High-concentration pharmaceutical wastewater treatment equipment and technology with intensified treatment of functional bacteria

A technology for enhanced treatment of pharmaceutical wastewater, applied in special compound water treatment, multi-stage water treatment, water/sewage treatment, etc. The effect of strong impact ability, good pollutant removal effect and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

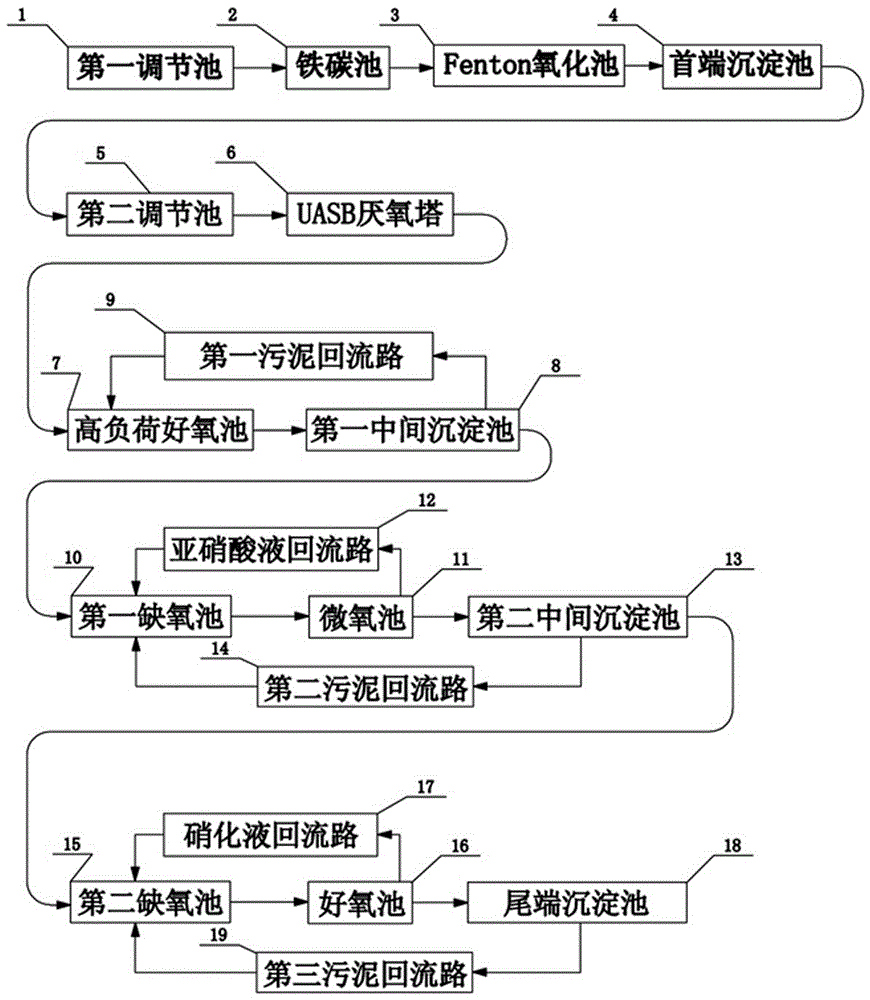

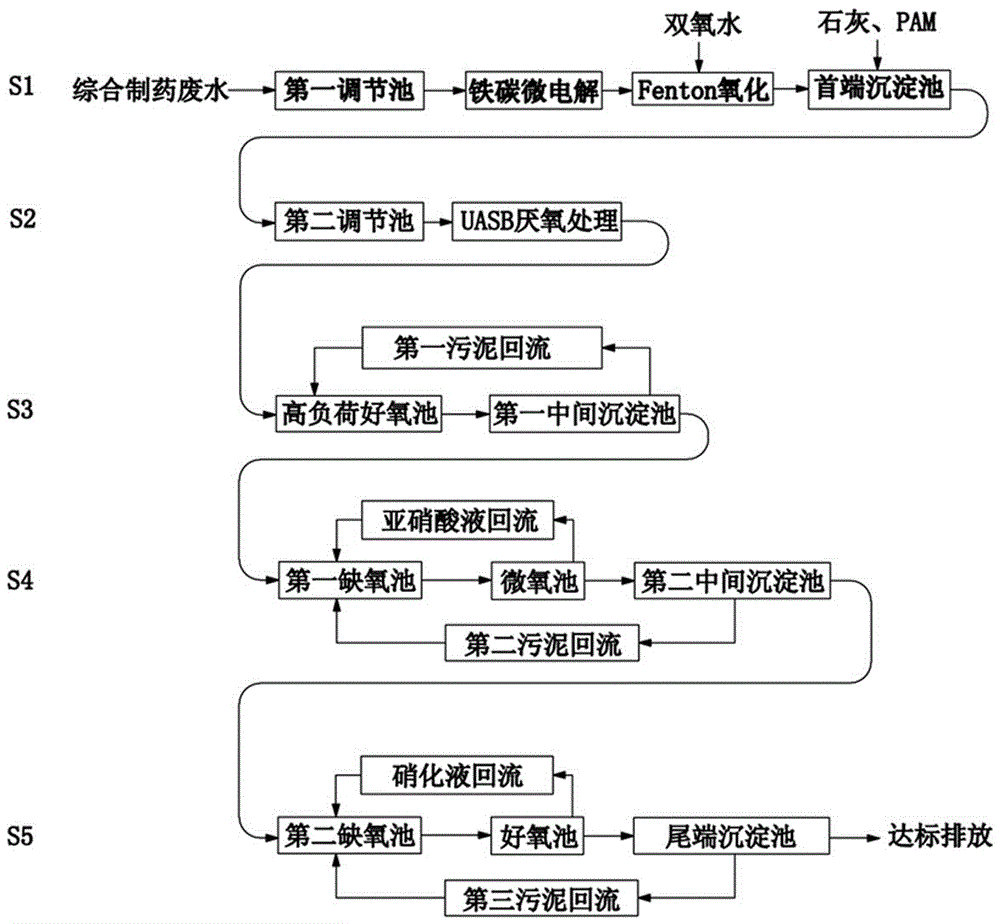

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] A high-concentration pharmaceutical wastewater treatment equipment for enhanced treatment by functional bacteria, including a physical and chemical treatment system, an anaerobic treatment system, and an aerobic treatment system.

[0035] The physical and chemical treatment system adopts the "iron-carbon micro-electrolysis + Fenton oxidation" physical and chemical method, including the first regulating pool 1, the iron-carbon pool 2, the Fenton oxidation pool 3 and the head end sedimentation pool 4;

[0036]One end of the iron-carbon pool 2 is connected to the first regulating pool 1, and the other end is connected to the Fenton oxidation pool 3; one end of the head sedimentation pool 4 is connected to the Fenton oxidation pool 3, and the other end is connected to the anaerobic treatment system.

[0037] The anaerobic treatment system adopts the "UASB ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com