Device for gradually adsorbing and purifying ammonia gas and method for utilizing device to purify ammonia gas

An ammonia gas and adsorption column technology, which is applied in the field of low-purity ammonia gas purification, can solve the problems of high price, large product investment, and high unit price, and achieve the effects of increasing the depth of purification, purifying the environment, and improving the utilization rate of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

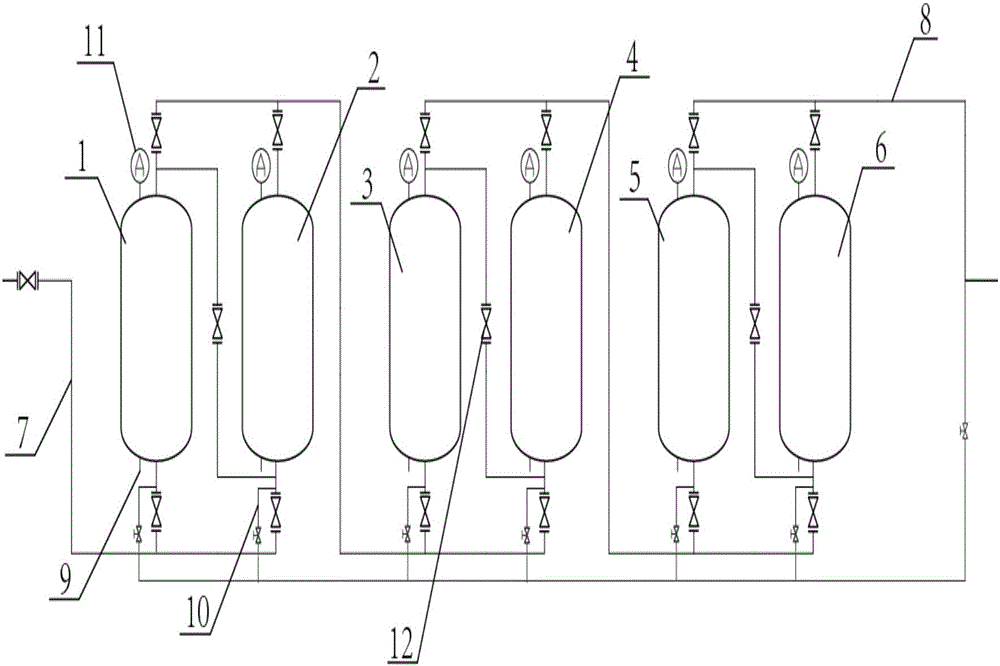

[0034] See attached figure 1 , the device for stepwise adsorption and purification of ammonia includes No. 1 adsorption column 1, No. 2 adsorption column 2, No. 3 adsorption column 3, No. 4 adsorption column 4, No. 5 adsorption column 5, and No. 6 adsorption column 6; The top of the adsorption column communicates with the bottom of the No. 2 adsorption column, the bottom of the No. 3 adsorption column, and the bottom of the No. 4 adsorption column; the top of the No. 2 adsorption column communicates with the bottom of the No. 3 adsorption column and the bottom of the No. 4 adsorption column; The top of the adsorption column is respectively connected with the bottom of No. 4 adsorption column, the bottom of No. 5 adsorption column, and the bottom of No. 6 adsorption column; the top of the No. 4 adsorption column is respectively connected with the bottom of No. 5 adsorption column and the bottom of No. 6 adsorption column; The top of the adsorption column is communicated with th...

Embodiment 2

[0038] A device for step-by-step adsorption and purification of ammonia, which is basically the same as the first embodiment, the difference is that the porous ceramic adsorption device is an aluminum oxide adsorption device, and the filtration accuracy is 0.1 micron; The adsorption column is provided with a temperature sensor.

Embodiment 3

[0040] A method utilizing the device of embodiment two to carry out adsorption purification of high-purity ammonia, comprising the following steps:

[0041] (1) Hot nitrogen is used to replace and purge No. 1 adsorption column through the hot nitrogen inlet, and the heating temperature is raised in steps, 50°C, 100°C, 150°C, 200°C, 250°C until the top of the adsorption column The temperature at the bottom reaches 250°C and is maintained for 4 hours; the nitrogen pressure in the adsorption column is maintained at 15 psig, and the natural cooling reaches 35°C; the external insulation device of the adsorption column is removed to cool down faster to reach the required temperature; The regenerated ammonia gas was introduced at a rate of 5psig, 15psig, 30psig, 50psig, 75psig, 90psig, and 90psig in turn. When the regenerated ammonia gas was introduced each time, the temperature inside the adsorption column was 30°C; Keep the pressure in the adsorption column at 50 psig until the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com