Anti-bacterial wood-plastic composite section material and preparation method thereof

A composite profile and wood-plastic technology, applied in the field of building materials, can solve problems such as the disappearance of antibacterial and antiseptic effects, and achieve the effects of shortening the preparation cycle, improving overall quality, and superior mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

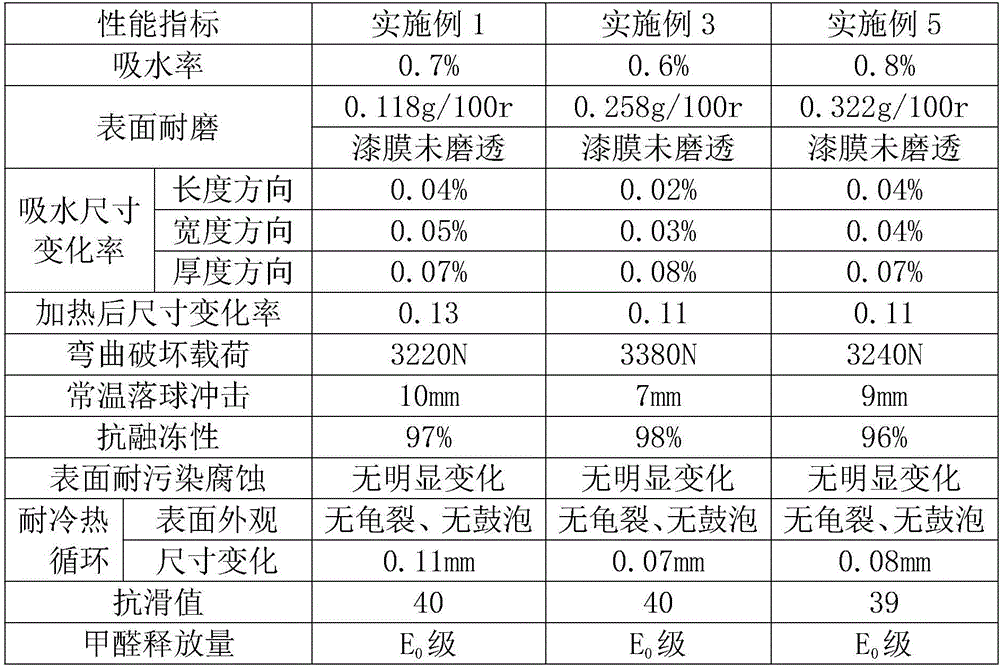

Examples

Embodiment 1

[0023] The antibacterial wood-plastic composite profile is made of the following raw materials in parts by weight: 60 parts of corn stalk powder (120 mesh in particle size), 26 parts of polypropylene (110 mesh in particle size), 20 parts of walnut shell powder, 12 parts of phenylurea, 5 parts of p-diethylaminopyridine, 8 parts of 8-hydroxyquinoline copper, 4 parts of glyceryl dimethacrylate, 7 parts of diethylene glycol dibenzoate, 3 parts of toluene diphenyl phosphate , 7 parts of tetramethyldivinyl disiloxane, 1 part of isocyanate propyltriethoxysilane, 2 parts of 1,3-dimethyl-6-aminouracil, 8 parts of 1-formyl imidazole, isocyanate 1 part of thiazolone, 1 part of dialkyl diphenylamine.

[0024] The preparation method of antibacterial wood-plastic composite profiles comprises the following preparation steps: put corn stalk powder and walnut shell powder into a mixer, heat at 80°C for 8 minutes, and then add 1-formyl imidazole, 8-hydroxyquinoline copper, Glyceryl dimethacryl...

Embodiment 2

[0026] The antibacterial wood-plastic composite profile is made of the following raw materials in parts by weight: 50 parts of corn stalk powder (130 mesh in particle size), 22 parts of polypropylene (120 mesh in particle size), 25 parts of walnut shell powder, 10 parts of phenylurea, 6 parts of p-diethylaminopyridine, 7 parts of 8-hydroxyquinoline copper, 5 parts of glyceryl dimethacrylate, 6 parts of diethylene glycol dibenzoate, 4 parts of toluene diphenyl phosphate , 6 parts of tetramethyldivinyldisiloxane, 2 parts of isocyanate propyltriethoxysilane, 3 parts of 1,3-dimethyl-6-aminouracil, 6 parts of 1-formyl imidazole, iso 2 parts of thiazolone, 2 parts of dialkyl diphenylamine.

[0027]The preparation method of the antibacterial wood-plastic composite profile comprises the following preparation steps: putting corn stalk powder and walnut shell powder into a mixer, heating at 85° C. for 5 minutes, and then sequentially adding 1-formyl imidazole, 8-hydroxyquinoline copper,...

Embodiment 3

[0029] The antibacterial wood-plastic composite profile is made of the following raw materials in parts by weight: 40 parts of corn stalk powder (140 mesh in particle size), 18 parts of polypropylene (130 mesh in particle size), 30 parts of walnut shell powder, 8 parts of phenylurea, 8 parts of p-diethylaminopyridine, 5 parts of 8-hydroxyquinoline copper, 6 parts of glyceryl dimethacrylate, 5 parts of diethylene glycol dibenzoate, 5 parts of toluene diphenyl phosphate , 5 parts of tetramethyldivinyldisiloxane, 3 parts of isocyanate propyltriethoxysilane, 5 parts of 1,3-dimethyl-6-aminouracil, 5 parts of 1-formyl imidazole, iso Thiazolone 3 parts, dialkyl diphenylamine 3 parts.

[0030] The preparation method of antibacterial wood-plastic composite profiles comprises the following preparation steps: put corn stalk powder and walnut shell powder into a mixer, heat at 90°C for 6 minutes, and then add 1-formyl imidazole, 8-hydroxyquinoline copper, Glyceryl dimethacrylate, dialkyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com