Conditioning and tempering composite material for treating river and lake polluted sediment and its preparation method

A technology for polluting sediment and composite materials, applied in sludge treatment, water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, etc. The problem of poor curing effect, etc., can improve the structural properties and water characteristics, wide application range, and improve the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

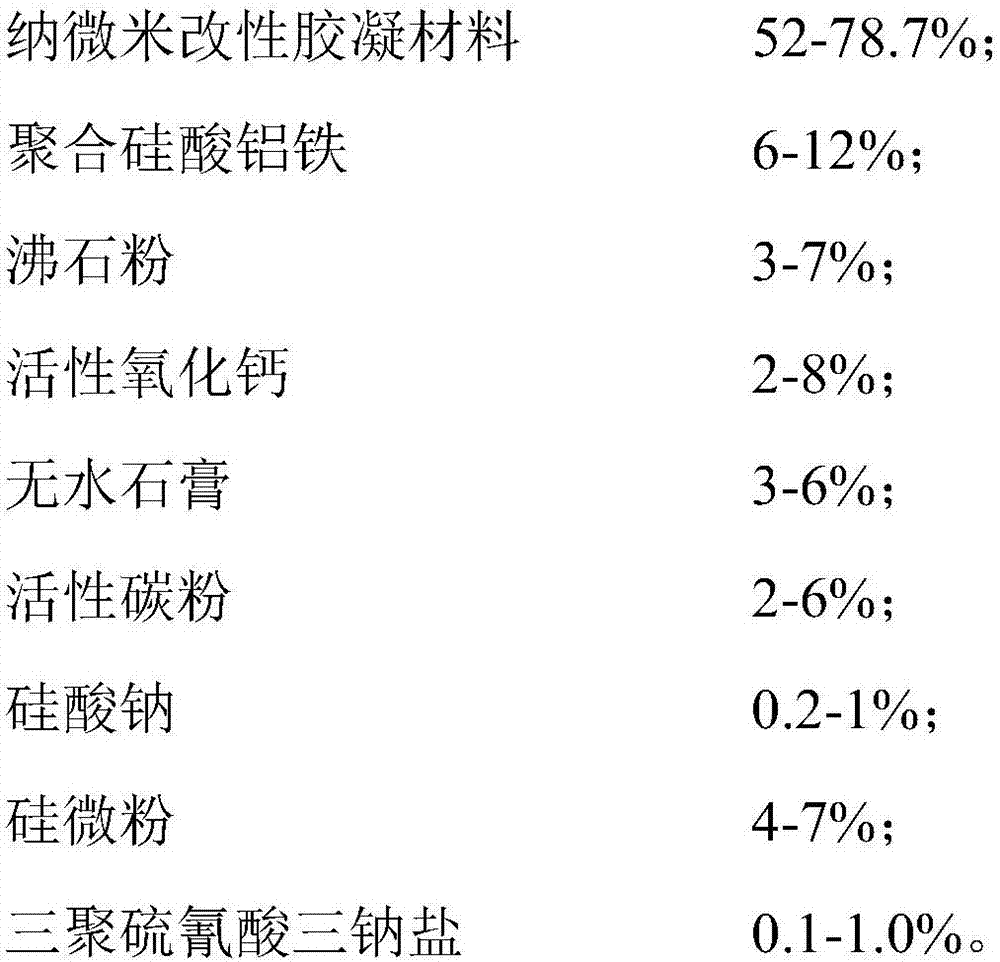

[0055] A river and lake polluted sediment treatment conditioning conditioning composite material, based on the total mass of the composite material as 100%, including each component shown in the mass percentage content of Example 1 in Table 1, wherein the The nano-micron modified gelling material is prepared by the following method:

[0056] Provides active SiO 2 40%, active Al 2 o 3 20%, active CaO 20%, active Fe 2 o 3 15%, active TiO 2 1%, active Na 2 O2%, active MgO 2%;

[0057] Mixing the above-mentioned components to form a mixed material, and calcining the mixed material at 1000-1450° C. for more than 20 minutes to obtain a sintered product;

[0058] The obtained sinter was mixed with hemihydrate CaSO 4 Mix evenly with nano-silicon dioxide at a ratio of 1:0.05:0.02, grind until D95≤15μm, and obtain nano-micron modified gelling material.

[0059] Table 1

[0060]

[0061]

[0062] Add the conditioning and tempering composite material for processing the ...

Embodiment 2

[0071]A river and lake polluted sediment treatment, conditioning and tempering composite material, based on the total mass of the composite material as 100%, includes each component shown in the mass percentage content in Example 2 of Table 1, wherein the The preparation method of the nano-micron modified gelling material is the same as that of Example 1.

[0072] The river and lake swell polluted sediment treatment conditioning and tempering composite material described in Example 2 is added to the lake pollution silt, and the consumption of the river and lake swell pollution silt treatment conditioning and tempering composite material is the dry weight of the polluted bottom sludge The ratio is shown in Example 2 of Table 1. After conditioning and tempering for 10-30min, enter the filter press for mud-water separation and solidification to obtain mud cake completely. The sediment before and after conditioning is tested for pollutants. The detection standard is "GB 15618-1995...

Embodiment 3

[0079] A river and lake surge polluted sediment treatment conditioning conditioning composite material, based on the total mass of the composite material as 100%, including each component shown in the mass percentage content in Example 3 of Table 1, wherein the The preparation method of the nano-micron modified gelling material is the same as that of Example 1.

[0080] The river and lake polluted sediment treatment conditioning conditioning composite material described in Example 3 is added to the sewage treatment plant contaminated sediment, and the amount of the river and lake pollution sediment treatment conditioning conditioning composite material is the polluted sediment The ratio of the dry weight is shown in Example 3 of Table 1. After conditioning and tempering for 10-30 minutes, the mixture is put into a filter press for mud-water separation and solidification to obtain a mud cake. The sediment before conditioning was tested for pollutants and microorganisms. The tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com