Alcohol-based casting coating for precoated sand moulds and method for preparing alcohol-based casting coating

A technology of casting paint and coated sand, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of poor leveling, rough casting surface, short production cycle, etc., and achieve good paint brushing and leveling , Small volume shrinkage and deformation, and the effect of preventing shrinkage and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare 100 kg of paint.

[0022] (1) Weigh 64 kg of zircon powder with a particle size of 400 mesh, 1.4 kg of sodium bentonite, 2.1 kg of calcium bentonite, 1.6 kg of thermosetting phenolic resin powder, and 0.9 kg of polyvinyl butyral (viscosity of 8 seconds) powder , poured into a mixer with a sealed cover;

[0023] (2) Weigh 15 kg of ethanol and pour it into the mixer, cover the sealing cover, start the mixer, and mix for 2 hours to obtain a paste;

[0024] (3) Take out the above paste and put it into a mixing bucket with a sealed cover, add 15 kg of ethanol, stir and dilute for 15 minutes, and get the finished paint;

[0025] (4) Put the finished paint into the paint bucket and store it.

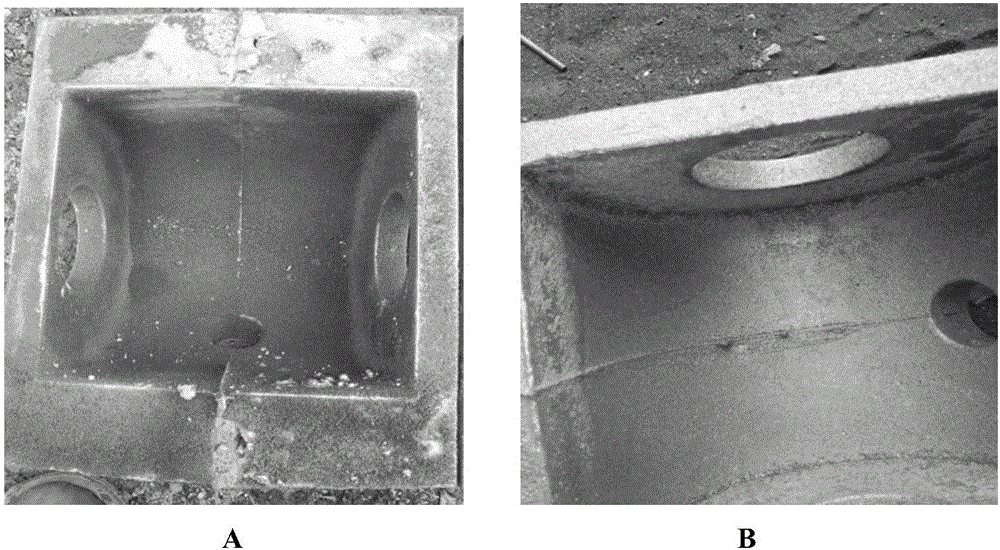

[0026] When using, stir the paint evenly, apply it on the coated sand mold with a soft wool brush, ignite and dry to pour the molten metal. The surface effect of the casting casted before and after the coating sand mold is used is as follows: figure 1 as shown, figure 1 A is...

Embodiment 2

[0028] Prepare 100 kg of paint.

[0029] (1) Weigh 66 kg of mullite powder with a particle size of 600 mesh, 1.4 kg of sodium bentonite, 1.8 kg of calcium bentonite, 1.2 kg of thermosetting phenolic resin powder, and 0.6 kg of polyvinyl butyral (viscosity of 8 seconds) powder , poured into a mixer with a sealed cover;

[0030] (2) Weigh 14.5 kg of ethanol and pour it into the mixer, cover the sealing cover, start the mixer, and mix for 2 hours to obtain a paste;

[0031] (3) Take out the above paste and put it into a mixing bucket with a sealed cover, add 14.5 kg of ethanol, stir and dilute for 15 minutes, and get the finished paint;

[0032] (4) Put the finished paint into the paint bucket and store it.

