Two-dimensional conductive mica-loaded carbon nitride photocatalytic material and preparation method thereof

A technology of conductive mica and catalytic materials, which is applied in the field of photocatalysis, can solve the problems of affecting the photocatalytic effect of photocatalysts, low photocatalytic activity, difficulty in wide application, and reduced photocatalytic efficiency, so as to achieve improved photocatalytic performance, simple preparation method, The effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

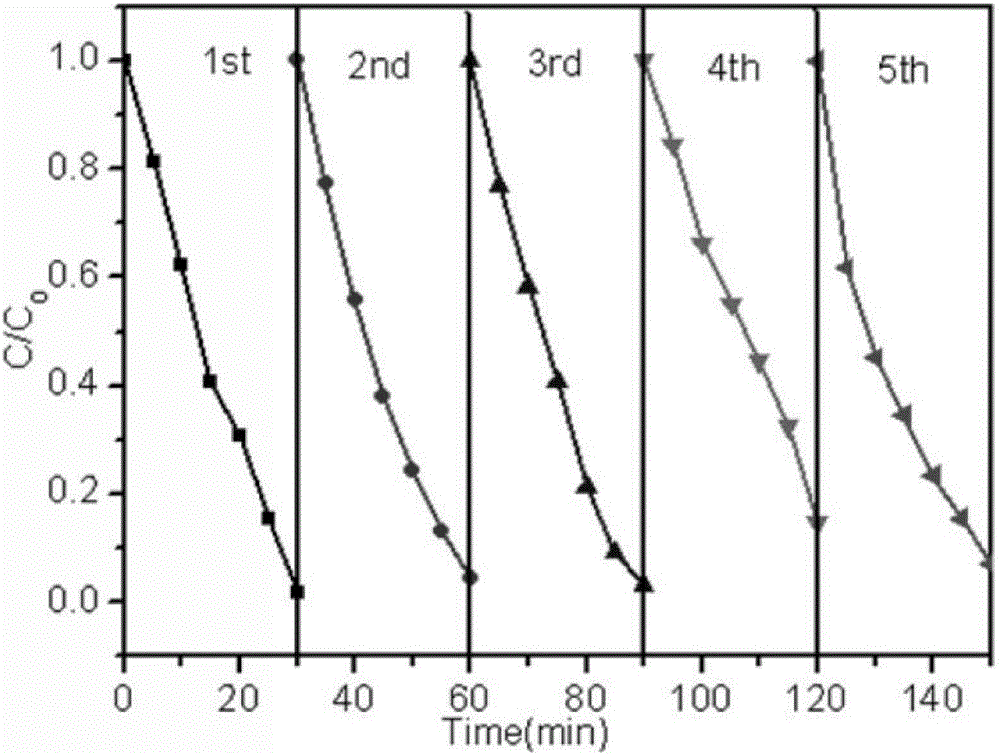

[0027] This embodiment discloses a preparation method of a two-dimensional conductive mica-loaded carbon nitride photocatalytic material, comprising the following steps:

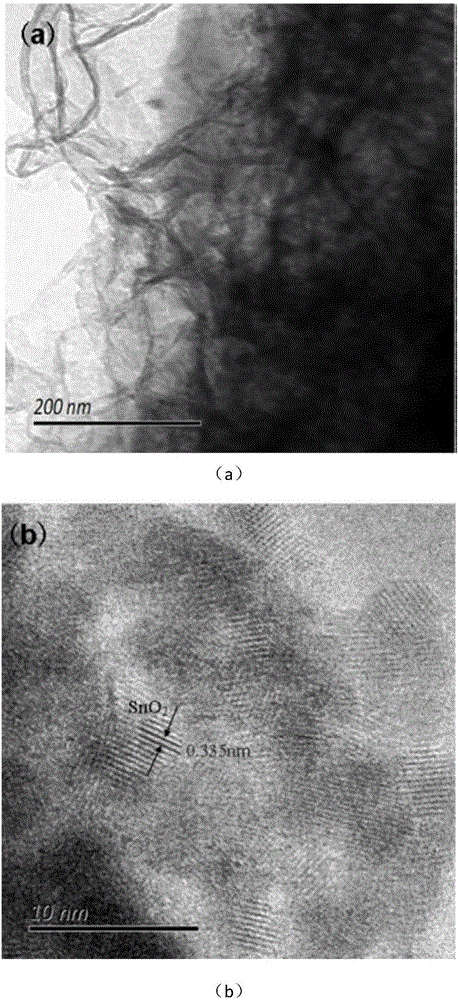

[0028] S1: Add 5g of mica powder to 200ml of ethanol, stir for 1 hour, fully swell, put it into a cell crusher, ultrasonicate at 400W for 4 hours, and then go through centrifugal drying, use the cavitation of ultrasonic waves to peel off the mica powder into two-dimensional sheets shaped mica. Among them, two-dimensional sheet mica is also called mica sheet.

