Illumination system

A lighting system and light source technology, applied in the field of lighting systems, can solve the problems of reducing the service life of the shutter 40 and the coupling group 50, the workload of replacing components in the system, and the large volume of the lighting system, so as to save microlens arrays, improve service life, Effect of improving coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

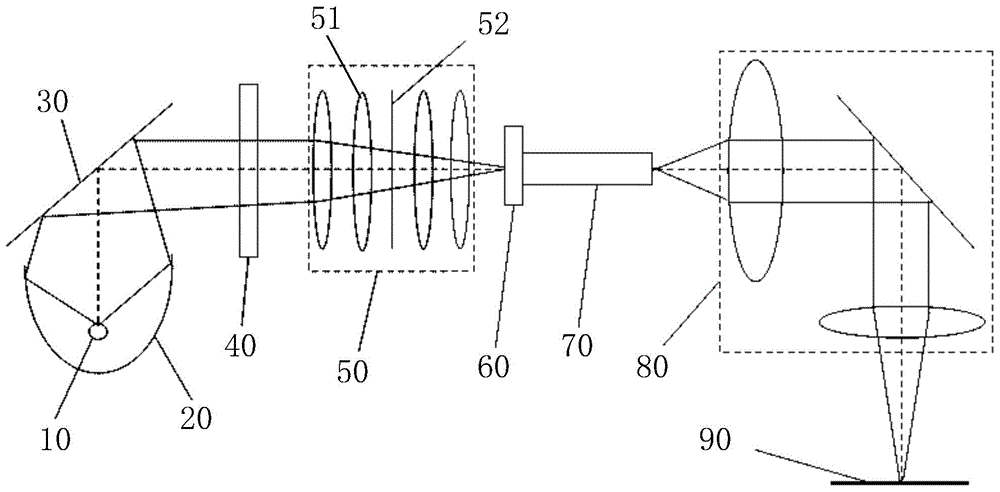

[0037] A lighting system provided by the invention, such as Figure 4 As shown, the light source 110, the filter 120, the shutter 130, the coupling group 140, the quartz rod 150, the relay group 160 and the mask surface 170 are sequentially included along the propagation direction of the light beam. In this embodiment, the light source 110 is a mercury lamp Light source 111, described mercury lamp light source 111 provides the energy source of required NA (numerical aperture) for illumination system; Also comprises ellipsoid reflective bowl 112 and cold light mirror 113 between described mercury lamp light source 111 and described filter plate 120 , the mercury lamp light source 111 is located at a focal point of the ellipsoidal reflective bowl 112, and the function of the ellipsoidal reflective bowl 112 is to gather light emitted from one focal point to another focal point; the mercury lamp light source 111 The emitted light beam is reflected by the ellipsoidal reflecting bow...

Embodiment 2

[0049] Compared with Example 1, also with Figure 4 For example, the difference of this embodiment is: when the NA of the coupling group 140 on the mask surface 170 is 0.1, please refer to Figure 10 , the radius of curvature R1=500mm of the first optical surface 143; the radius of curvature R2=-30.499mm of the second optical surface 144, the conic coefficient K=-1.211 of the second optical surface 144, the effective focal length f=64.218, and the central thickness d =45mm, outer diameter D=90mm; the aspheric lens is made of fused silica (F-SILICA), wherein the refractive index Nd=1.4585, Abbe number νd=67.79.