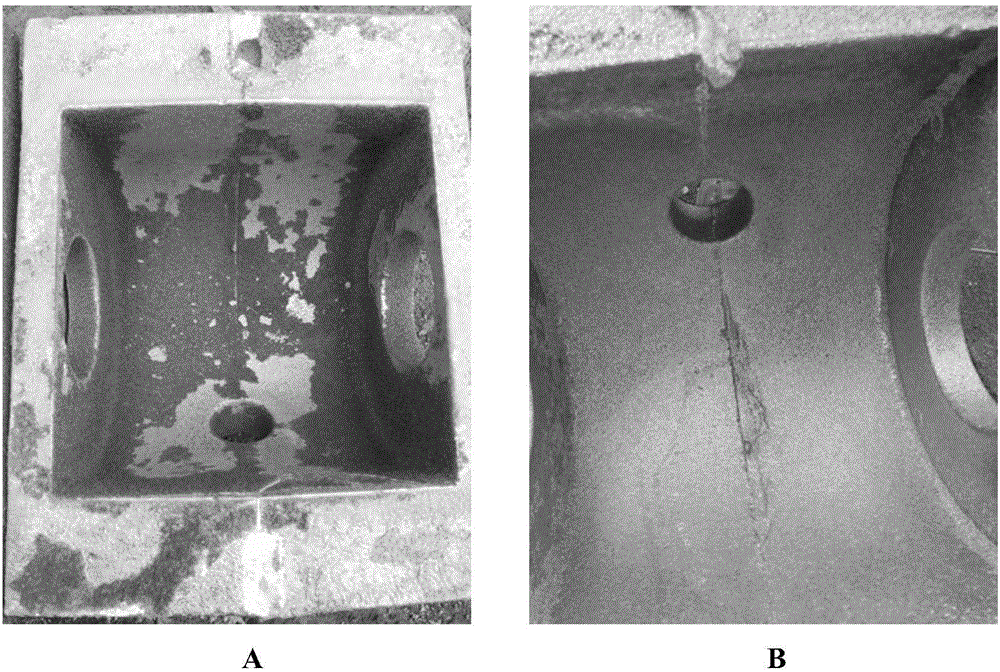

[0033] When using, stir the paint evenly, apply it on the coated sand mold with a soft wool brush, ignite and dry to pour the molten metal. The surface effect of the casting casted before and after the coating sand mold is used is as follows: figure 2 shown. figure 2 ...

Embodiment 3

[0035] Prepare 100 kg of paint.

[0036] (1) Weigh 63 kg of white corundum powder with a particle size of 600 mesh, 1.0 kg of sodium bentonite, 2.3 kg of calcium bentonite, 1.8 kg of thermosetting phenolic resin powder, and 0.9 kg of polyvinyl butyral (viscosity of 12 seconds) powder , poured into a mixer with a sealed cover;

[0037] (2) Weigh 15.5 kg of ethanol and pour it into the mixer, cover the sealing cover, start the mixer, and mix for 2 hours to obtain a paste;

[0038] (3) Take out the above paste and put it into a mixing bucket with a sealed cover, add 15.5 kg of ethanol, stir and dilute for 15 minutes, and get the finished paint;

[0039] (4) Put the finished paint into the paint bucket and store it.

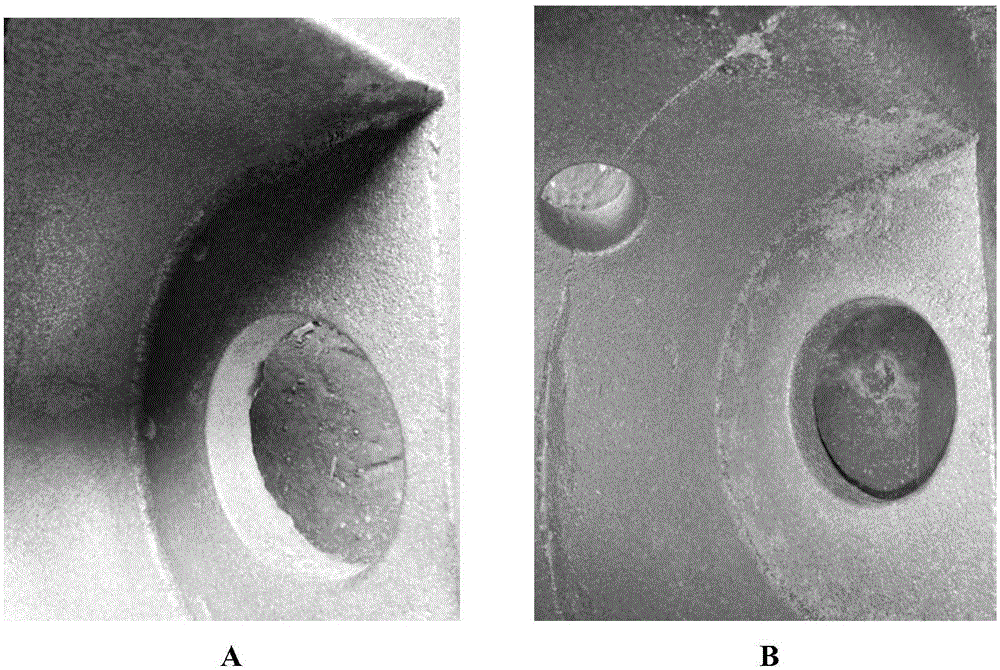

[0040] When using, stir the paint evenly, apply it on the coated sand mold with a soft wool brush, ignite and dry to pour the molten metal. The coated sand mold uses ordinary paint (using 325 mesh refractory powder, lithium-based bentonite as suspending agent, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com