Processing method of composite slow-wave tube shell

A processing method and wave tube technology are applied in the field of Ku-band traveling wave tube composite slow-wave tube shell processing, which can solve the problems of complex shape and structure, incompatibility with composite tube shell processing, etc., and achieve the effect of precise processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

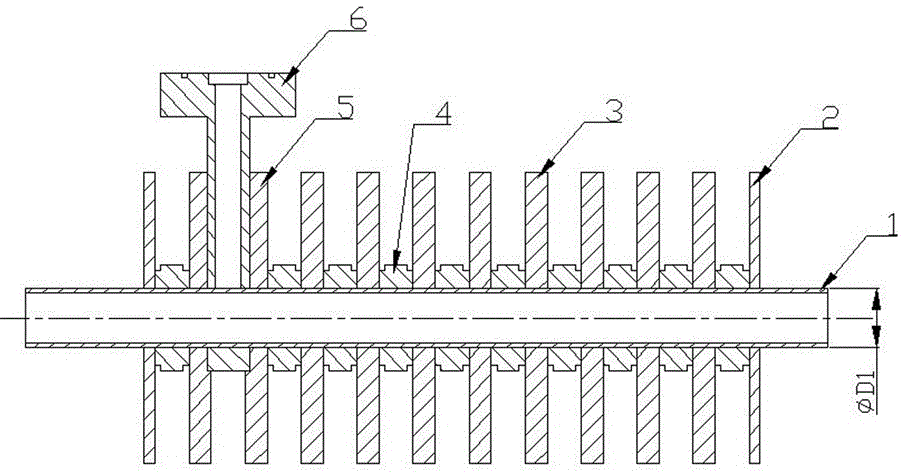

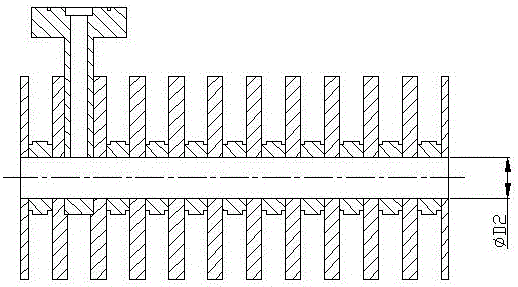

[0027] as attached figure 1 , 2 Shown: 1. Weld the docking pole piece 2, pole piece 3, inter-ring 4, adapter pole piece 5 and adapter 6 on the positioning core rod 1 according to the design drawings, so as to be used for positioning when welding the composite slow-wave tube shell The outer diameter ФD1 of the core rod 1 is used as the positioning reference to form the size of the inner hole processing channel, so as to realize the unification of the assembly reference and the processing reference, thereby improving the concentricity between the processed inner hole channel and the reference.

[0028] 2. The inner hole channel is processed by wire cutting machine. The slow wire cutting process specification is: slow wire diameter 0.07mm, wire material molybdenum wire, and feed speed 0.002mm / s; in order to improve the inner surface roughness and straight line of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com