Pd/WO3-RGO catalyst used for formic acid oxidation and preparation method thereof

A formic acid oxidation and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high price and poor stability of Pd metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

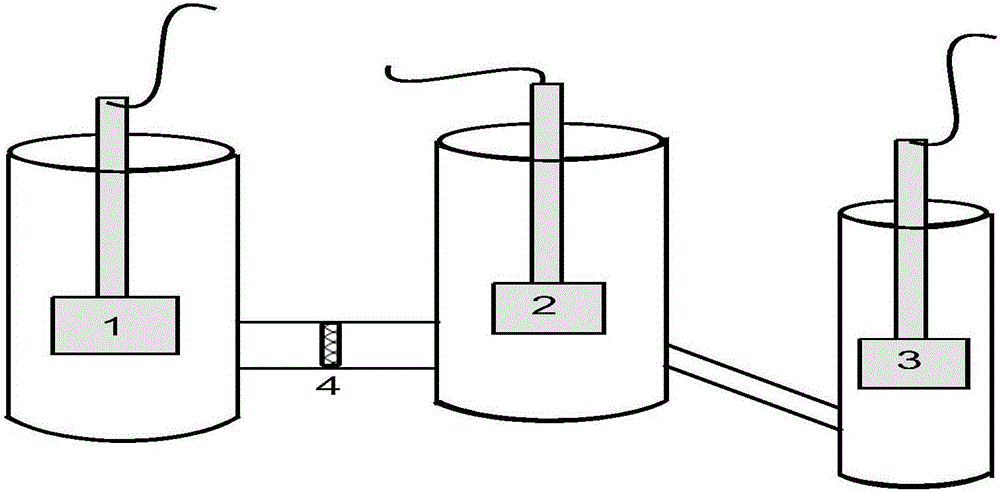

Method used

Image

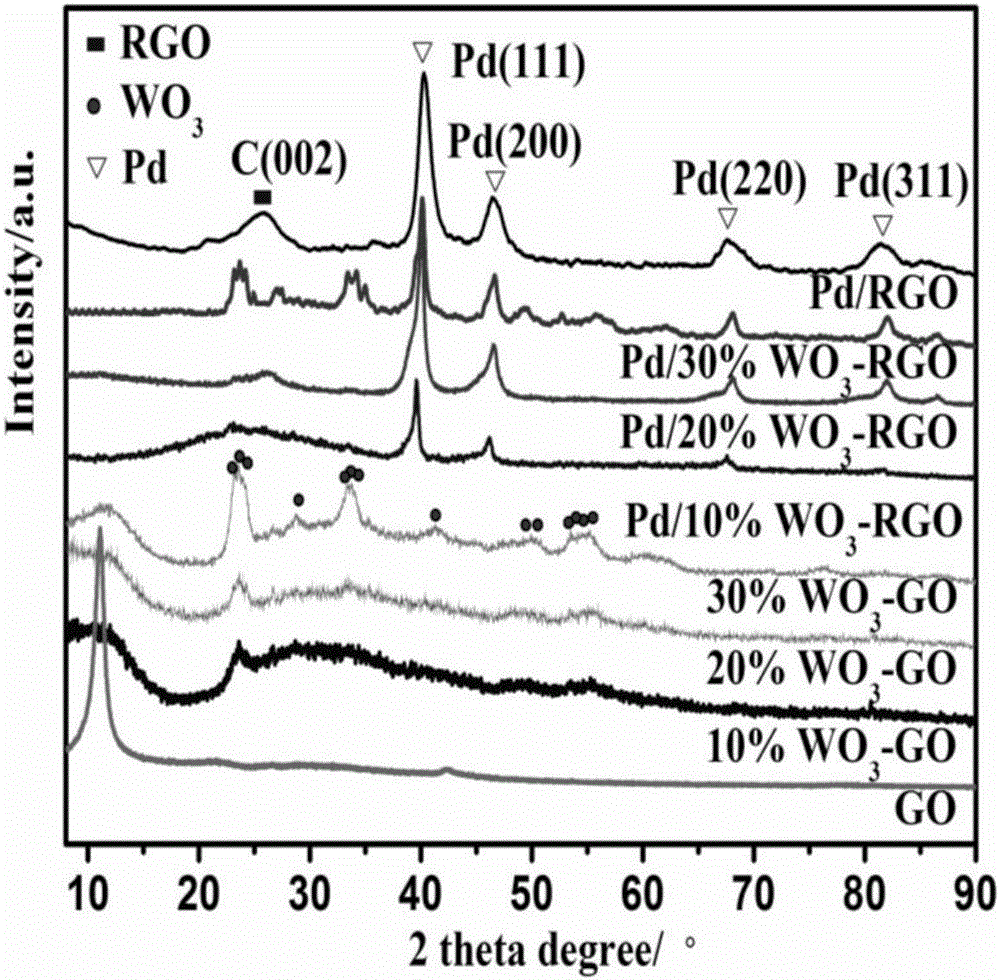

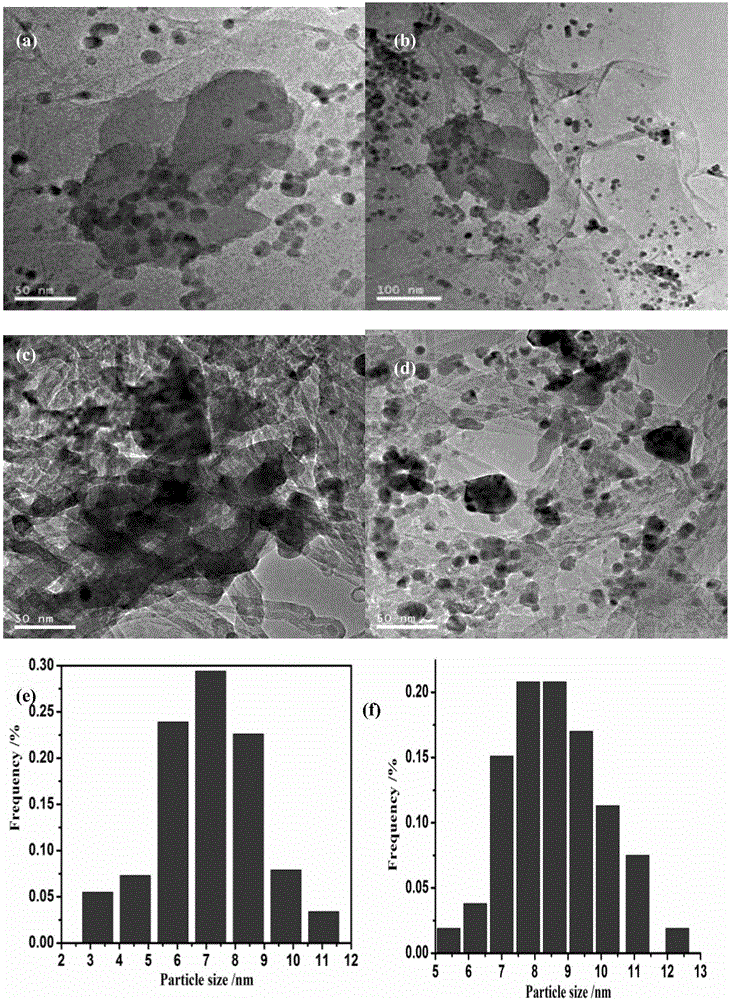

Examples

Embodiment 1

[0035] 1. Preparation of graphene oxide

[0036] Graphene oxide was synthesized by liquid phase oxidation by Hummers method. First, place a beaker containing 23 mL of concentrated sulfuric acid in an ice water bath, add 1 g of graphite powder, and sonicate for 20 min (10 min each time) until it is uniform. Then slowly add 3 g of potassium permanganate, stirring constantly in an ice water bath. After 2 h, the ice bath was completed, heated to 40 ℃, reacted for 40 min, and slowly added 50 mL of distilled water. After the end, add to 88 ℃, and continue to stir for 1 h. Add 20 mL of distilled water and 20 mL of 30% H 2 O 2 . Then it was centrifuged while hot, washed with distilled water to neutrality, and dried in a blast drying oven at 70°C.

[0037] 2. Prepare the carrier

[0038] 2.1 Preparation of 30% WO 3 -GO

[0039] Weigh 8.5714 g of AMT, add AMT and 20 mL of distilled water to a 50 mL beaker, and stir continuously to completely dissolve it. Then weigh 100 mg of the graphene ...

Embodiment 2

[0052] 1. Preparation of graphene oxide

[0053] Graphene oxide was synthesized by liquid phase oxidation by Hummers method. First, place a beaker containing 23 mL of concentrated sulfuric acid in an ice water bath, add 1 g of graphite powder, and sonicate for 20 minutes (10 minutes each time) until it is