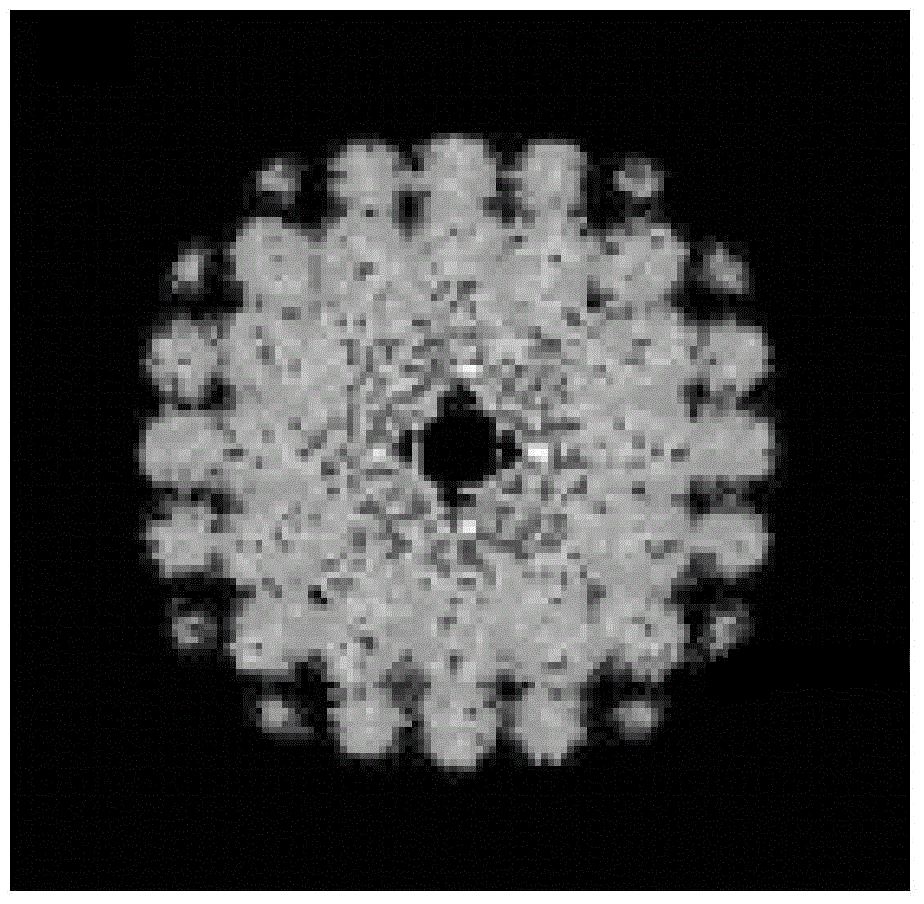

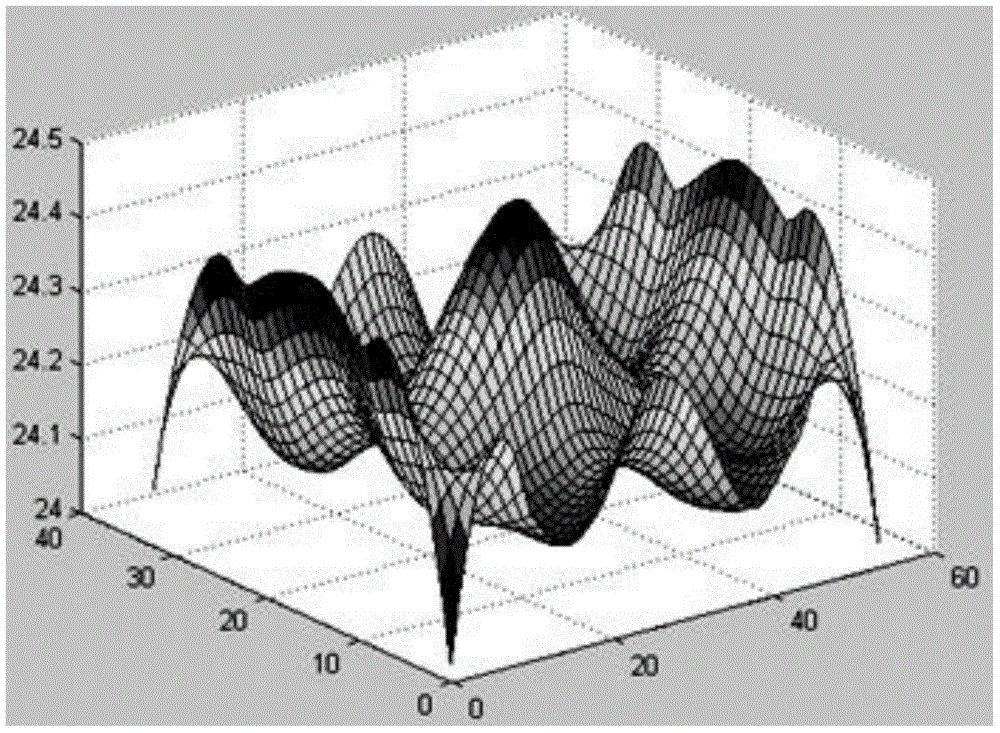

[0050] In this embodiment, the quartz rod 150 has a square structure, the end surface size is 17.2mm×17.2mm, the length is 400mm, the uniform field of view is 45mm×45mm, the input power of the light source 110 is 100W, and the energy entering the quartz rod 150 is 92.582W , the energy received on the mask surface 170 is 92.503W; the energy of uniform field of view spo...

Embodiment 3

[0053] Compared with Embodiments 1 and 2, the difference of this embodiment is that: the light source 210 is an LED light source. Please focus on reference Figure 11 , the light beam emitted by the LED light source 210 is filtered by the filter 220, and then incident on the coupling group 240 through the shutter 230, and the light beam coupled by the aspheric lens in the coupling group 240 passes through the quartz rod 250 for more than The light is incident to the relay group 260 after being homogenized after the second reflection, and is imaged on the mask surface 270 after being enlarged by the relay group 260 .

[0054] The lighting system provided by this embodiment also has the advantages of high coupling efficiency, small size, low cost, and prolongs the service life of the shutter 230 and the coupling group 240 .

[0055] In summary, an illumination system provided by the present invention sequentially includes a light source, a filter, a shutter, a coupling group, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com