Anti-adhesion stainless steel cutter and preparation method thereof

A stainless steel and anti-adhesion technology, which is applied to the surface coating liquid device, ion implantation plating, coating, etc., can solve the problems that ordinary stainless steel does not have antibacterial function, ordinary stainless steel has poor wear resistance, and hidden dangers to human health. Achieve the effects of avoiding heavy metal spillage, enhancing wear resistance, and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

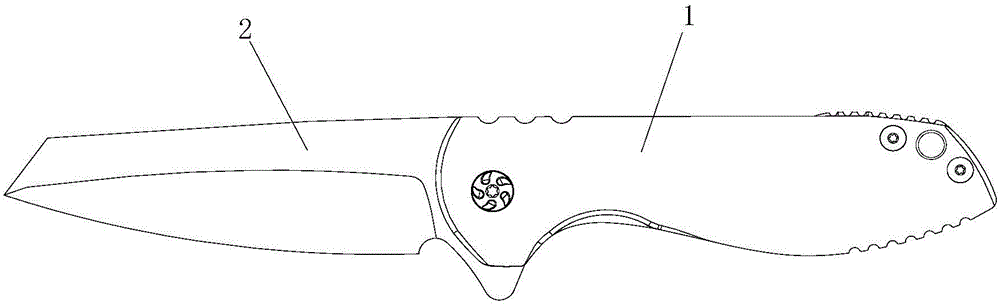

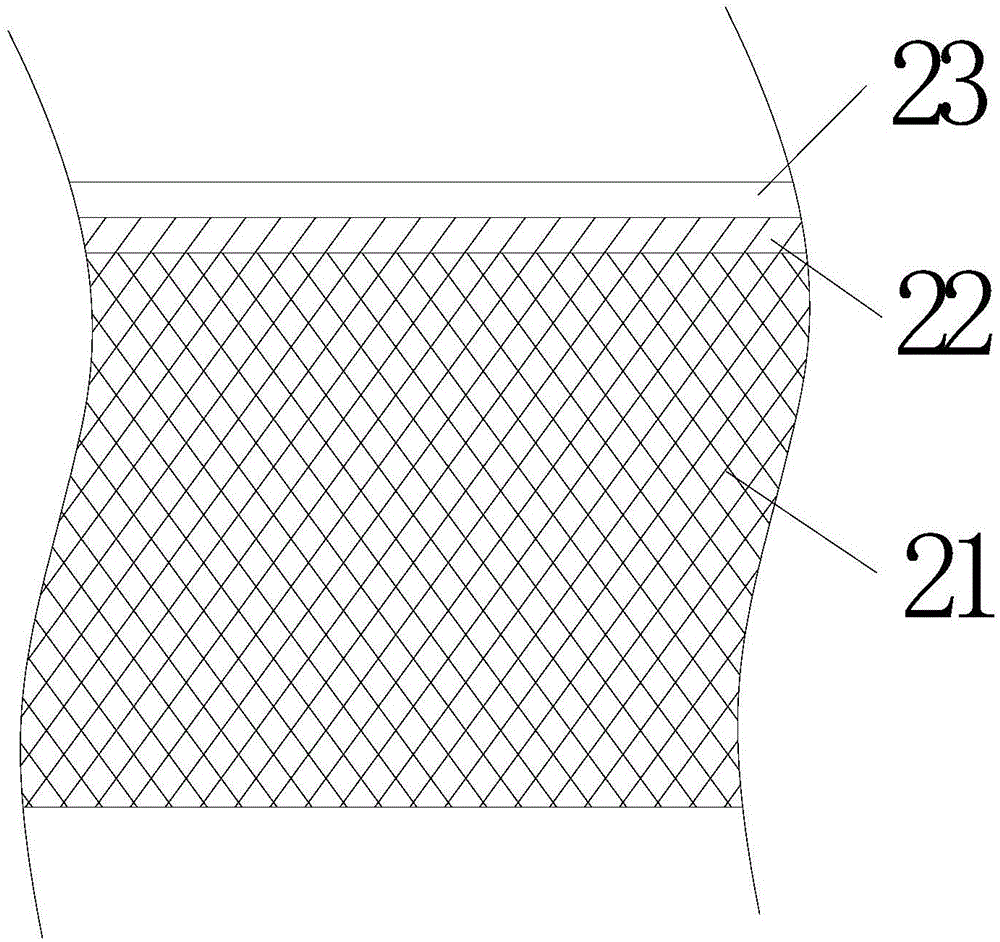

[0037] refer to Figure 1-2 , the present embodiment provides a stainless steel knife, including a handle 1 and a knife face 2, the knife face 2 includes a stainless steel substrate 21; a layer of silver thin film 22 is deposited on the outer surface of the stainless steel substrate 21 by vacuum coating method, so The outer surface of the silver film is coated with a layer of anti-adhesive layer 23. The anti-adhesive layer 23 is a Teflon anti-adhesive layer.

[0038] A preparation method of a stainless steel knife, comprising the following steps:

[0039] 1) Pre-processing:

[0040] 1-1) Impurity removal: soak the cleaned stainless steel substrate in concentrated hydrochloric acid for 20 minutes;

[0041] 1-2) Polishing treatment: the stainless steel substrate after removing impurities is soaked in a polishing solution, and the surface of the stainless steel tool is chemically polished to form a layer of iron oxide on the surface of the stainless steel substrate; the temper...

Embodiment 2

[0057] The characteristics of this embodiment are: the chemical composition of the stainless steel substrate includes the following elements by weight percentage: C: 0.34%, N: 0.20%, Si: 1.0%, Mn: 3.5%, Cr: 20.0%, Cu: 1.6% , Zn: 0.5%, Ag: 0.10%, Ni: 9.0%, Mo: 3.6%, Nb: 1.2%, Ti: 1.8%, and the balance is iron and impurities. Others are the same as in Example 1.

Embodiment 3

[0059] The characteristics of this embodiment are: the chemical composition of the stainless steel substrate includes the following elements by weight: C: 0.35%, N: 0.22%, Si: 1.1%, Mn: 3.55%, Cr: 20.5%, Cu: 1.7% , Zn: 0.55%, Ag: 0.11%, Ni: 9.05%, Mo: 3.7%, Nb: 1.3%, Ti: 1.9%, and the balance is iron and impurities. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com