Method for producing organic fertilizers special for tobacco by using earthworms processing cow manure

A technology of organic fertilizer and cow dung, applied in the field of tobacco fertilizer, can solve the problems of high fertilizer cost, large fertilizer efficiency loss and long composting time for tobacco farmers, and achieves rich content of available nutrients, high fertilizer uniformity and high decay rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

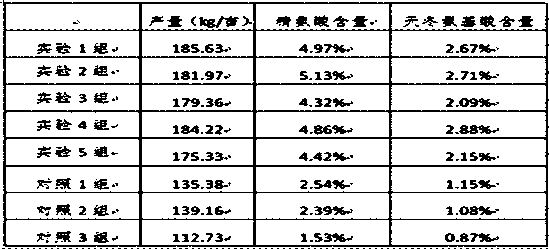

Examples

Embodiment 1

[0019] A method for utilizing earthworms to process cow dung to produce tobacco-specific organic fertilizer, comprising the following steps:

[0020] S1. Ingredients: Mix 88 parts of alfalfa, 70 parts of clover, and 50 parts of corn grass, pulverize it into powder with a particle size of 1 cm, stir the powder evenly with a nutrient solution of 0.3 times its mass, soak it at 40°C for 30 minutes, and then add 30 parts of it Corn cob powder, 200 parts of fresh cow dung, 10 parts of urea, 10 parts of potassium dihydrogen phosphate, 3 parts of ferrous sulfate, 8 parts of zinc sulfate, and 20-30 parts of bone meal are evenly stirred to obtain a base material; wherein, the nutrient solution The preparation method is as follows: mix 3 parts of nitric acid, 0.5 part of calcium chloride, 0.8 part of magnesium chloride, 4 parts of starch and 100 parts of clear water;

[0021] S2. Activation of raw materials: in the environment of temperature 30°C and humidity 55%, inoculate the base mate...

Embodiment 2

[0024] A method for utilizing earthworms to process cow dung to produce tobacco-specific organic fertilizer, comprising the following steps:

[0025] S1. Ingredients: Mix 120 parts of alfalfa, 90 parts of clover, and 80 parts of corn grass, pulverize it into powder with a particle size of 1.5cm, stir the powder evenly with a nutrient solution of 0.5 times its mass, soak it at 45°C for 50 minutes, and then add 50 Parts of corncob powder, 300 parts of fresh cow dung, 20 parts of urea, 15 parts of potassium dihydrogen phosphate, 8 parts of ferrous sulfate, 10 parts of zinc sulfate, and 30 parts of bone meal were stirred to obtain a base material; The preparation method is as follows: mix 5 parts of nitric acid, 1 part of calcium chloride, 1.3 parts of magnesium chloride, 5 parts of starch and 130 parts of water;

[0026] S2. Activation of raw materials: in the environment of temperature 35 ℃ and humidity 65%, inoculate the base material with 5% of its mass of composite microorgan...

Embodiment 3

[0029] A method for utilizing earthworms to process cow dung to produce tobacco-specific organic fertilizer, comprising the following steps:

[0030] S1. Ingredients: Mix 90 parts of alfalfa, 80 parts of clover, and 70 parts of corn grass, pulverize it into a powder with a particle size of 1 cm, stir the powder evenly with a nutrient solution of 0.5 times its mass, soak it at 45°C for 30 minutes, and then add 50 parts of it Corn cob powder, 200 parts of fresh cow dung, 20 parts of urea, 10 parts of potassium dihydrogen phosphate, 8 parts of ferrous sulfate, 8 parts of zinc sulfate, and 30 parts of bone meal are stirred to obtain a base material; wherein, the preparation of the nutrient solution The method is: mix 3 parts of nitric acid, 1 part of calcium chloride, 0.8 part of magnesium chloride, 5 parts of starch, and 100 parts of water;

[0031] S2. Activation of raw materials: in an environment of temperature 35°C and humidity 55%, inoculate the base material with compound m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com