A kind of method that uses natural plant extract as raw material to prepare maillard reactant for tobacco

A technology of Maillard reactants and natural plants, which is applied in the preparation of tobacco, tobacco, application, etc., can solve the problem that the application effect of Maillard reactants cannot be well highlighted, the aroma style characteristics of reactants are not obvious enough, and the smoke aroma is rich Insufficient sexuality and harmony, etc., to achieve the effect of increasing the sweetness of the mouth, obvious aroma characteristics, and enhancing the aroma quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

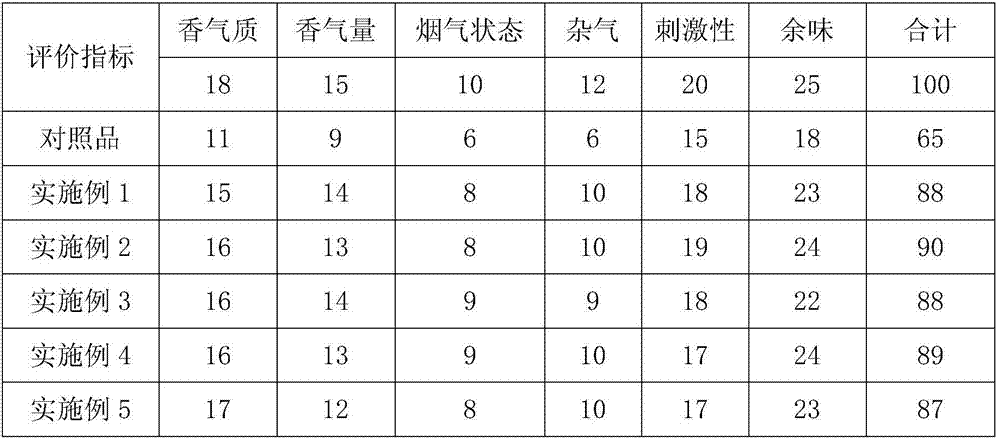

Examples

example 1

[0022] Example 1, a method for preparing tobacco Maillard reactants with natural plant extracts as raw material, using fresh grapes as raw material, the specific steps are as follows:

[0023] (1) Moderately crush fresh grapes, add 5 times the amount of 10% ethanol aqueous solution, reflux extraction at 60°C for 4 hours, and coarsely filter to obtain the initial grape extract;

[0024] (2) Add 0.20% of its weight of Bacillus subtilis α-amylase (activity unit: 6000U / g) to the initial grape extract, and continue enzymolysis for 2.5 hours at 80°C, pH value 5.5, stirring speed 150r / min ;

[0025] (3) Utilize the 100nm pore size inorganic ceramic filter membrane to filter the enzymatic solution to obtain the membrane filtrate;

[0026] (4) Add 0.50% of its weight neutral protease (activity unit: 50000U / g) to the membrane filtrate, and continue enzymatic hydrolysis for 1h at 60°C, pH value 7.2, stirring speed 100r / min;

[0027] (5) After the enzymolysis is finished, add 1.5 times ...

example 2

[0031] Example 2, a method for preparing the maillard reactant for tobacco with natural plant extracts as raw material, using Fructus Lycium barbarum as raw material, its specific steps are as follows:

[0032] (1) Properly crush the wolfberry fruit, add 7 times the amount of 15% ethanol aqueous solution, reflux extraction at 60°C for 6 hours, and coarsely filter to obtain the initial wolfberry extract;

[0033] (2) Add 0.15% by weight of Bacillus subtilis α-amylase (activity unit: 6000 U / g) to the primary extract of Lycium barbarum, and continue enzymatic hydrolysis for 4 hours at 85°C, pH value 6.5, and stirring speed 90r / min;

[0034] (3) Utilize the 100nm pore size inorganic ceramic filter membrane to filter the enzymatic solution to obtain the membrane filtrate;

[0035] (4) Add 0.55% of its weight neutral protease (activity unit: 50000U / g) to the membrane filtrate, and continue enzymatic hydrolysis for 1.5h at 55°C, pH value 6.6, stirring speed 120r / min;

[0036] (5) Af...

example 3

[0040] Example 3, a method for preparing maillard reactants for tobacco with natural plant extracts as raw material, using licorice as raw material, the specific steps are as follows:

[0041] (1) Properly crush the licorice, add 7 times the amount of 25% ethanol aqueous solution, reflux extraction at 80° C. for 4 hours, and coarsely filter to obtain the initial licorice extract;

[0042] (2) Add 0.35% by weight of Bacillus subtilis α-amylase (activity unit: 6000 U / g) to the initial liquorice extract, and continue enzymolysis for 2 hours at 90°C, pH value 6.8, stirring speed 150r / min;

[0043] (3) Utilize the 100nm pore size inorganic ceramic filter membrane to filter the enzymatic solution to obtain the membrane filtrate;

[0044](4) Add 0.30% of its weight neutral protease (activity unit: 50000U / g) to the membrane filtrate, and continue enzymatic hydrolysis for 1.5h at 52°C, pH value 7.5, stirring speed 90r / min;

[0045] (5) After the enzymolysis is finished, add 95% ethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com