Method of manufacturing integrated electrode with three-dimensional conductive network

A conductive network and electrode technology, which is applied in the field of preparation of integrated electrodes, can solve the problems of the limitation of electrode active material diversity and shape diversity, the inability to obtain large-area integrated electrodes, and the complexity of the conductive network construction method, achieving cost reduction. low cost, simple preparation process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

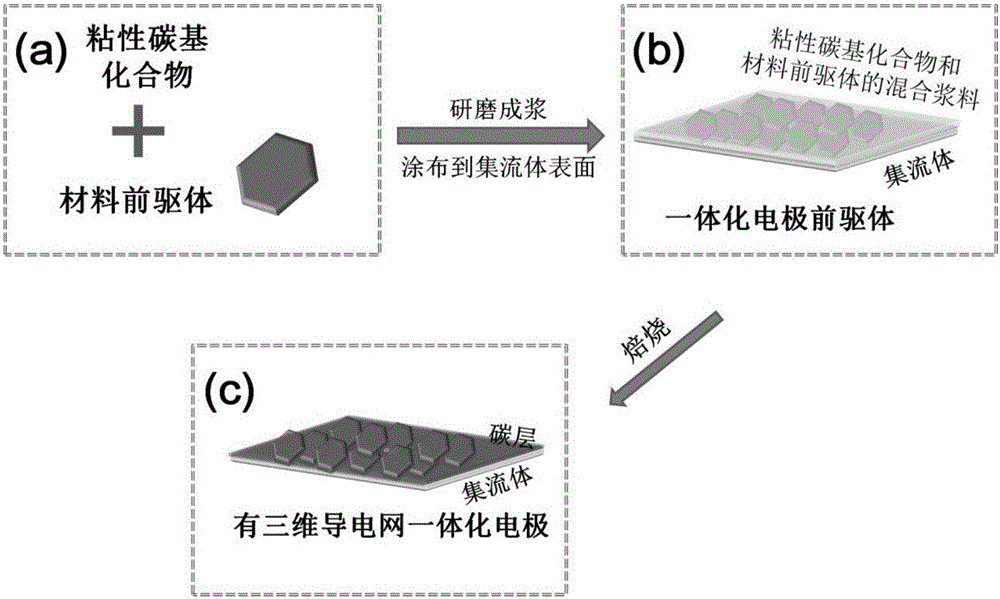

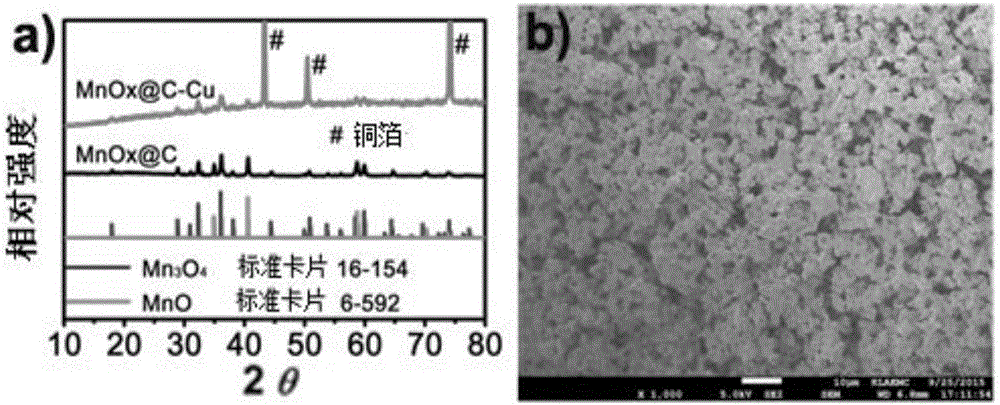

[0024] A method for preparing an integrated electrode with a three-dimensional conductive network, using manganese oxide as an active material, polyvinylpyrrolidone with a molecular weight of 1.3 million as a sticky carbon-based compound, and copper foil as a current collector. The synthesis route is as follows figure 1 As shown, the steps are as follows:

[0025] 1) Synthesize manganese trioxide polyhedron (PVP) according to the existing method, refer to J.Phys.Chem.C2007,111,14694, and accurately weigh 0.250g and 0.500 g, transferred to a mortar, added 0.5 mL of deionized water, and ground to obtain a uniformly mixed slurry;

[0026] 2) Apply the uniformly mixed slurry to the surface of the copper foil with a blade coating method, the coating thickness is 30 μm, and dry at room temperature for 24 hours to completely volatilize the water to obtain the integrated electrode precursor;

[0027] 3) Transfer the above-mentioned integrated electrode precursor into a tube furnace a...

Embodiment 2

[0032] A preparation method of an integrated electrode with a three-dimensional conductive network, cobalt carbonate CoCO 3 Co(OH) 2 It is the active material precursor, polyvinylpyrrolidone (PVP) with a molecular weight of 1.3 million is a sticky carbon-based compound, and nickel foam is used as a current collector. The synthetic route is as follows figure 1 As shown, the steps are as follows:

[0033] 1) Accurately weigh 0.500g of PVP and 0.500g of cobalt hydroxide carbonate with the mass ratio of viscous carbon-based compound and active material precursor at 1:1, transfer them to a mortar, add 1mL of deionized water, and grind to obtain a uniform mixture the slurry;

[0034] 2) Coating the uniformly mixed slurry on the surface of nickel foam with a coating thickness of 20 μm, and vacuum drying at 50° C. for 8 hours to completely volatilize the water to obtain the integrated electrode precursor;

[0035] 3) Transfer the above-mentioned integrated electrode precursor into ...

Embodiment 3

[0038] A method for preparing an integrated electrode with a three-dimensional conductive network, using tungsten disulfide (WS 2 ) as the active substance, polyacrylonitrile (PAN) as the sticky carbon-based compound, and copper foil as the current collector, the synthetic route is as follows figure 1 As shown, the steps are as follows:

[0039] 1) Accurately weigh 0.100g PAN and 0.500g tungsten sulfide with the mass ratio of viscous carbon-based compound and active substance at 0.2:1, transfer them to a mortar, add 1.0mL of dimethylformamide (DMF), and grind to obtain uniform slurry;

[0040] 2) The uniformly mixed slurry was coated on the surface of copper foil with a coating thickness of 30 μm by doctor blade coating method, and vacuum-dried at 80 °C for 8 h to completely volatilize DMF to obtain the integrated electrode precursor.

[0041] 3) Transfer the above-mentioned integrated electrode precursor into a tube furnace and heat at 3°C min -1 The heating rate was raise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com