Enteric composite drug-loading system with halloysite nanotube as skeleton and preparation method thereof

A technology of halloysite nanotubes and skeletons, which is used in pharmaceutical formulations, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc. The problems of small strength and high preparation cost can achieve the effect of improving drug loading rate and improving slow-release enteric solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

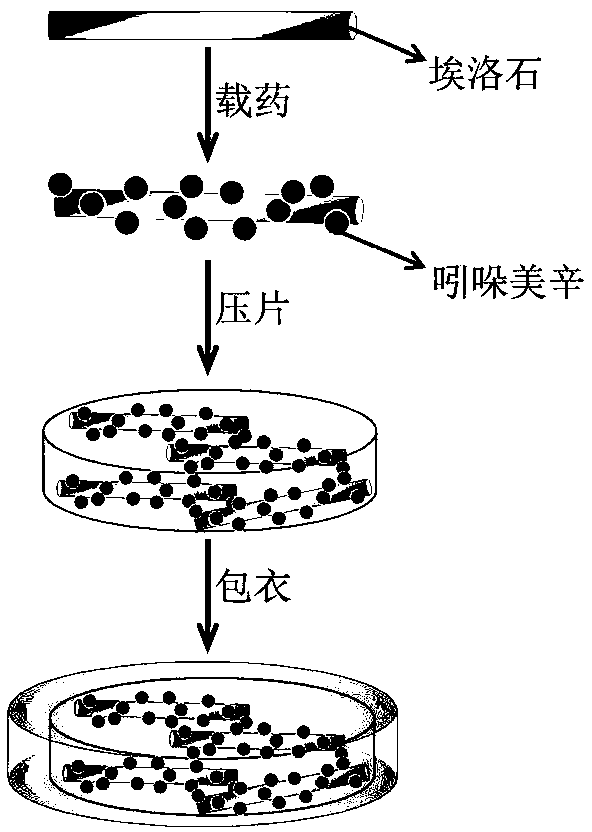

Method used

Image

Examples

Embodiment 1

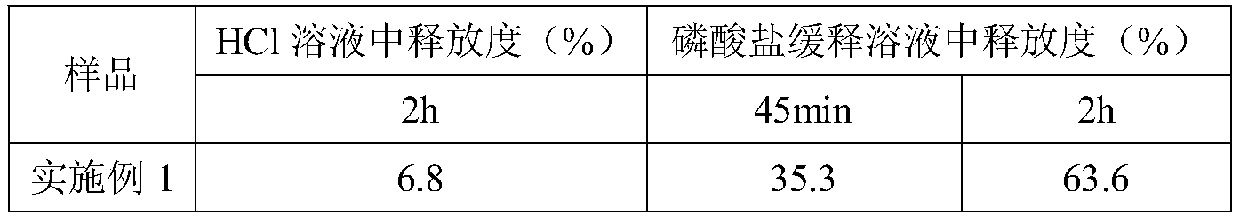

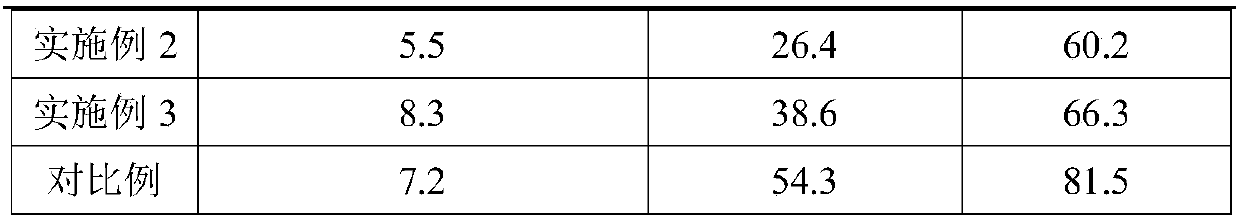

[0017] (1) Weigh 4g of acetone, 0.025g of indomethacin, and 0.25g of halloysite nanotubes respectively, then add indomethacin into the acetone, stir and mix to form solution A, and slowly drop solution A with a syringe into 0.25g of halloysite nanotubes, stirred evenly at 30°C, dried in a vacuum oven at 50°C, and then placed the dried powder in a tablet press to form tablets with a diameter of 1 cm and a thickness of 0.15 cm. The tablet weighs 0.275g, and each tablet contains 0.025g of indomethacin;

[0018] (2) Weigh 0.5g of hypromellose phthalate, 0.1g of soluble starch, and 0.003g of polyvinylpyrrolidone (Woke, PVP-K30, GR 100g), and add them to 15ml of absolute ethanol and 4ml of In the mixed solution of deionized water, stir for 30 minutes to prepare solution B;

[0019] (3) Use the dipping-pulling method to slowly and uniformly immerse the tablet prepared in step (1) into the solution B of step (2) cooled to 0°C, and slowly take it out after 5 seconds of composite cross...

Embodiment 2

[0021] (1) Weigh 2g of acetone, 0.030g of indomethacin, and 0.35g of halloysite nanotubes respectively, then add indomethacin into the acetone, stir and mix to form solution A, and slowly drop solution A with a syringe into 0.35g of halloysite nanotubes, stirred evenly at 37°C, dried in a vacuum oven at 40°C, and then placed the dry powder in a tablet press to be pressed into tablets with a diameter of 1 cm and a thickness of 0.22 cm. The weight of the tablet is 0.38g, and each tablet contains 0.030g of indomethacin;

[0022] (2) Weigh 0.6g hypromellose phthalate, 0.2g soluble starch, 0.002g polyvinylpyrrolidone (Wokai, PVP-K30, GR 100g), add to 20ml absolute ethanol and 5ml In the mixed solution of deionized water, stir for 60 minutes to prepare solution B;

[0023] (3) Use the dipping-pulling method to slowly and uniformly immerse the tablet prepared in step (1) into the solution B of step (2) cooled to 0°C, and slowly take it out after 3 seconds of composite crosslinking, ...

Embodiment 3

[0025] (1) Weigh 4g of acetone, 0.040g of indomethacin and 0.30g of halloysite nanotubes respectively, then add indomethacin into the acetone, stir and mix to form solution A, and slowly drop solution A with a syringe into 0.30 g of halloysite nanotubes, stirred evenly at 40°C, placed in a vacuum oven at 50°C, and dried, and then the dried powder was placed in a tablet press to be pressed into tablets with a diameter of 1 cm and a thickness of 0.18 cm. The tablet weighs 0.34g, and each tablet contains 0.040g of indomethacin;

[0026] (2) Weigh 0.4g hypromellose phthalate, 0.3g soluble starch, 0.01g polyvinylpyrrolidone (Wokai, PVP-K30, GR 100g), add to 30ml absolute ethanol and 5ml In the mixed solution of deionized water, stir for 60 minutes to prepare solution B;

[0027] (3) Use the dipping-pulling method to slowly and uniformly immerse the tablet prepared in step (1) into the solution B of step (2) cooled to 0°C, and slowly take it out after 3 seconds of composite crossli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| release amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com