Tunable medium-infrared optical fiber mixed gas cascaded Raman laser

A technology of Raman lasers and mixed gases, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems of limited effective action distance and high pumping threshold, so as to improve the pumping intensity and effective action distance, The effect of high output power and convenient design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

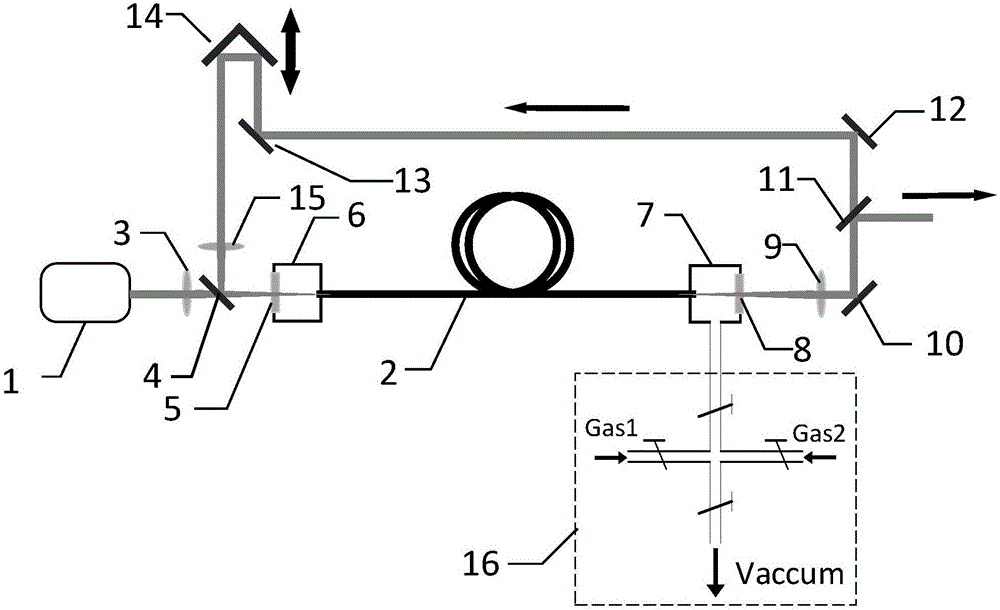

[0035] Such as figure 1 As shown, the tunable mid-infrared fiber mixed gas cascaded Raman laser of this embodiment includes a near-infrared tunable laser pump source 1, a hollow-core fiber 2, an input gas cavity 6, an output gas cavity 7, and a coupling output mirror 11 , the two ends of the hollow-core optical fiber 2 are respectively sealed in the input gas cavity 6 and the output gas cavity 7;

[0036] The input gas cavity 6 is provided with an input window 5, and an input coupling assembly for coupling the pump light to the hollow-core optical fiber 2 is provided between the near-infrared tunable laser pump source 1 and the input window 5, and the input coupling assembly includes a first focusing The coupling lens 3 and the dichroic mirror 4, the first focusing coupling lens 3 and the dichroic mirror 4 are arranged in sequence al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com