uniform. Then slowly add 3 g of potassium permanganate, stirring constantly in an ice water bath. After 2 h, the ice bath was completed, heated to 40 ℃, reacted for 40 min, and slowly added 50 mL of distilled water. After the end, add to 88 ℃, and continue to stir for 1 h. Add 20 mL of distilled water and 20 mL of 30% H 2 O 2 . Then it was centrifuged while hot, washed with distilled water to neutrality, and dried in a blast drying oven at 70°C.

[0054] 2 Preparation of WO 3 -GO

[0055] Prepare an AMT (ammonium metatungstate) solution with a mass concentration of 20%, and then add 100 mg of the graphene oxide prepared in step 1, and sonicate for 30 min (10 min each time) unti...

Embodiment 3

[0059] 1. Preparation of graphene oxide

[0060] Graphene oxide was synthesized by liquid phase oxidation by Hummers method. First, place a beaker containing 23 mL of concentrated sulfuric acid in an ice water bath, add 1 g of graphite powder, and sonicate for 20 minutes (10 minutes each time) until it is uniform. Then slowly add 3 g of potassium permanganate, stirring constantly in an ice water bath. After 2 h, the ice bath was completed, heated to 40 ℃, reacted for 40 min, and slowly added 50 mL of distilled water. After the end, add to 88 ℃, and continue to stir for 1 h. Add 20 mL of distilled water and 20 mL of 30% H 2 O 2 . Then it was centrifuged while hot, washed with distilled water to neutrality, and dried in a blast drying oven at 70°C.

[0061] 2 Preparation of WO 3 -GO

[0062] Prepare an AMT (ammonium metatungstate) solution with a mass concentration of 10%, then add 100 mg of the graphene oxide prepared in step 1, and sonicate for 30 min (10 min each time) until it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com