Clean foaming fracturing fluid and preparation method thereof

A technology of cleaning foam and fracturing fluid, which is applied in the field of hydraulic fracturing, can solve problems such as inaccurate fracture data, and achieve the effect of simple and feasible method, low damage and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

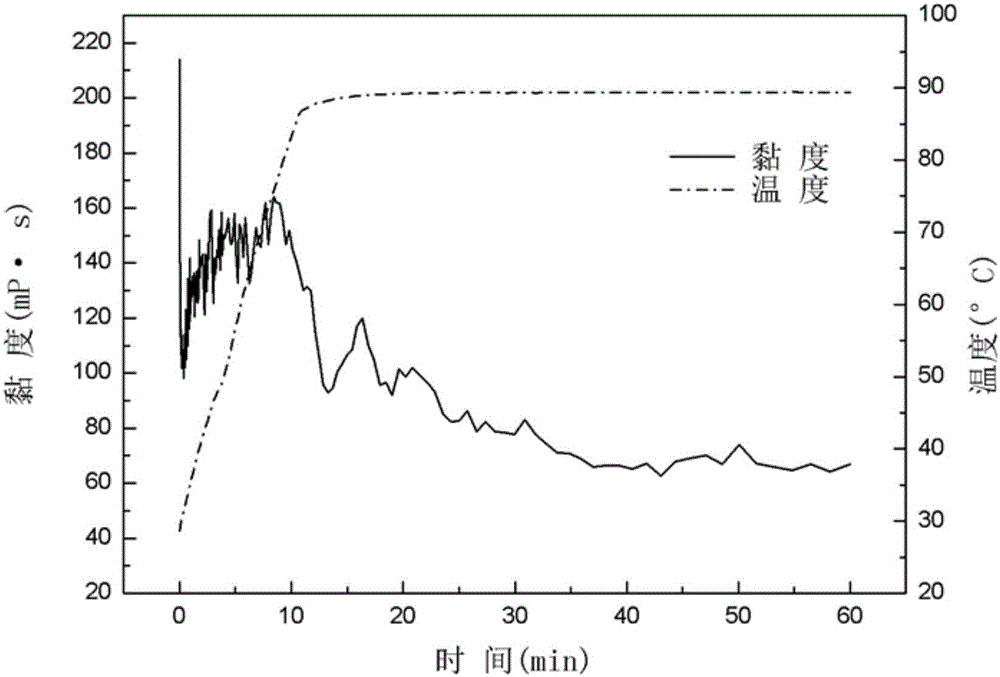

[0026] The preparation method of the above-mentioned clean foam fracturing fluid comprises the following steps:

[0027] In terms of mass percentage, 0.8% to 1.2% of magnetic nanoparticle dispersion, 0.8% to 1.2% of foaming agent and 3% to 5% of surfactant are added to 92.6% to 95.4% of the first solvent, and Stir to get this clean foam fracturing fluid. Specifically, the first solvent is water. When preparing clean foam fracturing fluid, you only need to add the three substances into the water and stir well. In a preferred embodiment of the present invention, the stirring speed is 5000r / min-10000r / min, and the stirring time is 1min-3min, so as to ensure sufficient foaming of the clean fracturing fluid. The proportion of the clean foam fracturing fluid affects the foam quality of the clean foam fracturing fluid.

[0028] In this embodiment, preferably, during the fracturing operation at the well site, nitrogen is preferably used as the accompanying gas, and the clean foam f...