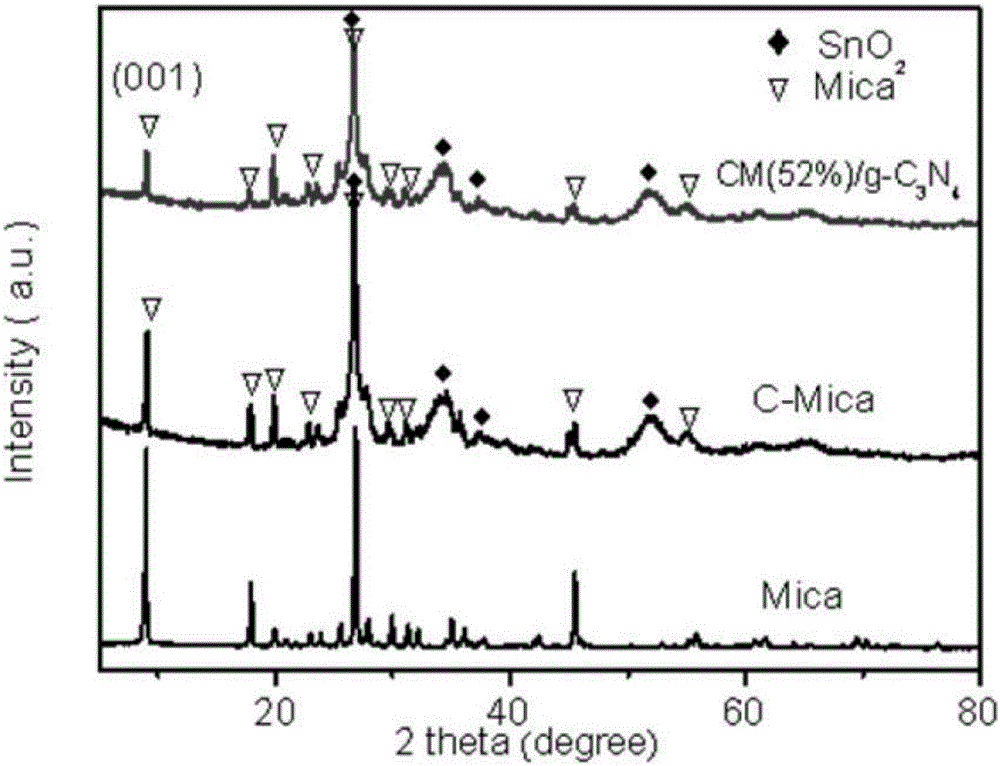

[0029] S2: Weigh 5 g of the obtained mica flakes, put them into 200 ml of deionized water, adjust the obtained suspension to PH=2 with hydrochloric acid, add 5 g of tin tetrachloride pentahydrate in a constant temperature water bath at 70° C., and stir in the water bath for 3 hours at a constant temperature. After washing and drying, the obtained pale yellow powder was calcined at 600° C. for 2 hours to obtain a two-dimensional flake mica coated with ...

Embodiment 2

[0034] This embodiment discloses a preparation method of a two-dimensional conductive mica-loaded carbon nitride photocatalytic material, comprising the following steps:

[0035] S1: Add 5g of mica powder to 200ml of ethanol, stir for 1 hour, fully swell, put it into a cell crusher, ultrasonicate at 400W for 4 hours, and then go through centrifugal drying, use the cavitation of ultrasonic waves to peel off the mica powder into two-dimensional sheets shaped mica. Among them, two-dimensional sheet mica is also called mica sheet.

[0036] S2: Weigh 5 g of the obtained mica flakes, put them into 200 ml of deionized water, adjust the obtained solution to PH=2 with hydrochloric acid, add 5 g of tin tetrachloride pentahydrate in a constant temperature water bath at 70 ° C, stir in the water bath for 3 hours at a constant temperature, and wash After drying, the obtained pale yellow powder was calcined at 600° C. for 2 hours to obtain a two-dimensional flake mica coated with a tin dio...

Embodiment 3

[0041] This embodiment discloses a preparation method of a two-dimensional conductive mica-loaded carbon nitride photocatalytic material, comprising the following steps:

[0042] S1: Add 5g of mica powder to 200ml of ethanol, stir for 1 hour, fully swell, put it into a cell crusher, ultrasonicate at 400W for 4 hours, and then go through centrifugal drying, use the cavitation of ultrasonic waves to peel off the mica powder into two-dimensional sheets shaped mica. Among them, two-dimensional sheet mica is also called mica sheet.

[0043] S2: Weigh 5 g of the obtained mica flakes, put them into 200 ml of deionized water, adjust the obtained solution to PH=2 with hydrochloric acid, add 5 g of tin tetrachloride pentahydrate in a constant temperature water bath at 70 ° C, stir in the water bath for 3 hours at a constant temperature, and wash After drying, the obtained pale yellow powder was calcined at 600° C. for 2 hours to obtain a two-dimensional flake mica coated with a tin dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com