A kind of interconnection solder and its interconnection forming method

A technology of solder and phase composition, applied in the field of materials, can solve the problem of long time consumption of transient liquid phase method, and achieve the effects of long time consumption, high melting point and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

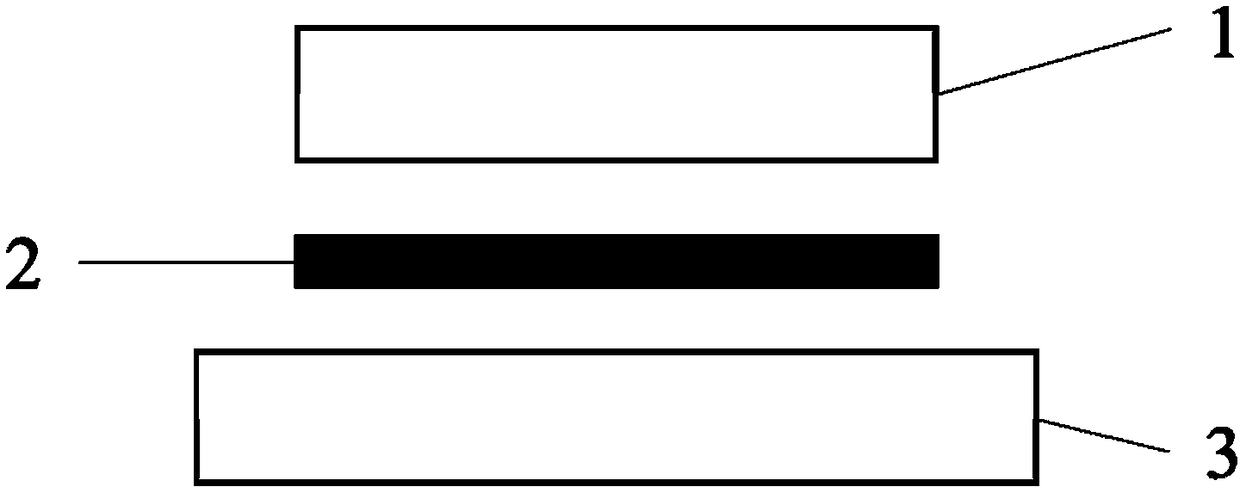

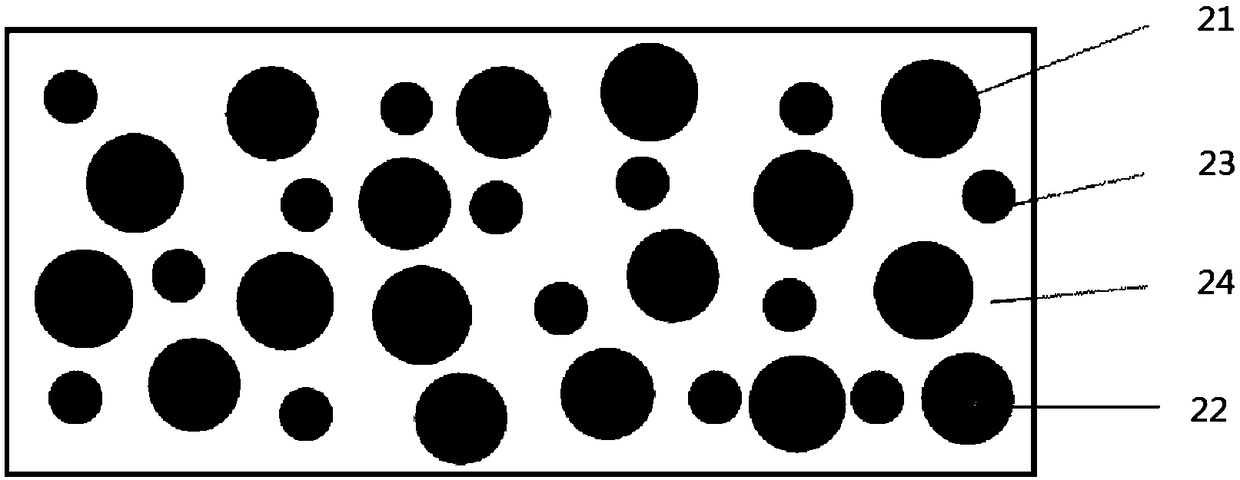

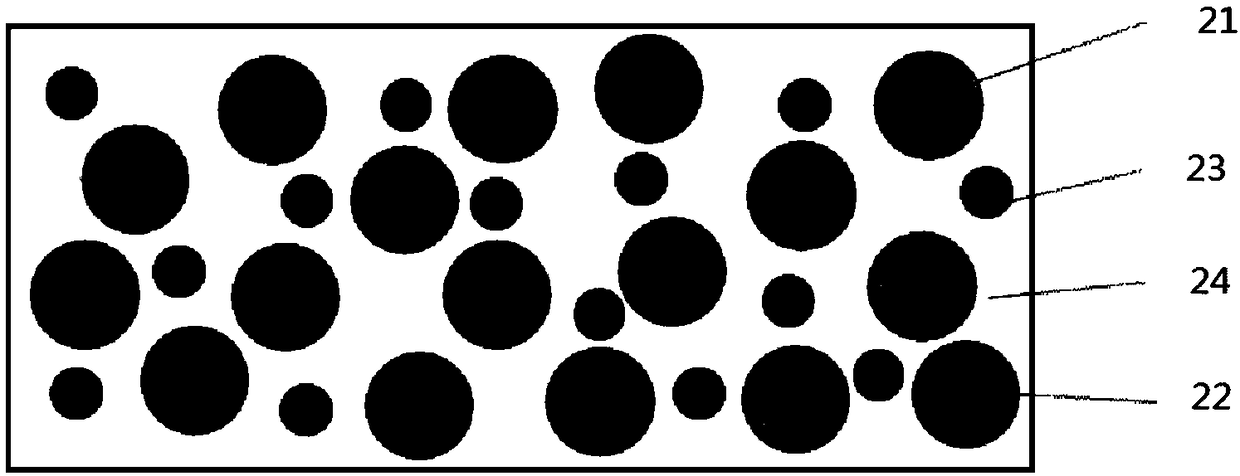

[0053] see figure 1 , figure 2 and Figure 4 As shown, a method for realizing a high melting point compound joint under an atmospheric environment, the connection method includes the following steps:

[0054] Ⅰ. Surface treatment of the materials to be connected: Use 1200# sandpaper to slightly polish the connection surface of the base material 1 and base material 3 3 to remove the oxide layer and oily impurities on the surface, and then immerse in absolute ethanol solution for ultrasonic cleaning 3 ~5min;

[0055] Ⅱ. Place the base material 33 on the lower layer, the base material 1 on the upper layer and the middle layer 22 in the middle to form a sandwich structure, the base material 1 and the base material 3 3 are placed horizontally and laterally. The base material 1 used above is a chip, the chip material is Si, SiC, GaN, InP or GaAs, the coating metal on the back of the chip is Ni, and the thickness of the Ni layer is 8 μm; the base material 3 3 is a pure Ni substra...

Embodiment 2

[0063] See attached figure 1 , figure 2 and Figure 4 As shown, a method for quickly realizing a hybrid joint connection between a high melting point compound and a high melting point metal in an atmospheric environment, the connection method includes the following steps:

