An acid liquid system for acidifying carbonate rock reservoirs

A carbonate rock reservoir and acid solution technology, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of difficult to achieve deep acidification of carbonate rock reservoirs and shorten the service life of downhole pipe strings and equipment. Shortage, increased corrosion of downhole pipe strings and equipment, etc., to achieve the effect of being conducive to large-scale on-site construction application, convenient transportation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

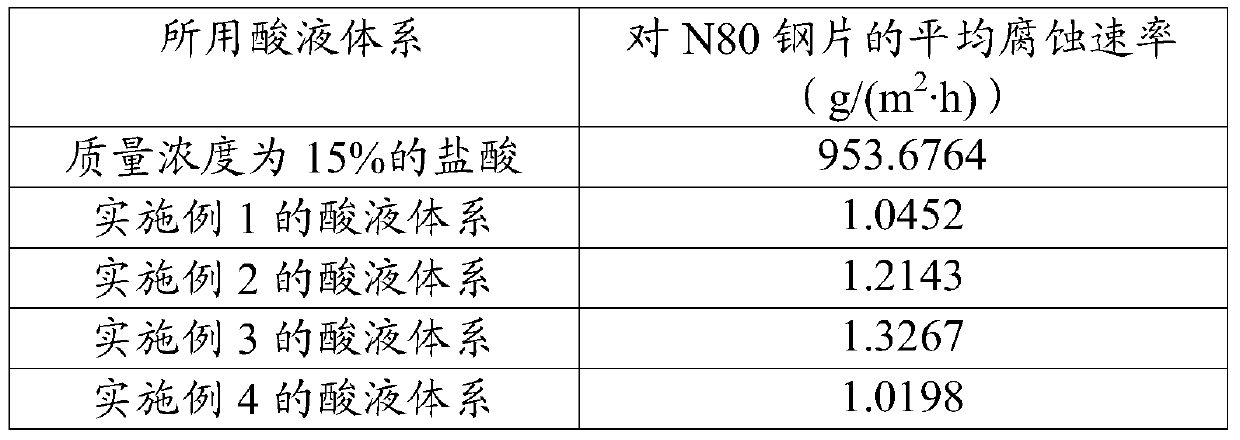

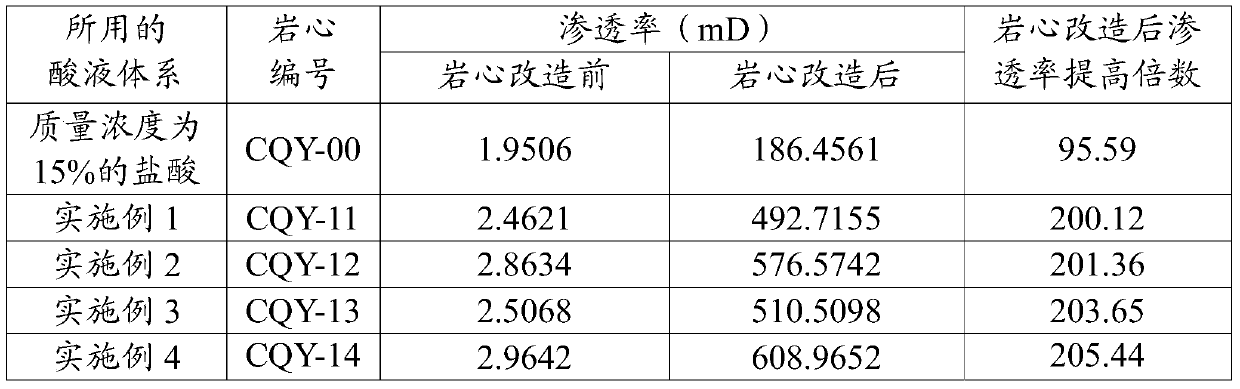

Embodiment 1

[0028] This embodiment provides an acid liquid system for acidifying carbonate rock reservoirs, which includes the following components in mass percentage: 19.8% sulfamic acid, 15.0% urea nitrate, 7.0% formic acid, 0.5% potassium chloride, 2.0% ethanol, 0.5% imidazoline corrosion inhibitor and the balance of water.

[0029] The preparation method of this acid liquid system is as follows:

[0030] According to the mass percentage content of each component in the acid liquid system, first put sulfamic acid, urea nitrate, potassium chloride, and ethanol in the reactor at room temperature and stir for 10 minutes, and then add formic acid, imidazoline The corrosion inhibitor and water are stirred evenly to obtain the acid solution system of this embodiment.

Embodiment 2

[0032] This embodiment provides an acid liquid system for acidifying carbonate rock reservoirs, which includes the following components in mass percentage: 21.0% sulfamic acid, 20.0% urea nitrate, 8.0% acetic acid, 1.5% sodium chloride, 2.0% crude oil, 0.6% thiourea corrosion inhibitor and the rest water.

[0033] The preparation method of this acid liquid system is as follows:

[0034] According to the mass percentage content of each component in the acid liquid system, first put sulfamic acid, urea nitrate, sodium chloride, and crude oil in the reaction kettle and stir for 10 minutes at room temperature, and then add acetic acid and thiourea to the reaction kettle The corrosion inhibitor and water are stirred evenly to obtain the acid solution system of this embodiment.

Embodiment 3

[0036] This embodiment provides an acid liquid system for acidifying carbonate rock reservoirs, which includes the following components in mass percentage: 22.5% sulfamic acid, 16.0% urea nitrate, 5.5% acetic acid, 1.0% sodium chloride, 3.0% diesel oil, 0.8% imidazoline corrosion inhibitor and the rest water.

[0037] The preparation method of this acid liquid system is as follows:

[0038] According to the mass percentage content of each component in the acid liquid system, first put sulfamic acid, urea nitrate, sodium chloride, and diesel oil in the reactor at room temperature and stir for 10 minutes, and then add acetic acid, imidazoline The corrosion inhibitor and water are stirred evenly to obtain the acid solution system of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com