] S1. Drying the rice straw with the specific gravity at 74°C, crushing it and passing it through a 20-mesh sieve to obtain material A;

[0024] S2. Fill material A into a 30mL ceramic crucible, compact it slightly after filling, put the lid on and place in a muffle furnace for carbonization at 530°C for 3.4h, then cool naturally;

[0025] S3. After the material in S2 is naturally cooled to room temperature, take it out and grind it, pass it through a 20-mesh sieve, and set aside;

[0026] S4, take the attapulgite raw ore of the specific gravity and carry out air-dried crushing and grinding, an...

Embodiment 2

[0031] A treatment agent suitable for high-salt pesticide wastewater proposed by the present invention includes the following raw materials in parts by weight: 78 parts of rice straw, 54 parts of attapulgite raw ore, 92 parts of 1mol / L dilute hydrochloric acid, 80 parts of aluminum sulfate, and chitosan 12 servings.

[0032] Its preparation method comprises the following steps:

[0033] S1. Dry the rice straw with the specific gravity at 85° C., crush it and pass it through a 20-mesh sieve to obtain material A;

[0034] S2. Fill material A into a 30mL ceramic crucible, compact it slightly after filling, put the lid on and place it in a muffle furnace for carbonization at 540°C for 3.6h, then cool naturally;

[0035] S3. After the material in S2 is naturally cooled to room temperature, take it out and grind it, pass it through a 20-mesh sieve, and set aside;

[0036] S4, take the attapulgite raw ore of the specific gravity and carry out air-dried crushing and grinding, and th...

Embodiment 3

[0041] A treatment agent suitable for high-salt pesticide wastewater proposed by the present invention includes the following raw materials in parts by weight: 65 parts of rice straw, 50 parts of attapulgite raw ore, 84 parts of 1mol / L dilute hydrochloric acid, 70 parts of aluminum sulfate, and chitosan 9 servings.

[0042] Its preparation method comprises the following steps:

[0043] S1. Dry the rice straw with the specific gravity at 80° C., crush it and pass it through a 20-mesh sieve to obtain material A;

[0044] S2. Fill material A into a 30mL ceramic crucible, compact it slightly after filling, put the lid on and place it in a muffle furnace for carbonization at 550°C for 3.2h, then cool naturally;

[0045] S3. After the material in S2 is naturally cooled to room temperature, take it out and grind it, pass it through a 20-mesh sieve, and set aside;

[0046] S4, take the attapulgite raw ore of the specific gravity and carry out air-dried crushing and grinding, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com