Lithium battery separator and manufacturing method thereof

A manufacturing method and technology of lithium batteries, applied in the direction of separators/films/diaphragms/spacers, circuits, electrical components, etc., can solve the problems of flammability, explosion, and low safety performance of plastic separators, and achieve low cost , good effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

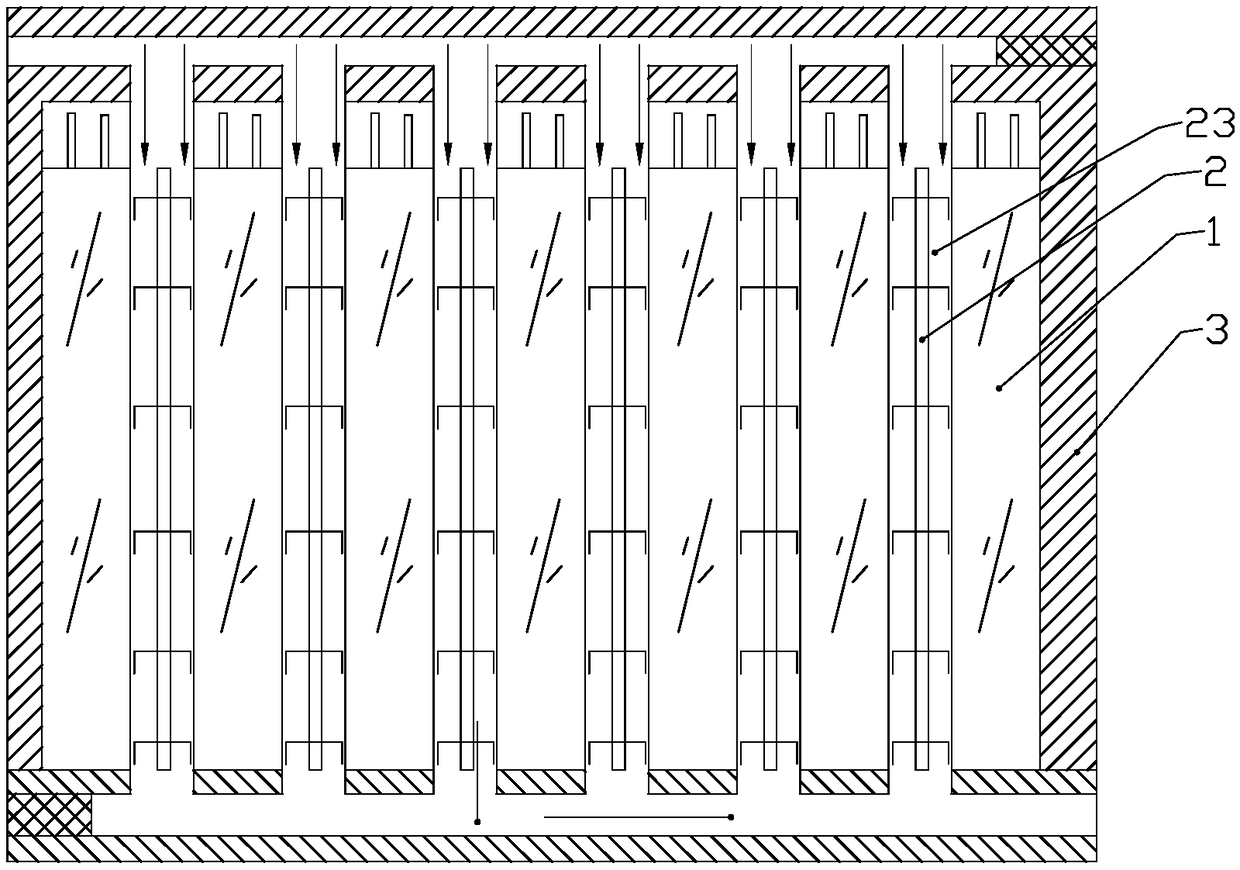

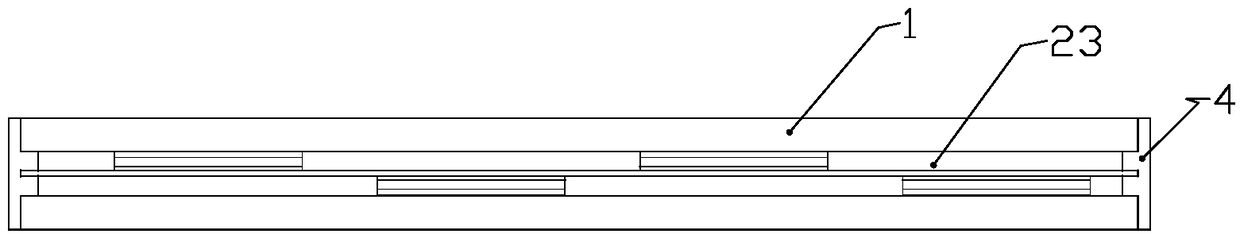

[0043] like Figure 1 to Figure 7 , the present invention provides in a specific embodiment, a kind of energy supply lithium battery pack, comprises electric core 1, battery pack housing 3 and separator 2, wherein separator 2 is made of foam 21 and metal framework 22 Composite.