[0064] Ⅰ. Surface treatment of the materials to be connected: Use 1200# sandpaper to polish the surface of the connection surface of the base material 1 and base material 3 3 to remove oil and impurities on the surface, and then immerse in absolute ethanol solution for ultrasonic cleaning for 3-5 minutes.

[0065] Ⅱ. Place the base material 33 on the lower layer, the base material 1 on the upper layer and the middle layer 22 in the middle to form a sandwich structure, the base material 1 and the base material 3 3 are placed horizontally and laterally. The base material 1 used above is a chip, the chip material is Si, SiC, GaN, InP or GaAs, the coating metal on the back of the chip is Ni, and the thickness ...

Embodiment 3

[0072] see figure 1 and Figure 4 As shown, a method for quickly realizing the connection of high-melting point compounds, high-melting point metals and third-phase metal mixed tissue joints in an atmospheric environment, the connection method includes the following steps:

[0073] Ⅰ. Surface treatment of the materials to be connected: Use 1200# sandpaper to polish the surface of the connection surface of the base material 1 and base material 3 3 to remove oil and impurities on the surface, and then immerse in absolute ethanol solution for ultrasonic cleaning for 3-5 minutes.

[0074] Ⅱ. Place the base material 33 on the lower layer, the base material 1 on the upper layer and the middle layer 22 in the middle to form a sandwich structure, the base material 1 and the base material 3 3 are placed horizontally and laterally. The base material 1 used above is a chip, the chip material is Si, SiC, GaN, InP or GaAs, the coating metal on the back of the chip is Ni, and the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com