PA66/tremolite/MBS composite material and preparing method thereof

A composite material, PA66 technology, applied in the field of PA66/tremolite/MBS composite material and its preparation, can solve the problems of reducing material toughness and rigidity, and achieve a blending performance with strong complementarity and excellent processing technology Effect

Inactive Publication Date: 2017-01-04

上海聚威新材料股份有限公司

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, studies have shown that when rigid particles are added to PA66, the toughness of the material is generally reduced while increasing the rigidity of the material. The higher the filling amount, the more significant the effect; Increased toughness, improved low-temperature impact performance, but reduced the rigidity of the material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

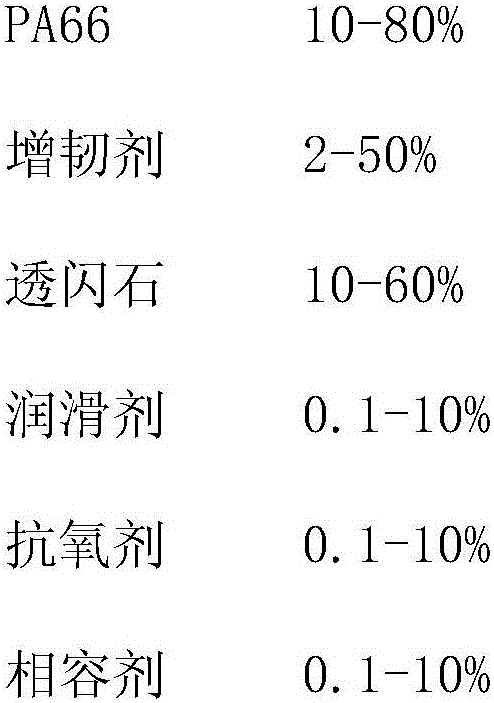

[0025] A kind of PA66 / tremolite / MBS composite material and preparation method thereof provided by the present invention, adopt PA66, toughening agent, tremolite, lubricant, antioxidant, compatibilizer to prepare low-cost high-performance engineering plastic alloy ;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a PA66 / tremolite / MBS composite material and a preparing method thereof. PA66, a toughening agent, tremolite, a lubricating agent, antioxidant and compatilizer are prepared into low-cost high-performance engineering plastic alloy. Methyl methacrylate-butadiene-styrol copolymer (MBS) is adopted to carry out toughening modification research on PA 66, the copolymer is the toughening agent of a core-shell structure, and bisphenol A type epoxy resin (DGEBA) is used as a bulking agent. The PA66 / tremolite / MBS composite material is high in mixing performance complementarity and processing process, and a PA66 / tremolite / MBS alloy product excellent in comprehensive performance can be obtained through blending, screw extruding and injection molding.

Description

technical field [0001] The invention relates to a PA66 / tremolite / MBS composite material and a preparation method thereof. Background technique [0002] PA66 is a crystalline polymer. As an engineering plastic, it has excellent comprehensive properties and is widely used in automobiles, electronics, electrical equipment, mechanical parts, and transportation equipment. However, the heat resistance and acid resistance of PA66 are poor, and the impact strength is low in dry state and low temperature; the water absorption rate and molding shrinkage rate are relatively large, which affects the dimensional stability and electrical properties of the product. In order to be suitable for the development of polyamide in different fields, this requires polyamide to have higher mechanical strength and heat resistance. Mechanical parts and polyamide for railway locomotives all put forward high requirements on the mechanical properties and dimensional stability of PA66. Therefore, the mo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L77/06C08L51/04C08L63/00C08K9/06C08K3/34

CPCC08L77/06C08L51/04C08L2205/03C08L63/00C08K9/06C08K3/34

Inventor 王晶张天荣王俊刘志林

Owner 上海聚威新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com