Preparation method of green and environment-friendly composite floor base material

A composite floor, green and environmental protection technology, applied in the manufacture of veneer, manufacturing tools, wood treatment and other directions, can solve the problems of poor performance of composite floor substrate, limited promotion of composite floor, rough production process, etc. , the promotion value is high, the effect of improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

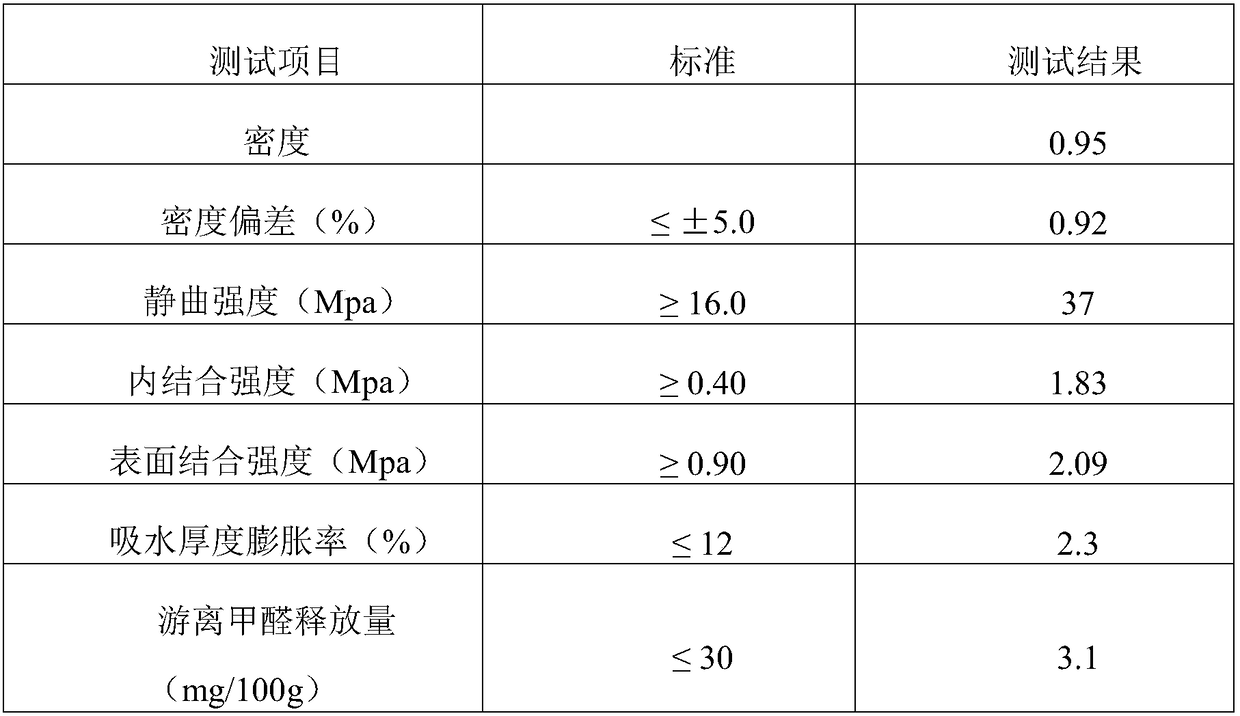

Examples

Embodiment 1

[0038] A preparation method of a green and environment-friendly composite floor substrate, which comprises the following steps:

[0039] Step 1. Select the early wood and late wood of Chinese fir with similar density, send the early wood and late wood to the chipper for cutting, and then transport them to the vibrating screen to screen out multiple pieces with a length of 16mm, a width of 15mm, and a thickness of 3mm. The wood chips obtained from the early wood are the first raw material, and the wood chips obtained from the late wood are the second raw material; the first raw material and the second raw material are respectively washed and air-washed in sequence;

[0040] Step 2, stacking the first raw material and the second raw material in a dry and ventilated place respectively, forming a first stack and a second stack, and sending them to the first stack and the second stack respectively Pass the first hot air and the second hot air into the stack, control the temperature...

Embodiment 2

[0056] A preparation method of a green and environment-friendly composite floor substrate, which comprises the following steps:

[0057] Step 1. Select the early wood and late wood of Chinese fir with similar density respectively, send the early wood and late wood to the chipper for cutting, and then transport them to the vibrating screen to screen out multiple pieces with a length of 30mm, a width of 25mm and a thickness of 5mm. The wood chips obtained from the early wood are the first raw material, and the wood chips obtained from the late wood are the second raw material; the first raw material and the second raw material are respectively washed and air-washed in sequence;

[0058] Step 2, stacking the first raw material and the second raw material in a dry and ventilated place respectively, forming a first stack and a second stack, and sending them to the first stack and the second stack respectively Pass the first hot air and the second hot air into the stack, control the...

Embodiment 3

[0074] A preparation method of a green and environment-friendly composite floor substrate, which comprises the following steps:

[0075] Step 1. Select the early wood and late wood of cork pine with similar density respectively, send the early wood and late wood to the chipper for cutting, and then transport them to the vibrating screen to screen out a plurality of 24mm long, 20mm wide, thick 4mm wood chips, the wood chips obtained from the early wood are the first raw material, and the wood chips obtained from the late wood are the second raw material; the first raw material and the second raw material are respectively washed and air-washed successively;

[0076] Step 2, stacking the first raw material and the second raw material in a dry and ventilated place respectively, forming a first stack and a second stack, and sending them to the first stack and the second stack respectively Pass the first hot air and the second hot air into the stack, control the temperature in the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com