2,4-dinitrophenol surface molecular imprinting polymer and preparing method and application thereof

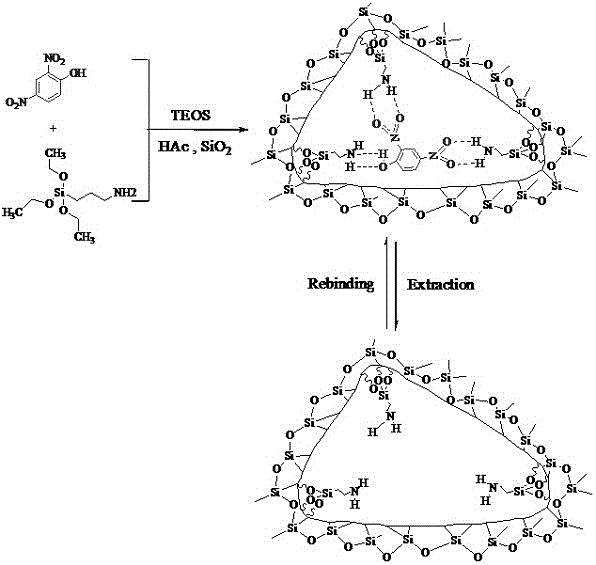

A technology of surface molecular imprinting and dinitrophenol, which is applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of complex preparation process, cumbersome post-treatment of polymers, and restrictions on the application of molecularly imprinted polymer materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] With 20mL absolute ethanol as solvent, 0.2g activated silica gel as carrier, 0.037g 2,4-dinitrophenol as template molecule, 3-aminopropyltriethoxysilane as functional monomer, tetraethylorthosilicate As a cross-linking agent (the molar ratio of 2,4-dinitrophenol, 3-aminopropyltriethoxysilane and tetraethylorthosilicate is 1:2:10), 0.5mL glacial acetic acid (1mol / L) as the initiator, shaking in a water bath at 30°C for 9 hours, and extracting the obtained product with a mixed solution of methanol / acetic acid with a volume ratio of 9 / 1 for 48 hours, then washing with methanol and drying in vacuo at 60°C to obtain Molecularly imprinted polymers on the surface of 2,4-dinitrophenol.

Embodiment 2

[0020] With 20mL absolute ethanol as solvent, 0.2g activated silica gel as carrier, 0.037g 2,4-dinitrophenol as template molecule, 3-aminopropyltriethoxysilane as functional monomer, tetraethylorthosilicate As a crosslinking agent (the molar ratio of 2,4-dinitrophenol, 3-aminopropyltriethoxysilane and tetraethylorthosilicate is 1:6:20), 0.5mL glacial acetic acid (1mol / L) as the initiator, shake in a water bath at 30°C for 30h, shake and elute the obtained product with a mixed solution of methanol / acetic acid with a volume ratio of 9 / 1 for 5 times (1h / time), and wash with methanol Vacuum-dried at 60°C to obtain 2,4-dinitrophenol surface molecularly imprinted polymer.

Embodiment 3

[0022] With 20mL absolute ethanol as solvent, 0.2g activated silica gel as carrier, 0.037g 2,4-dinitrophenol as template molecule, 3-aminopropyltriethoxysilane as functional monomer, tetraethylorthosilicate As a crosslinking agent (the molar ratio of 2,4-dinitrophenol, 3-aminopropyltriethoxysilane and tetraethylorthosilicate is 1:12:35), 0.5mL glacial acetic acid (1mol / L) as the initiator, shaking in a water bath at 30°C for 16 hours, and extracting the obtained product with a mixed solution of methanol / acetic acid with a volume ratio of 9 / 1 for 48 hours, then washing with methanol and drying in vacuo at 60°C to obtain Molecularly imprinted polymers on the surface of 2,4-dinitrophenol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com