[0044] The shell 3 is preferably an aluminum alloy shell.

[0045] In one example, the foam 21 may have a desirable thermal stability, flexibility, and explosion-proof properties. In addition, the main surface layers on both sides of the foam may include a fabric support such as non-woven fabric, glass fiber cloth, and the like. Specifically, the fabric support is disposed on the foam to enhance its strength, impact resistance, and formability.

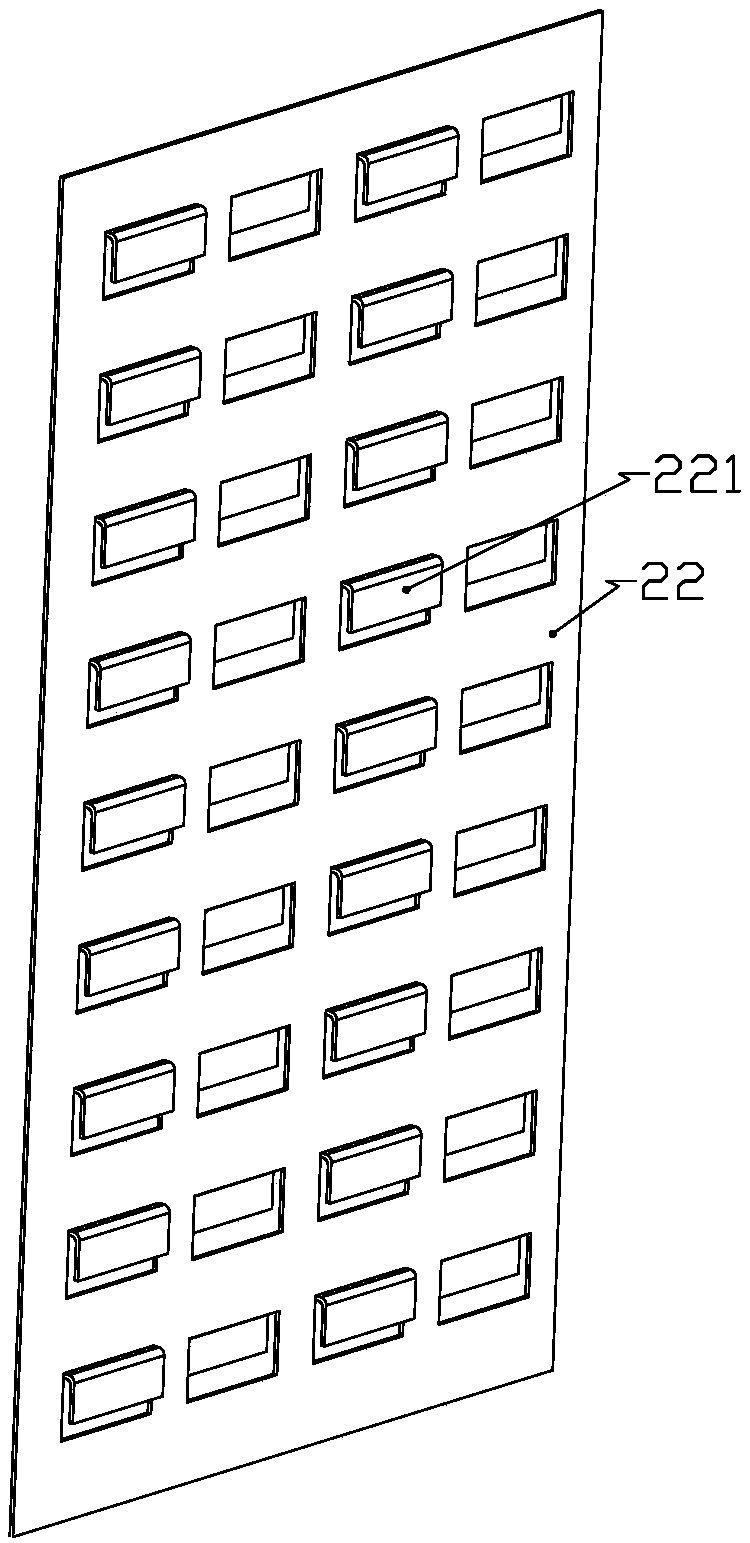

[0046] It also includes an alloy skeleton 22. The alloy skeleton is a metal stamping part. An alloy flat plate, especially a flat plate with good stamping performance, is used to form protrusions protruding to both sides by stamping. The protrusions are Z-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com