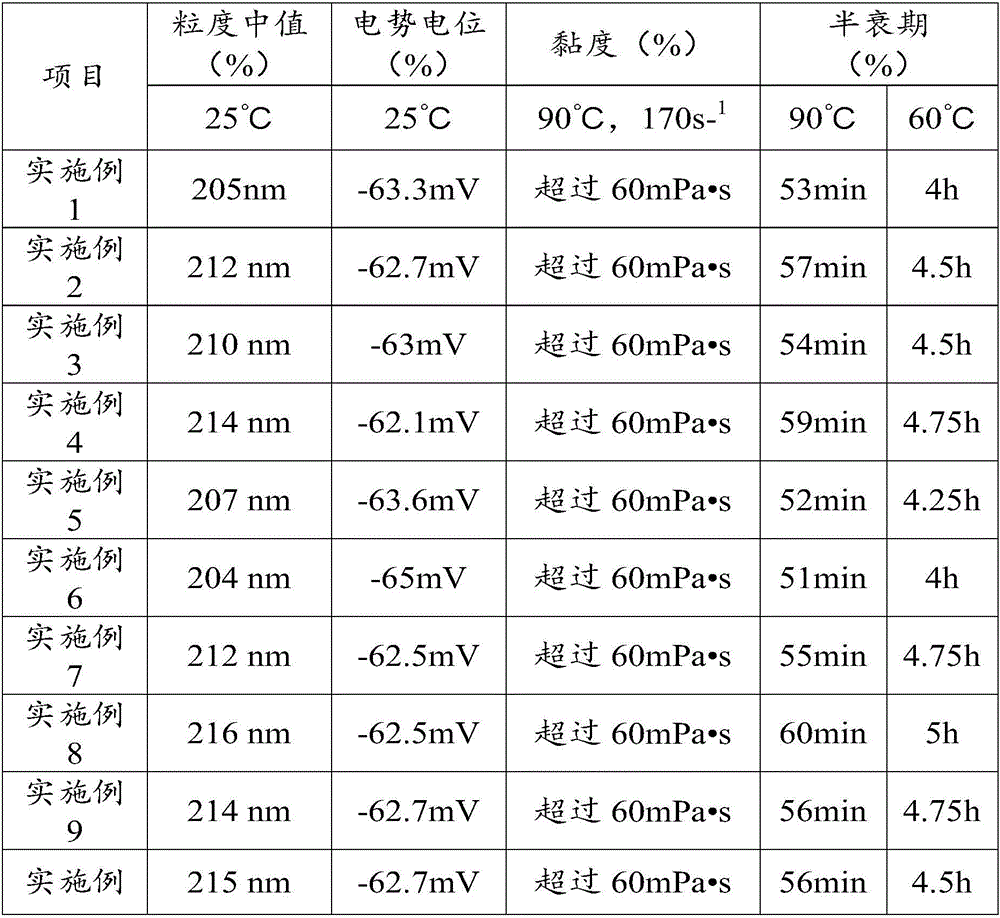

Embodiment 1

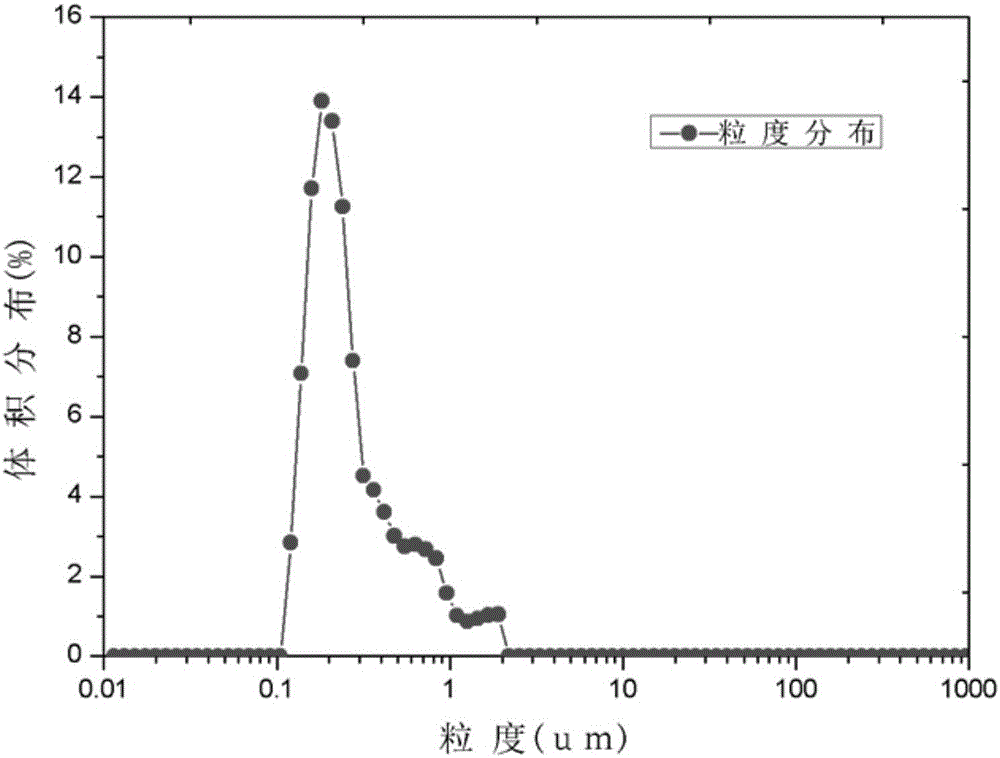

[0032]Under mechanical stirring condition, add 0.125g citric acid to 100ml deionized water to obtain citric acid solution, add 2.15g ferrous chloride tetrahydrate and 4.05g ferric chloride hexahydrate in the citric acid solution to obtain the first solution, heat to 90° C., 22 ml of ammonia water with a mass fraction of 30% was added to the first solution to obtain a second solution. Stir the second solution at 90°C for 2 hours, cool and centrifuge to separate the supernatant of the second solution from the solid-phase substance, wash the separated solid-phase substance with absolute ethanol, and then wash with water, and the washed solid-phase substance The substance is dissolved in the second solvent at a mass concentration of 8% to obtain a nanofluid, and ultrasonic dispersion is used to obtain a stable magnetic nanoparticle dispersion.

[0033] Under mechanical stirring conditions, in 100ml deionized water, add 0.8g of magnetic nanoparticle dispersion, 0.8g of sodium dodec...

Embodiment 2

[0035] Under mechanical stirring condition, add 0.125g citric acid to 100ml deionized water to obtain citric acid solution, add 2.15g ferrous chloride tetrahydrate and 4.2g ferric chloride hexahydrate in the citric acid solution to obtain the first solution, and heat to 88° C., and then add 0.125 g of citric acid to the first solution, and then add 25 ml of ammonia water with a mass fraction of 30% to the first solution to obtain a second solution. Stir the second solution at 88°C for 2.5 hours, cool and centrifuge to separate the supernatant of the second solution from the solid-phase substance, wash the separated solid-phase substance with absolute ethanol, and then wash with water, and the washed solid-phase substance The phase substance is dissolved in the second solvent at a mass concentration of 8% to obtain a nanofluid, and ultrasonic dispersion is used to obtain a stable magnetic nanoparticle dispersion.

[0036] Under mechanical stirring conditions, 0.9 g of magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com