A kind of modified pitch for producing anode carbon block and preparation method of modified pitch

A technology for modifying asphalt and anode carbon blocks, which is applied in the chemical field, can solve the problems of increased anode replacement frequency, increased labor intensity of workers, reduced electrolytic cell efficiency, etc., and achieves a simple and easy-to-understand preparation method, improved coking properties, and reduced viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

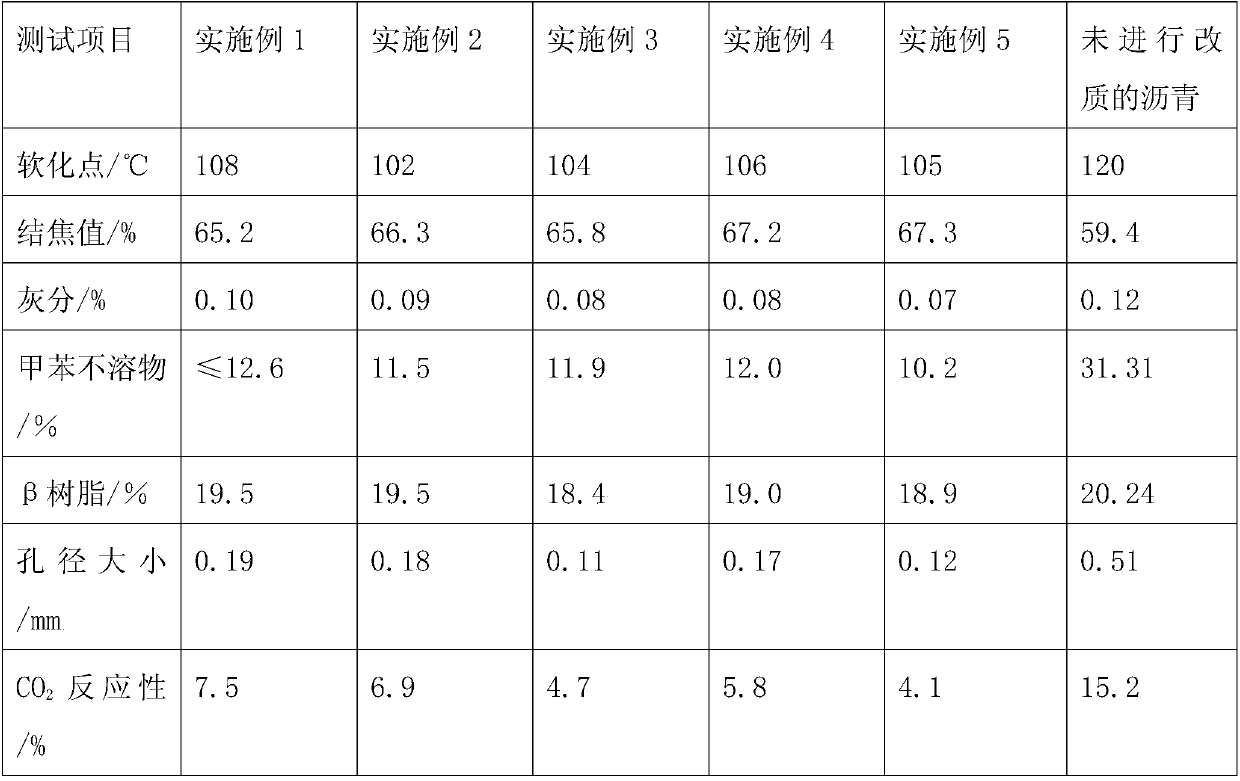

Examples

Embodiment 1

[0025] 1. Raw material preparation:

[0026] A modified asphalt for the production of anode carbon blocks, comprising 50 parts by weight of asphalt, 5 parts of asphalt modifier A, and 3 parts of asphalt modifier B;

[0027] Among them, the asphalt modifier A includes 1 part of modified diatomite and 2 parts of modified bentonite in parts by weight;

[0028] Among them, the modified diatomaceous earth is calcined at 500° C. for 10 min, and then pulverized with ultrasonic waves to a particle size of 100 mesh after cooling.

[0029] Among them, the modified bentonite is mechanically pulverized to 50 meshes and then thermally cracked in a steam thermal cracking device for 2 seconds; the temperature of the steam thermal cracking device is 350°C, and the steam thermal cracking device is added after being vacuumed Argon.

[0030] Among them, the asphalt modifier B includes 0.5 part of n-decyl stearate, 0.1 part of dibutyl phthalate, 0.1 part of ultrafine graphite powder and 0.5 part of fluori...

Embodiment 2

[0039] 1. Raw material preparation:

[0040] A modified asphalt for the production of anode carbon blocks, comprising 85 parts by weight of asphalt, 15 parts of asphalt modifier A, and 8 parts of asphalt modifier B;

[0041] Among them, the asphalt modifier A includes 5 parts of modified diatomite and 8 parts of modified bentonite in parts by weight;

[0042] Among them, the modified diatomaceous earth is calcined at 600° C. for 30 min, and then pulverized by ultrasonic waves to a particle size of 150 mesh after cooling.

[0043] Among them, the modified bentonite is mechanically pulverized to 100 meshes and then thermally cracked in a steam thermal cracking device for 5 seconds; the temperature of the steam thermal cracking device is 450°C, and the steam thermal cracking device is added after being vacuumed Argon.

[0044] Among them, the asphalt modifier B includes 1.5 parts of n-decyl stearate, 0.8 parts of dibutyl phthalate, 3 parts of ultrafine graphite powder and 2 parts of fluor...

Embodiment 3

[0053] 1. Raw material preparation:

[0054] A modified asphalt for the production of anode carbon blocks, comprising 64 parts by weight of asphalt, 8 parts of asphalt modifier A, and 5 parts of asphalt modifier B;

[0055] Wherein, the asphalt modifier A includes 3 parts of modified diatomite and 4 parts of modified bentonite in parts by weight;

[0056] Among them, the modified diatomaceous earth is calcined at 550° C. for 18 min, and then pulverized with ultrasonic waves to a particle size of 120 mesh after cooling.

[0057] Among them, the modified bentonite is mechanically pulverized to 60 meshes and then thermally cracked in a steam thermal cracking device for 3 seconds; the temperature of the steam thermal cracking device is 380°C, and the steam thermal cracking device is added after vacuuming Argon.

[0058] Among them, the asphalt modifier B includes 0.8 parts of n-decyl stearate, 0.4 parts of dibutyl phthalate, 1.5 parts of ultrafine graphite powder and 1.0 part of fluoride i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com