Method and device of producing phosphoric acid through reaction of SO2 and phosphoric ore pulp

A phosphate rock slurry and SO2 technology, applied in the field of phosphorus chemical industry, can solve the problems of bronchopneumonia, asthmatic bronchitis, huge consumption of manpower and material resources, and great pollution of the surrounding environment, so as to save labor and equipment costs and facilitate operation , The effect that the process conditions are easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

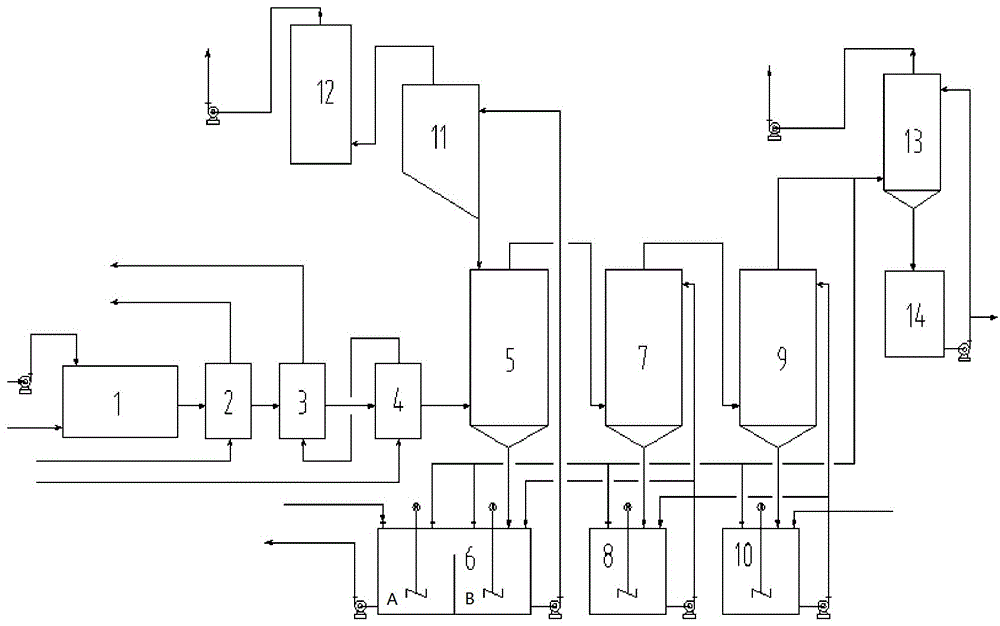

Embodiment 1

[0040] Implementation 1: The solid sulfur is turned into liquid sulfur through the rapid sulfur melting tank, and then pumped into the sulfur incinerator through the sulfur pump to fully react with the air blown by the main fan in the sulfur incinerator, and the reaction temperature is controlled at 1000°C to generate SO 2 The mixed gas with a mass concentration of 10% passes through the waste heat boiler and cools down to 450°C, then cools down to 100°C through the low-temperature boiler and heat exchanger, and then enters the primary reaction tower and the phosphate rock slurry in the primary circulating reaction tank from the lower part for gasification. Liquid countercurrent reaction, the reacted slurry enters the flash chamber, the vacuum degree is controlled to -0.05Mpa, the temperature is lowered to 85°C, and the gas enters from the lower part of the secondary reaction tower to perform countercurrent reaction with the slurry in the secondary circulating reaction tank. Th...

Embodiment 2

[0042] Implementation 2: The solid sulfur is turned into liquid sulfur through the rapid sulfur melting tank, and then pumped into the sulfur incinerator through the sulfur pump to fully react with the air blown by the main fan in the sulfur incinerator. The reaction temperature is controlled at 900°C to generate SO 2 The mixed gas with a concentration of 15% passes through the waste heat boiler, cools down to 400°C, then cools down to 80°C through the low-temperature boiler and heat exchanger, and then enters the primary reaction tower and the phosphate slurry in the primary circulating reaction tank from the lower part for gas-liquid Countercurrent reaction, the reacted slurry enters the flash chamber, the vacuum degree is controlled to -0.05Mpa, the temperature is lowered to 85°C, and the gas enters from the lower part of the secondary reaction tower to perform countercurrent reaction with the slurry in the secondary circulating reaction tank to control the reaction The temp...

Embodiment 3

[0044] Implementation 3: The solid sulfur is turned into liquid sulfur through the rapid sulfur melting tank, and then pumped into the sulfur incinerator through the sulfur pump to fully react with the air blown by the main fan in the sulfur incinerator, and the reaction temperature is controlled at 1000°C to generate SO 2 The mixed gas with a concentration of 15% passes through the waste heat boiler, cools down to 450°C, then cools down to 100°C through the low-temperature boiler and heat exchanger, and then enters the primary reaction tower and the phosphate rock slurry in the primary circulation reaction tank from the lower part for gas-liquid Countercurrent reaction, the reacted slurry enters the flash chamber, the vacuum degree is controlled to -0.06Mpa, the temperature is lowered to 80°C, and the gas enters from the lower part of the secondary reaction tower to perform countercurrent reaction with the slurry in the secondary circulating reaction tank to control the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com