Preparation method of composite material for polypropylene modification, and product thereof

A technology of composite materials and polypropylene, which is applied in the field of preparation of composite materials for polypropylene modification, can solve the problems of insignificant performance improvement of polypropylene, poor modification effect of polypropylene, and inability to combine organically, and achieve extreme chemical stability Good, improve processing fluidity, improve the effect of surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

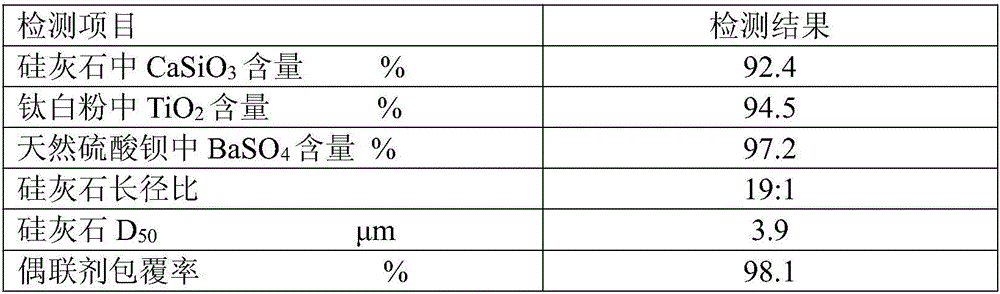

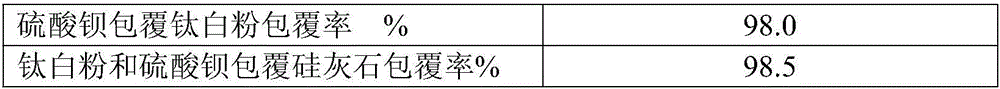

Embodiment 1

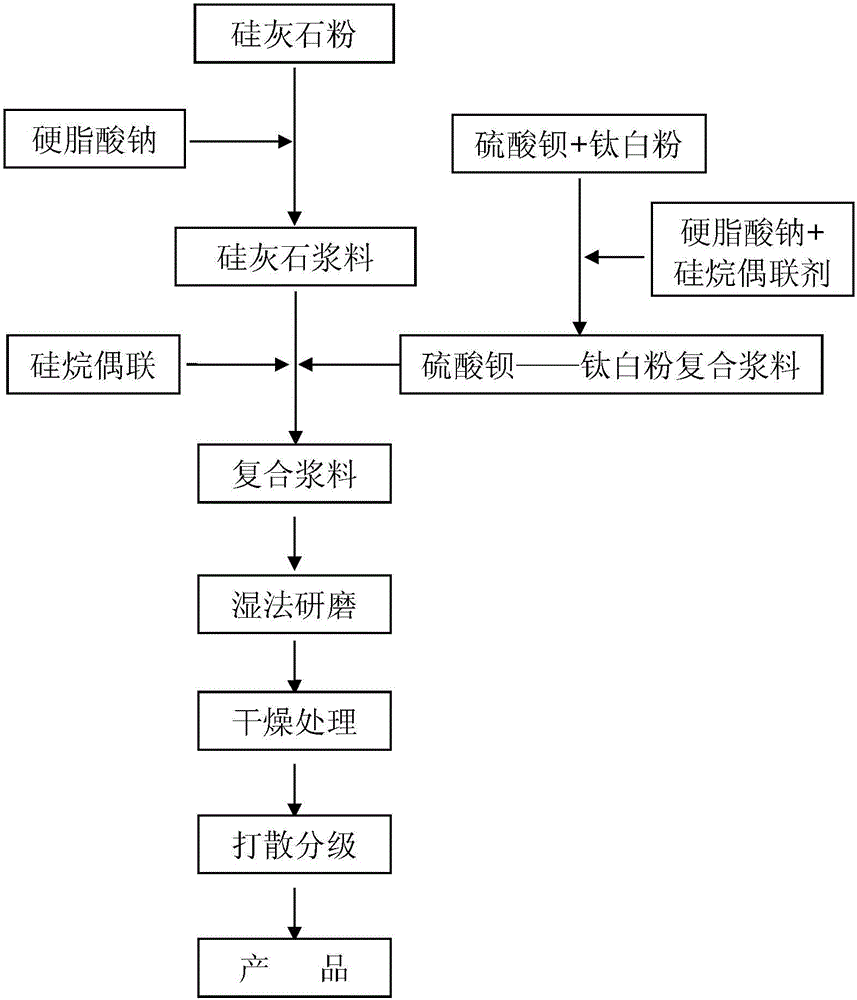

[0029] A kind of preparation method of composite material for polypropylene modification, is characterized in that, comprises the following steps:

[0030] (1) Adjust the 400-600 mesh wollastonite powder with water to form a slurry with a mass concentration of 50%-60%, and add sodium stearate as a dispersant while preparing the slurry, and the addition amount is 2‰ of the dry wollastonite powder mass , to improve the dispersibility and grindability of the slurry.

[0031] (2) Mix 400-600 mesh barium sulfate and 300-400 mesh rutile titanium dioxide with water at a mass ratio of 4:1 to form a composite slurry with a mass concentration of 65%, and add 3% sodium stearate as a dispersant at the same time , Add 2‰ of D-7080 silane coupling agent as a dispersant and surface modifier.

[0032] (3) Feed the titanium dioxide-barium sulfate composite slurry prepared in (2) into the wet vertical stirring mill through a diaphragm pump, the mill speed is 200r / min, and the content of the sl...

Embodiment 2

[0041] A kind of preparation method of composite material for polypropylene modification, is characterized in that, comprises the following steps:

[0042] (3) Adjust the 400-600 mesh wollastonite powder with water into a slurry with a mass concentration of 50%-60%, and add sodium stearate as a dispersant while preparing the slurry, and the addition amount is 3‰ of the wollastonite dry powder mass , to improve the dispersibility and grindability of the slurry.

[0043] (4) Mix 400-600 mesh barium sulfate and 300-400 mesh rutile titanium dioxide with water at a mass ratio of 5:1 to form a composite slurry with a mass concentration of 68%, and add 3% sodium stearate as a dispersant at the same time , Add 2‰ of D-7080 silane coupling agent as a dispersant and surface modifier.

[0044] (3) Feed the titanium dioxide-barium sulfate composite slurry prepared in (2) into the wet vertical stirring mill through a diaphragm pump, the mill speed is 200r / min, and the content of the slurr...

Embodiment 3

[0051] A kind of preparation method of composite material for polypropylene modification, is characterized in that, comprises the following steps:

[0052] (5) Adjust the 400-600 mesh wollastonite powder with water into a slurry with a mass concentration of 50%-60%, and add sodium stearate as a dispersant while preparing the slurry, and the addition amount is 5‰ of the wollastonite dry powder mass , to improve the dispersibility and grindability of the slurry.

[0053] (6) Mix 400-600 mesh barium sulfate and 300-400 mesh rutile titanium dioxide with water at a mass ratio of 6:1 to form a composite slurry with a mass concentration of 70%, and add 3% sodium stearate as a dispersant at the same time , Add 2‰ of D-7080 silane coupling agent as a dispersant and surface modifier.

[0054] (3) Feed the titanium dioxide-barium sulfate composite slurry prepared in (2) into the wet vertical stirring mill through a diaphragm pump, the mill speed is 250r / min, and the content of the slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com